P92 steel submerged arc welding wire

A technology of chemical composition and mass percentage, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of reduced phase transition point, affect application, limited effect, etc., and achieve the effect of improving weld toughness

Active Publication Date: 2011-09-21

DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

View PDF4 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

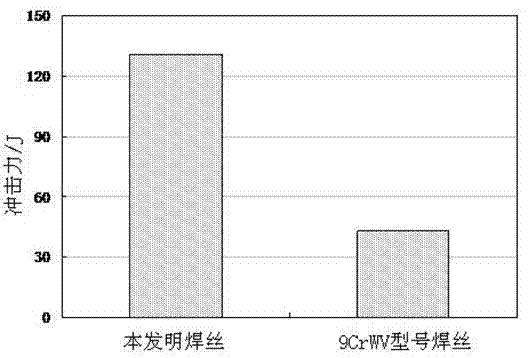

However, the weld seam toughness of submerged arc welding is low, which affects the application of submerged arc welding, an efficient welding method, in boiler manufacturing.

At present, most P92 steel submerged arc welding wire adopts alloying design similar to P92 steel composition, and some nickel and manganese elements are added on the basis of P92 steel to improve weld toughness, but the effect is limited, and if the content of nickel and manganese elements is too high Assembly leads to Ac 1 The phase transition point is significantly reduced, which affects the implementation of the post-weld heat treatment process and adversely affects the high-temperature performance of the welded joint (Brühl.Verhalten des 9%-ChromstahlesX10CrMoVNb91 und seiner Schweiβverbindungen im Kurz-undLangzeitversuch.Dissertation, Graz 1989)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

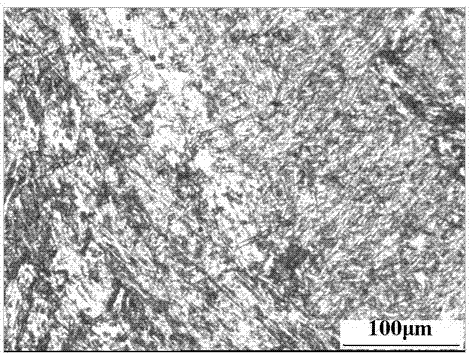

[0015] Example: Take C: 0.08%, Si: 0.30%, Mn: 0.78%, P: 0.007%, S: 0.003%, Cr: 9.50%, Mo: 0.30%, V: 0.2%, W: 1.52% by mass percentage %, Ni: 0.52%, Nb: 0.033%, Co: 0.91%, B: 0.0038%, N: 0.057%, and the balance is Fe, which is smelted by conventional electric furnace smelting method, and drawn on a wire drawing machine after annealing to make the diameter It is a welding wire of Φ2.4mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

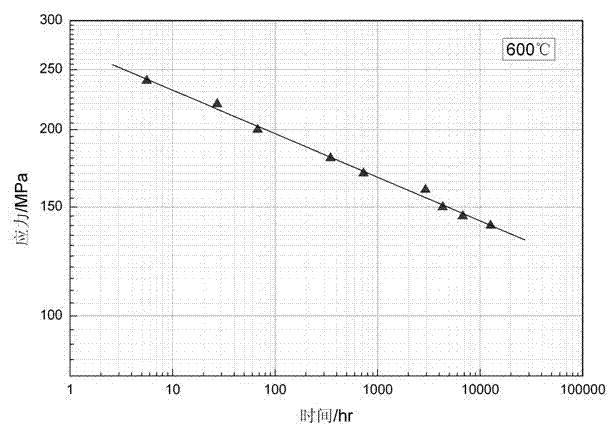

The invention discloses a P92 steel submerged arc welding wire, which contains the following chemical components in percentage by mass: 0.06 to 0.08% of C, not less than 0.40% of Si, 0.4-1.0% of Mn, not less than 0.015% of P, not less than 0.015% of S, 9.0 to 10% of Cr, 0.3 to 0.6% of Mo, 0.15 to 0.25% of V, 1.5 to 2.0% of W, not less than 0.6% of Ni, 0.03 to 0.07% of Nb, 0.8 to 1.0% of Co, 0.001to 0.05% of B, 0.03 to 0.07% of N, and the balance of Fe. The welding wire is used in the submerged arc welding, on the premise of guaranteeing high temperature performance of a welding joint, the toughness of a weld seam is increased, and the application of a highly efficient welding method of the submerged arc in the boiler production is ensured.

Description

technical field [0001] The invention relates to a welding material for P92 steel, in particular to a welding material applied to a submerged arc welding process for P92 steel. Background technique [0002] P92 steel is a new type of martensitic heat-resistant steel obtained by adding a certain amount of tungsten element, appropriately reducing the content of molybdenum element, and adding trace boron element on the basis of P91 steel. It is widely used in the main steam pipe of ultra-supercritical boilers. , headers and other thick-walled pipes. As a mechanized welding method, submerged arc welding has the advantages of high production efficiency, high weld quality and good working conditions, and has significant technical and cost advantages in the manufacture of boiler components. However, the weld seam toughness of submerged arc welding is low, which affects the application of submerged arc welding, an efficient welding method, in boiler manufacturing. At present, most ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/30

Inventor 王学潘乾钢陶永顺曾会强刘自军刘洪

Owner DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com