Method for optimizing weld seam structure and properties of HFW(High Frequency Welded) pipes

A welded pipe and performance technology, applied in the field of optimizing the structure and performance of the weld of HFW welded pipe, can solve problems such as reducing the quality of the weld, and achieve the effect of improving the toughness of the weld, improving the corrosion resistance and plastic toughness, and improving the structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

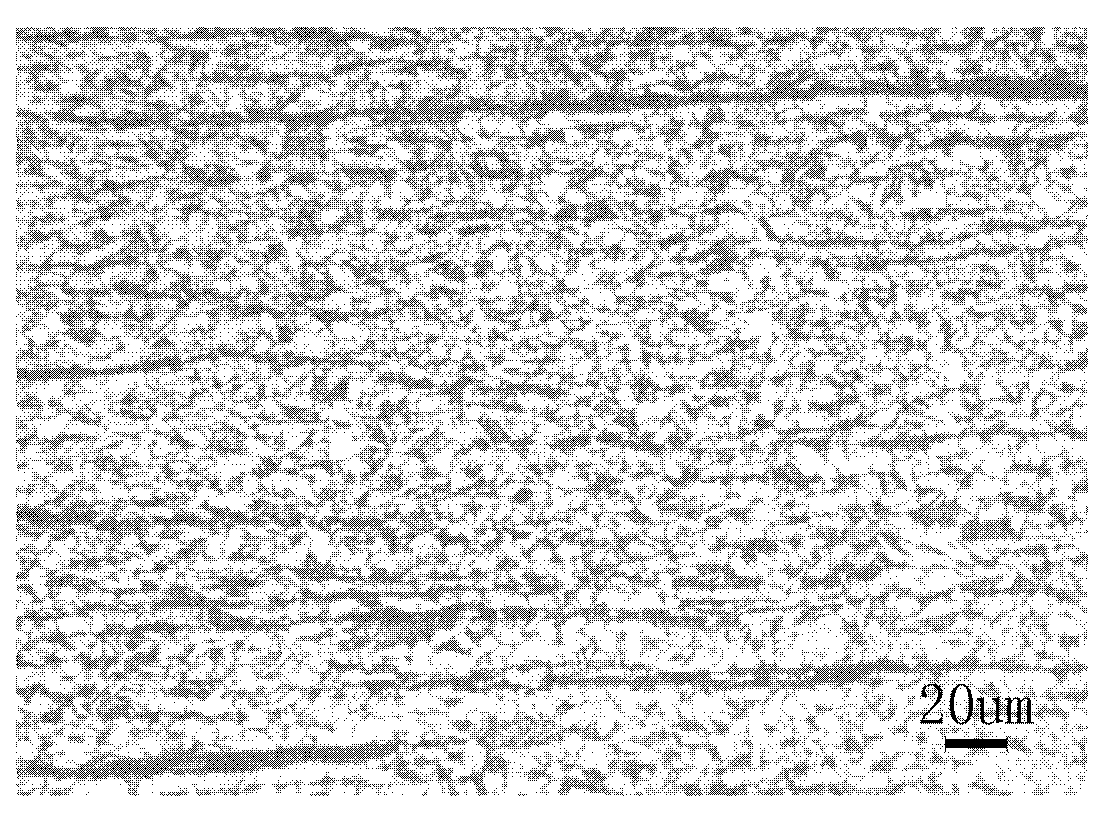

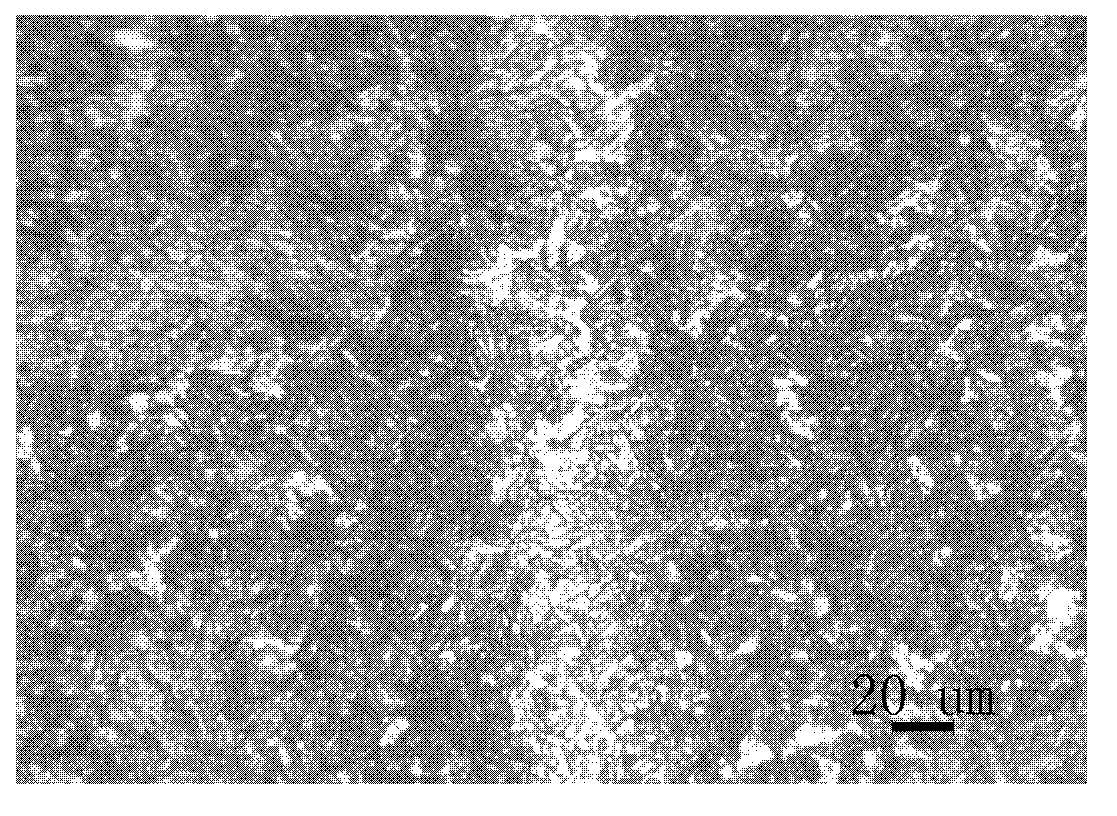

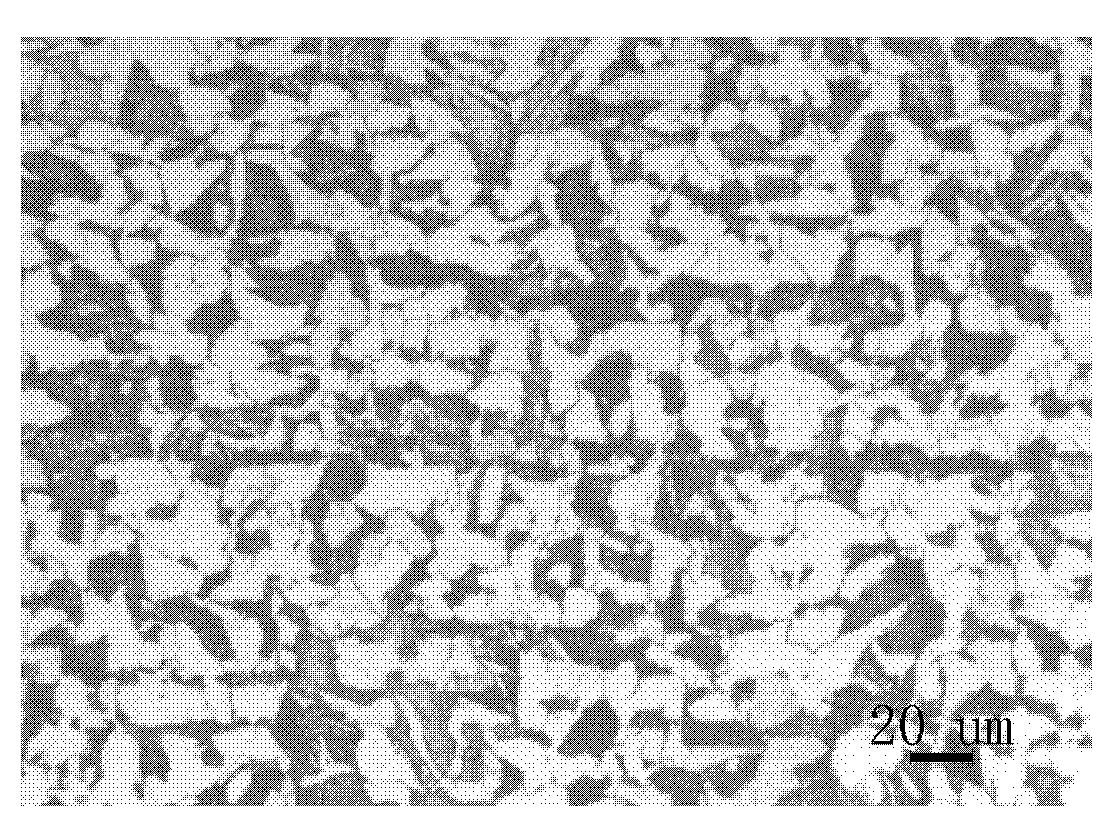

Image

Examples

Embodiment Construction

[0017] 1. The medium frequency induction furnace is used to carry out overall continuous, rapid heating and rapid heat penetration of the HFW welded pipe with a specification of Φ193.7×7.41mm and removal of internal and external burrs. The heating rate is 40-100°C / s, so that the HFW welded pipe exits the medium frequency induction furnace outlet The temperature reaches 975±15℃;

[0018] 2. The HFW welded pipe enters the hot rolling reducing unit at a speed of 0.48m / s at a temperature of 975±15°C and uses 12 extrusion rolls for thermomechanical rolling;

[0019] 3. Adjust the extrusion force of the extrusion roller so that the specification of the HFW welded pipe exiting the hot rolling reducing unit is reduced to Φ139.7×7.72mm;

[0020] 4. The HFW hot-rolled reducing pipe enters the subsequent processing process.

[0021] The chemical composition of the steel alloy material for HFW welded pipes is: 0.295% C, 0.252% Si, 1.20% Mn, 0.019% P, 0.008% S, 0.019% Cr, and the balance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com