Composite steel pipe with flange and manufacturing method thereof

A technology of composite steel pipe and flange, which is applied to the field of stainless steel lined composite steel pipe and plastic lined composite steel pipe, which can solve the problem that the thread is not easy to tighten.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

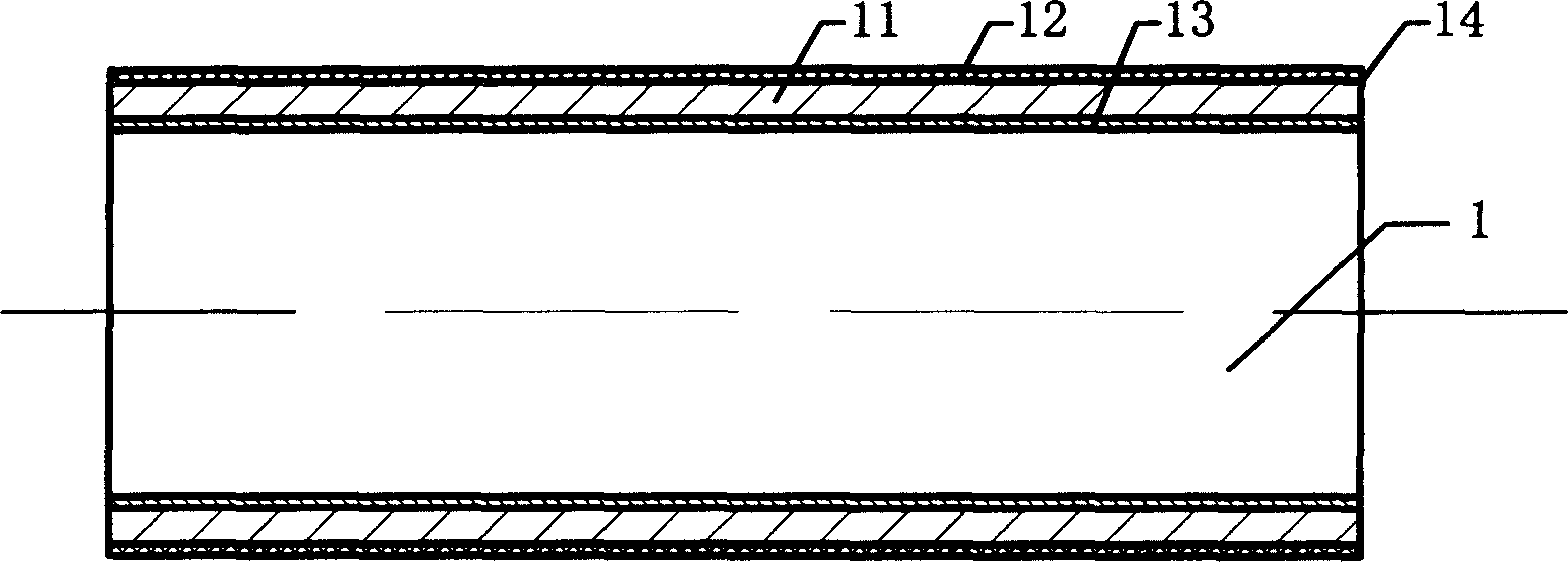

[0024] figure 1 It is a schematic cross-sectional view of the lined stainless steel composite steel pipe (1) of the present invention, (11) is an outer layer welded steel pipe, (12) is an outer galvanized layer or an outer plastic layer of an outer layer welded steel pipe, (13) is an inner liner thin Wall stainless steel pipe. Insert the thin-walled stainless steel pipe (13) into the inner hole of the outer layer welded steel pipe (11), expand the inner diameter of the lined thin-wall stainless steel pipe (13) by mechanical force or reduce the diameter of the outer layer welded steel pipe (11) by mechanical force , so that an interference fit is formed between (11) the outer layer welded steel pipe and (13) the inner layer stainless steel pipe, thereby forming a stainless steel-lined composite steel pipe (1). The surface of the welded steel pipe is hot-coated with a zinc layer (12) in a molten zinc bath at 480° C. before compounding. Or on the stainless steel clad steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com