Welding technology of P92 steel submerged automatic arc welding for power station boiler

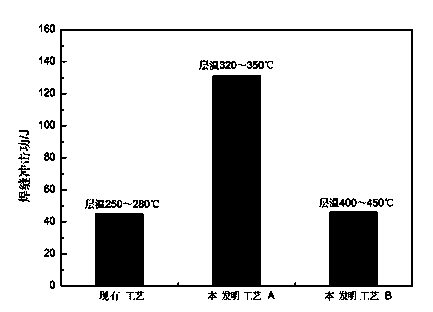

A technology for automatic submerged arc welding and power station boilers, applied in arc welding equipment, welding media, welding equipment, etc., can solve the problems of reduced production efficiency, prolonged single pause time, frequent pauses in the welding process, etc., to improve the welding seam. Toughness, the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

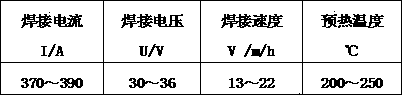

[0014] One, technological principle of the present invention is based on following considerations:

[0015] (1) The hot crack tendency of P92 submerged arc welding seam is large and the toughness is low, which is mainly due to improper selection of welding materials. At present, the welding wire whose composition is equivalent to that of P92 steel is generally selected, typical grades such as 9CrWV and Thermanit MTS616 submerged arc welding wire. This type of wire has a high C content (typically 0.11wt.%), and the addition of about 0.5-0.8 wt.% Ni element suppresses the formation of δ-ferrite. The disadvantage is that the high C content of the welding wire increases the thermal crack sensitivity of the weld, and the addition of Ni appears to be insufficient at high temperatures, resulting in the formation of δ-ferrite in the weld, but continue to increase the addition of Ni in the welding wire make A again C1 Excessive reduction will affect the selection of post-weld heat tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| weld impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com