Device and method for detecting hydrogen embrittlement sensibility in high-strength steel surface treatment process

A high-strength steel, surface treatment technology, applied in the direction of applying stable tension/compression to test material strength, preparation of test samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

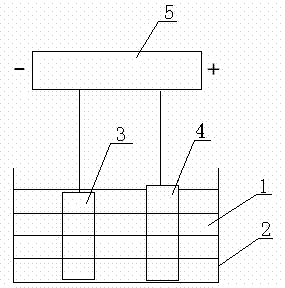

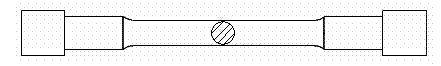

Embodiment 1

[0037] The high-strength steel 42CrMo was processed into a double-shoulder tensile high-strength steel hydrogen-filled sample 3 with a diameter of 10mm. The tensile strength of the 42CrMo high-strength steel hydrogen-filled sample 3 before hydrogen charging was 1753MPa and the maximum force was 137.6KN. With stainless steel as the electrode 4, the high-strength steel hydrogen-charged sample 3 and the stainless steel electrode 4 are respectively placed in the electrolyte tank 2 with 15% hydrochloric acid as the electrolyte 1, and the DC power supply 5 with adjustable voltage and time is respectively It is connected with the high-strength steel hydrogen-charged sample 3 and the stainless steel electrode 4, so that the high-strength steel hydrogen-charged sample 3 is used as the cathode and the stainless steel electrode 4 is used as the anode, and a hydrogen charging device is established. Simulate the electroplating process of high-strength steel surface treatment, use electrolys...

Embodiment 2

[0039] The high-strength steel 42CrMo was processed into a double-shoulder tensile high-strength steel hydrogen-filled sample 3 with a diameter of 10mm. The tensile strength of the 42CrMo high-strength steel hydrogen-filled sample 3 before hydrogen charging was 1753MPa and the maximum force was 137.6KN. With stainless steel as the electrode 4, the high-strength steel hydrogen-charged sample 3 and the stainless steel electrode 4 are respectively placed in the electrolyte tank 2 with 15% hydrochloric acid as the electrolyte 1, and the DC power supply 5 with adjustable voltage and time is respectively It is connected with the high-strength steel hydrogen-charged sample 3 and the stainless steel electrode 4, so that the high-strength steel hydrogen-charged sample 3 is used as the cathode and the stainless steel electrode 4 is used as the anode, and a hydrogen charging device is established. Simulate the electroplating process of high-strength steel surface treatment, use electrolys...

Embodiment 3

[0041] The high-strength steel 42CrMo was processed into a double-shoulder tensile high-strength steel hydrogen-filled sample 3 with a diameter of 10mm. The tensile strength of the 42CrMo high-strength steel hydrogen-filled sample 3 before hydrogen charging was 1753MPa and the maximum force was 137.6KN. With stainless steel as the electrode 4, the high-strength steel hydrogen-charged sample 3 and the stainless steel electrode 4 are respectively placed in the electrolyte tank 2 with 15% hydrochloric acid as the electrolyte 1, and the DC power supply 5 with adjustable voltage and time is respectively It is connected with the high-strength steel hydrogen-charged sample 3 and the stainless steel electrode 4, so that the high-strength steel hydrogen-charged sample 3 is used as the cathode and the stainless steel electrode 4 is used as the anode, and a hydrogen charging device is established. Simulate the electroplating process of high-strength steel surface treatment, use electrolys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com