Method for preparing flexible carbon nano tube transparent conductive thin-film material and electrodeposition device

A technology of transparent conductive film and carbon nanotubes, which is applied to the device for coating liquid on the surface, electrolytic coating, metal material coating process, etc., can solve the problem of poor adhesion between film and substrate, which limits the application of flexible transparent conductive film Difficult to achieve film continuity, large-area preparation, etc., to achieve the effect of small surface roughness, good transparent conductivity, and easy control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

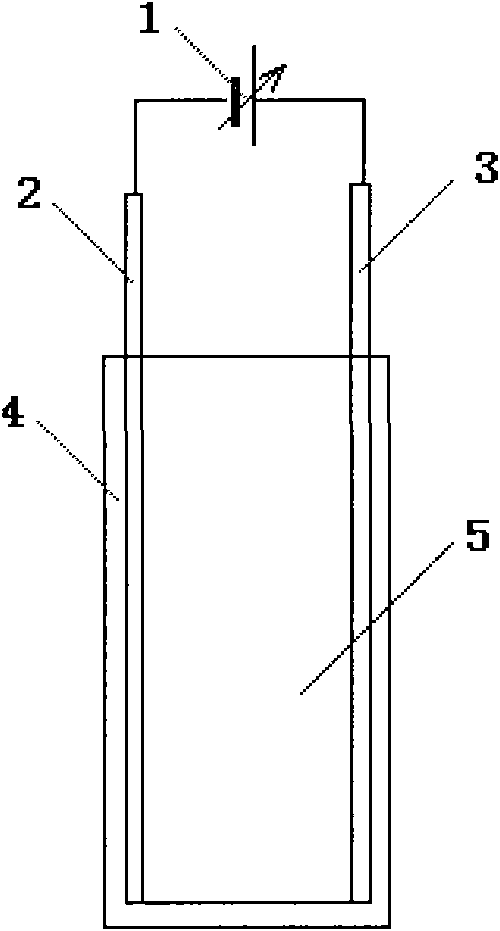

[0028] Such as figure 1 As shown, the electrodeposition device includes an adjustable regulated DC power supply 1 and a rectangular electrophoresis tank 4 containing electrode sheets. The two plates in the electrophoresis tank 4: the positive plate 3 and the negative plate 2 are all made of stainless steel inert electrodes, the two plates are parallel to each other, and the area ratio of the positive and negative electrodes is 1:1-1:5. The carbon nanotube plating solution 5 is placed in the electrophoresis tank 4, the carbon nanotubes are deposited on the positive plate 3 to form a film, and the deposition surface is polished, and the surface roughness is less than 10nm.

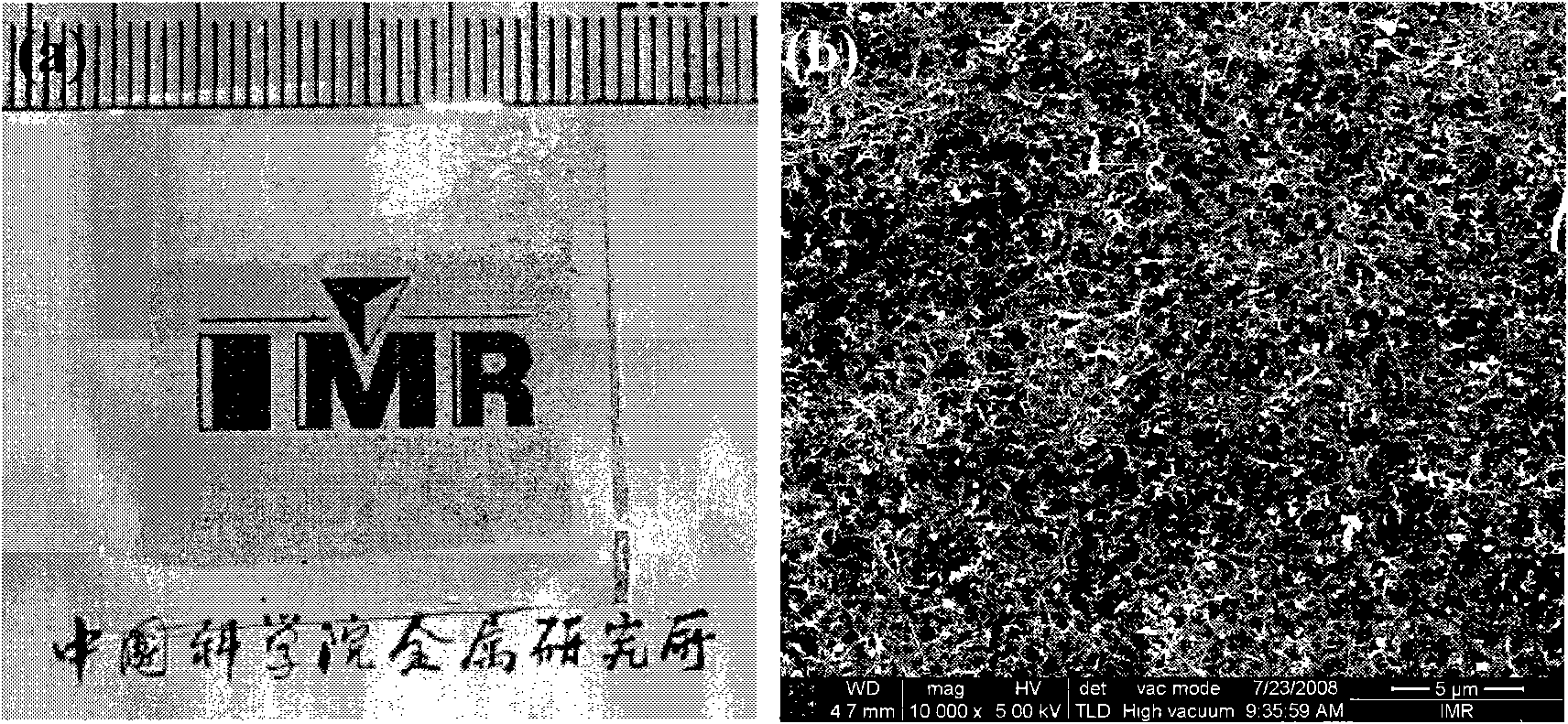

[0029] Use the anionic surfactant sodium dodecyl sulfate (SDS) to separate the single-walled carbon nanotubes (in this embodiment, the specifications of the single-walled carbon nanotubes are: diameter 0.8-1.6nm, aspect ratio: 800-5000, weight purity 92%, volume resistivity 145S / cm) dispersed in aqueous sol...

Embodiment 2

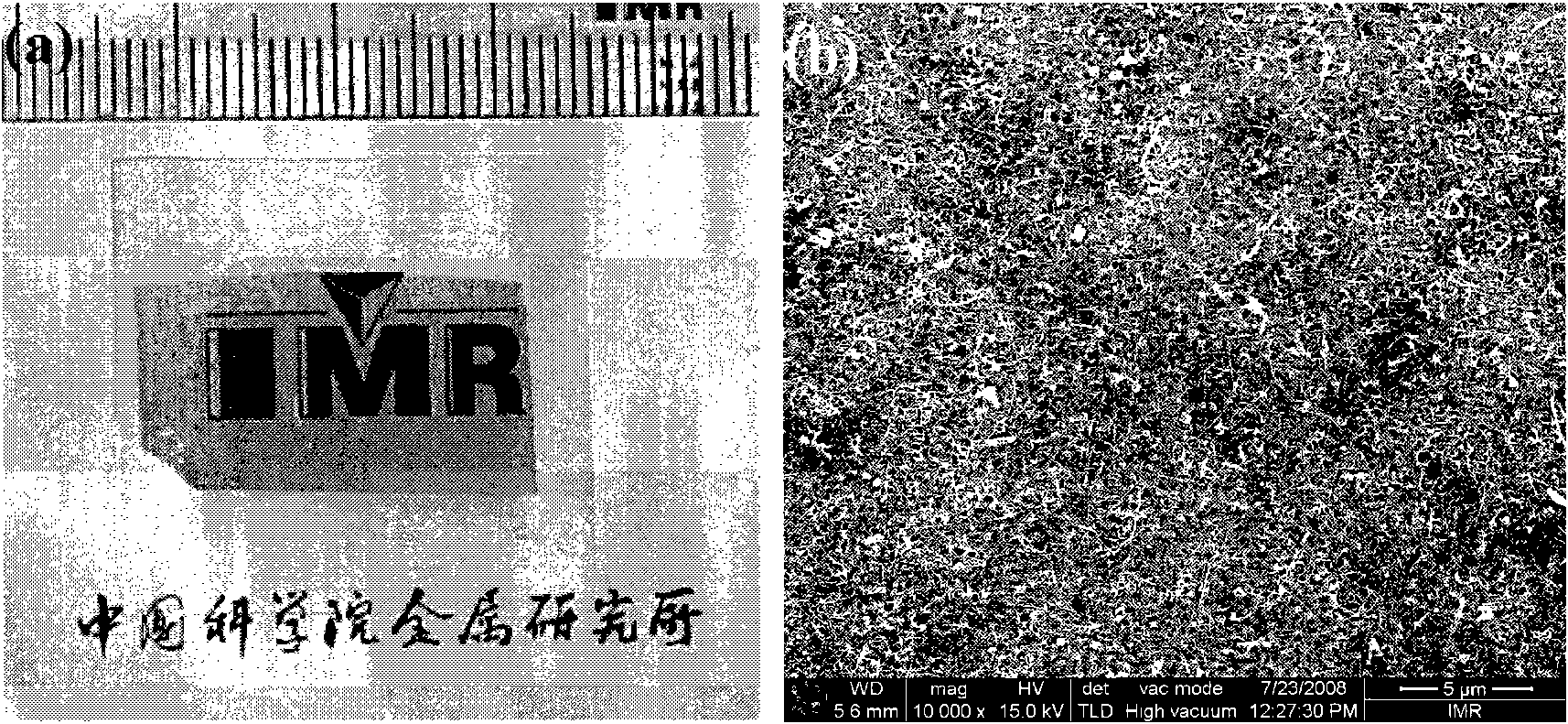

[0032] Electrodeposition devices such as figure 1 .

[0033] Use the ionic surfactant sodium dodecylsulfonate (SDS) to separate the single-walled carbon nanotubes under the action of ultrasonic waves (in this embodiment, the specifications of the single-walled carbon nanotubes are: diameter 0.8~1.6nm, aspect ratio : 800~5000, weight purity 92%, volume resistivity 145S / cm) dispersed in aqueous solution, the consumption ratio (mass ratio) of carbon nanotube and surfactant is 1: 5. Subsequently, the dispersion liquid was centrifuged in a centrifuge, and the supernatant liquid was taken as a plating solution, and the content of carbon tubes in the plating solution was 0.02 mg / ml. Adjust the pH value of the plating solution to 11 with ammonia water. The electric field strength used for electrodeposition is 50V / cm, and the area ratio of positive and negative electrodes is 1:1. After 40 seconds of deposition, the positive stainless steel sheet was slowly taken out, rinsed with dis...

Embodiment 3

[0036] Electrodeposition devices such as figure 1 .

[0037] Use the ionic surfactant sodium dodecylbenzene sulfonate (SDBS) to separate the single-walled carbon nanotubes (in this embodiment, the specifications of the single-walled carbon nanotubes are: diameter 0.5-1.6nm, long diameter Ratio: 800-5000, weight purity 92%, volume resistivity 145S / cm) dispersed in aqueous solution, the dosage ratio (mass ratio) of carbon nanotubes and surfactant is 1:7. Subsequently, the dispersion liquid was centrifuged in a centrifuge, and the supernatant liquid was taken as a plating solution, and the content of carbon tubes in the plating solution was 0.02 mg / ml. Adjust the pH value of the plating solution to 11 with ammonia water. The electric field strength used for electrodeposition is 50V / cm, and the area ratio of positive and negative electrodes is 1:1. After 60 seconds of deposition, the positive stainless steel sheet was slowly taken out, rinsed with distilled water and then dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electric field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com