Stainless welding rod used for underwater wet welding

A wet welding, stainless steel technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of inability to weld stainless steel materials underwater, achieve beautiful weld appearance, improve metallurgical properties, and improve Good arc ignition effect

Active Publication Date: 2013-05-08

HARBIN INST OF TECH AT WEIHAI

View PDF8 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this electrode is not an underwater stainless steel electrode, and it cannot be welded with underwater stainless steel materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

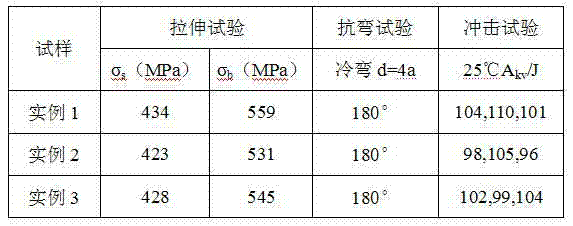

The invention discloses a high-intensity stainless welding rod used for underwater wet welding. The stainless welding rod used for underwater wet welding comprises two parts including a covering and a core wire and is characterized in that the core wire is 304L stainless steel and the covering is composed by rutile, feldspar, dolomite, carboxymethyl cellulose, manganese powder, silicon iron and nickel powder. The covering comprises, by weight, 40%-52% of rutile, 20%-30% of feldspar, 5%-10% of dolomite, 5%-10% of carboxymethyl cellulose, 5%-9% of manganese powder, 1%-4% of silicon iron and 0%-5% of nickel powder. The high-performance rod used for underwater wet welding is simple in preparation procedure, simple in arc starting in welding, stable in electric arc combustion, good in arc restarting capacity, and beautiful in shape of a gained welding joint. The strength of extension of a butt joint can reach 530 Mpa. When the cold bend angle of the butt joint is 180 degrees, the butt joint is still in good condition and no fissures occur. The stainless welding rod used for underwater wet welding has the advantages of being simple and simple in process, convenient to test and operate, high in production efficiency and the like.

Description

technical field [0001] The invention belongs to the field of welding materials, in particular to a high-performance stainless steel coated electrode for underwater wet welding with convenient operation. Background technique [0002] In recent years, the ocean has become the main field of competition for countries all over the world. The development of large oil and gas fields and coalbed methane, the construction of underwater workstations, the deployment and maintenance technology of submarine observation networks, the maintenance, disassembly and safety guarantee of offshore platforms all cover underwater welding. Technology, underwater welding technology and welding materials have become the bottleneck restricting the development of marine resources and maintenance of marine engineering. In terms of underwater welding technology, my country has initially realized dry underwater welding, but the more advanced underwater wet welding technology is far behind developed countr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/365

Inventor 郭宁刘多袁新冯吉才韩焱飞杨振林

Owner HARBIN INST OF TECH AT WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com