Supersonic vibration-assisted laser cladding composite processing equipment

A technology of ultrasonic vibration and auxiliary laser, applied in the field of laser surface processing, can solve the problem of high crack sensitivity, and achieve the effect of improving crack sensitivity, improving wear resistance and extremely fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and example the present invention will be further described:

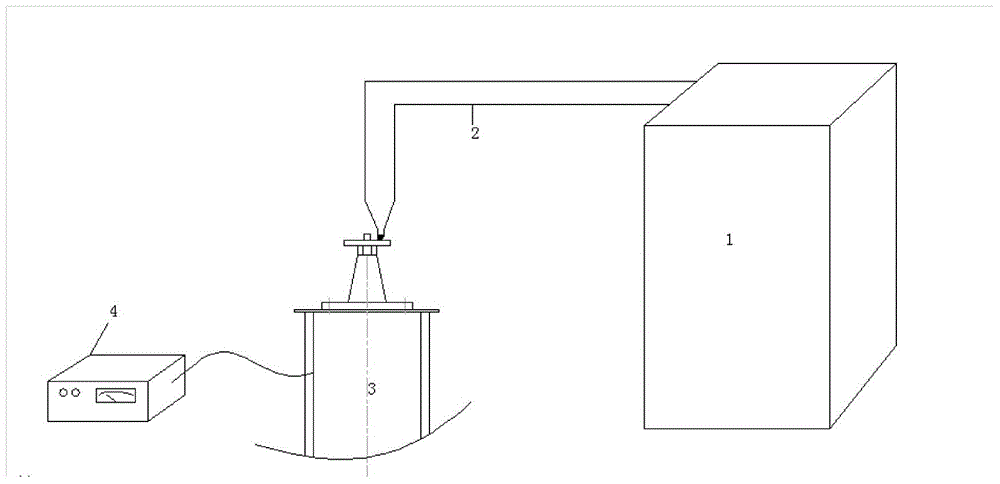

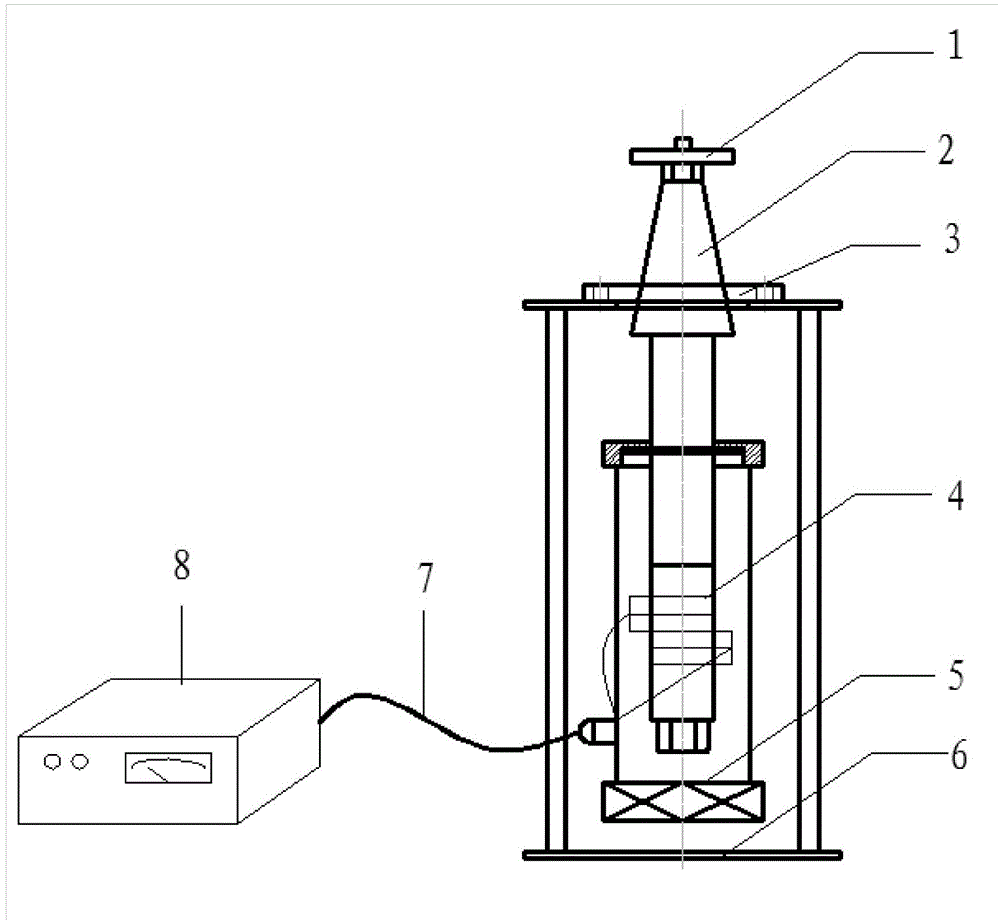

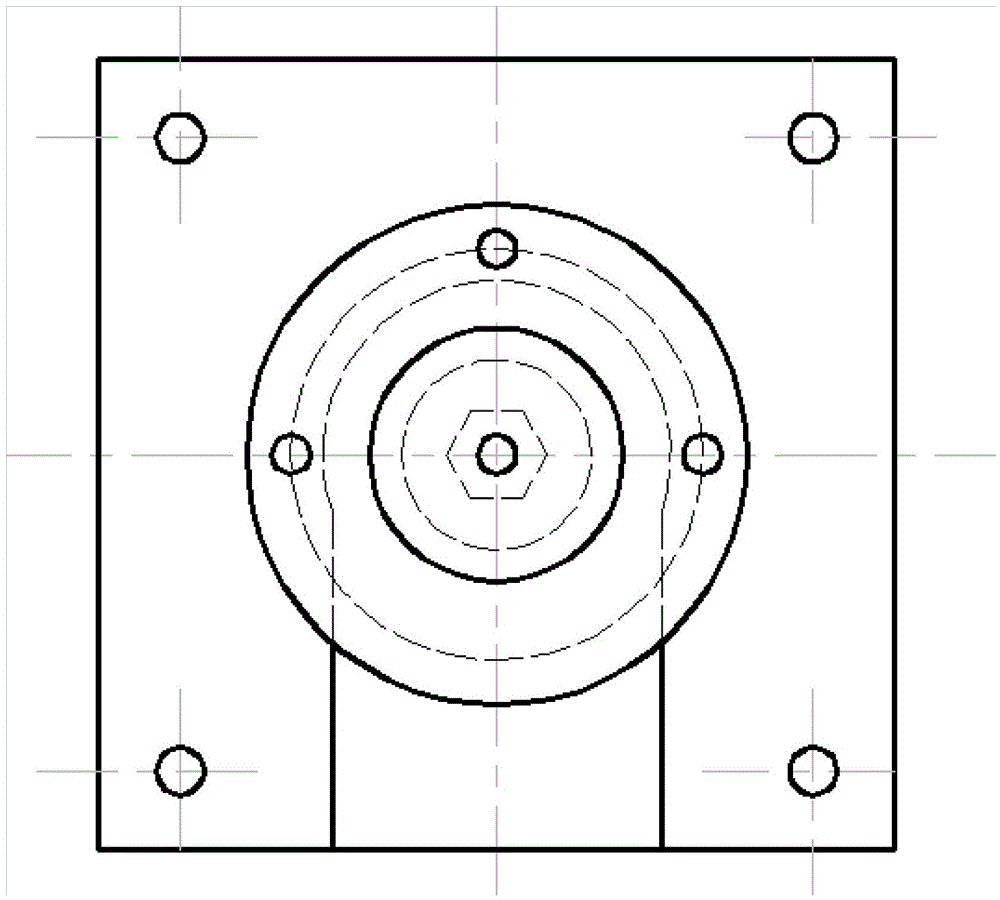

[0034] Such as figure 1 and figure 2 As shown, the ultrasonic vibration-assisted laser cladding composite processing device of the present invention includes a test block [1], a horn [2], a flange [3], a transducer [4], and a cooling fan [5] , column bracket [6], cable [7] and ultrasonic generator [8]. Grind the surface of the substrate test block [1] to be clad flat, then wipe the surface with acetone to remove oil stains, fix the test block [1] and the horn [2] with bolts, and then use the cable [7] to generate ultrasonic waves Device [8] is connected with transducer [4]. The powder to be clad is preset on the surface of the test block, the laser head is moved to the position to be clad, and the ultrasonic generator and laser are turned on at the same time. Turn off the ultrasonic generator after cladding to achieve the purpose of refining the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com