Method for Manufacturing helix composite steel tube

A technology for composite steel pipes and manufacturing methods, applied in the direction of manufacturing tools, tubular objects, auxiliary devices, etc., can solve the problems of high manufacturing costs, cost reduction, and complex equipment, and achieve good technology promotion value, broad market prospects, and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A composite strip coil with a stainless steel thickness of 0.5mm and a carbon steel thickness of 7.5mm is used as a composite metal strip coil to produce a 219mm spiral composite steel pipe.

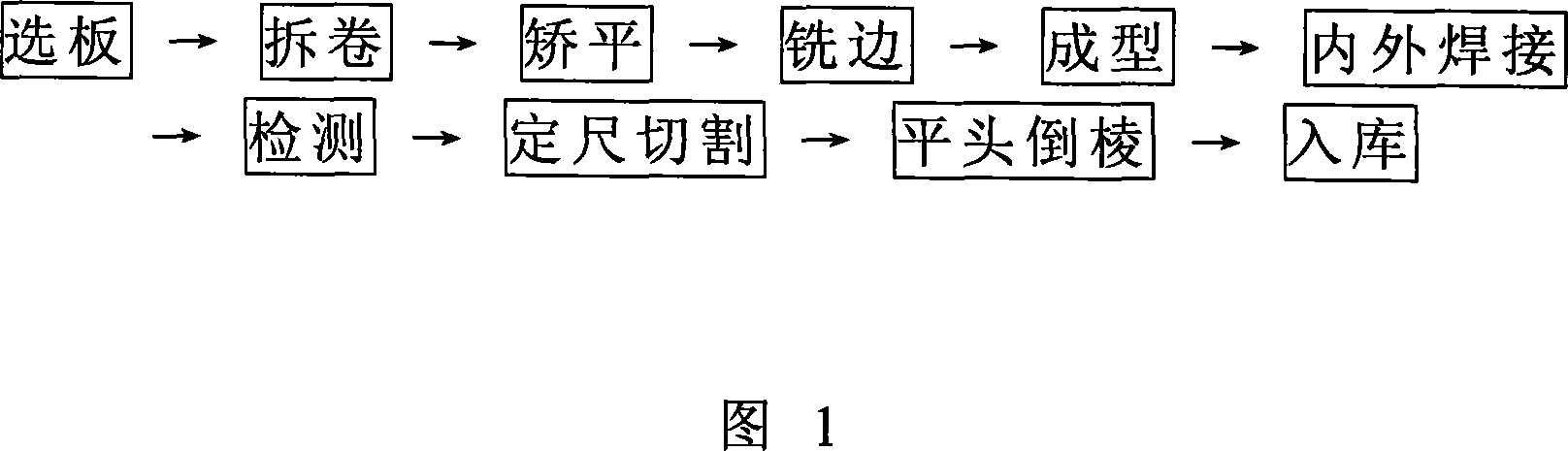

[0026] Method: Produce directly in the traditional spiral pipe making unit. After the composite steel plate is uncoiled, leveled, milled, formed, internal and external welding, testing, cut to length, and flat-end chamfered, the composite steel plate can be manufactured to 219mm Spiral composite steel pipe, in which stainless steel electrodes are used for internal welding, and ordinary carbon steel electrodes are used for external welding.

Embodiment 2

[0028] A composite strip coil with a stainless steel thickness of 2.5mm and a carbon steel thickness of 8.5mm is used as a composite metal strip coil to produce a 820mm spiral composite steel pipe.

[0029] Method: Produce directly in the traditional spiral pipe making unit. After the composite steel plate is uncoiled, leveled, milled, formed, welded inside and outside, tested, cut to length, and flat-end chamfered, the composite steel plate can be manufactured to 820mm Spiral composite steel pipe, in which stainless steel electrodes are used for internal welding, and ordinary carbon steel electrodes are used for external welding.

Embodiment 3

[0031] A composite strip with a stainless steel thickness of 3.5mm and a carbon steel thickness of 11.5mm is used as a composite metal strip to produce a 1820mm spiral composite steel pipe.

[0032] Method: Produce directly in the traditional spiral pipe making unit. After the composite steel plate is uncoiled, leveled, milled, formed, welded inside and outside, inspected, cut to length, and flat-end chamfered, 1820mm can be manufactured. Spiral composite steel pipe, in which stainless steel electrodes are used for internal welding, and ordinary carbon steel electrodes are used for external welding.

[0033] By adopting the method of the invention, various spiral composite steel pipes with nominal diameters of 219mm~1820mm can be manufactured to meet different needs of the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com