Synthesis of YAG luminescent material for white LED

A technology of yttrium aluminum garnet and luminescent material, which is applied in the synthesis field of yttrium aluminum garnet luminescent material for white light LED, and achieves the effects of good powder fluidity, good growth and low attenuation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the composition of matter: (Y 0.95 Ce 0.05 ) 3 Al 5 o 12 ;

[0018] Components: 15.307g of alumina, 19.619g of yttrium oxide, 1.582g of cerium oxide, 0.18g of boric acid, 0.54g of barium fluoride;

[0019] Thoroughly mix the above components evenly, among which boric acid and barium fluoride are used as flux, and are mixed and ground for 1.5 hours in a corundum ball mill jar equipped with agate balls with a diameter of 10mm, and the mixed and ground oxides are put into a corundum crucible Carry out burning for 4 hours in a high-temperature oxidizing atmosphere, and the temperature is controlled at 1500°C. The burned product is crushed and passed through a 250-mesh sieve, followed by pickling treatment, and the product after cleaning and sieving with 0.1% nitric acid solution Suction filtration until neutral, drying at 100°C and passing through a 150-mesh sieve, again put the sieved product into a corundum crucible, and burn in a nitrogen-hydrogen (5% ...

Embodiment 2

[0020] Embodiment 2: the composition of matter: (Y 0.75 Tb 0.2 Ce 0.05 ) 3 Al 5 o 12 ;

[0021] Components: 14.474g of alumina, 14.151g of yttrium oxide, 1.437g of cerium oxide, 6.336g of terbium oxide, 0.252g of boric acid, 0.360g of strontium fluoride;

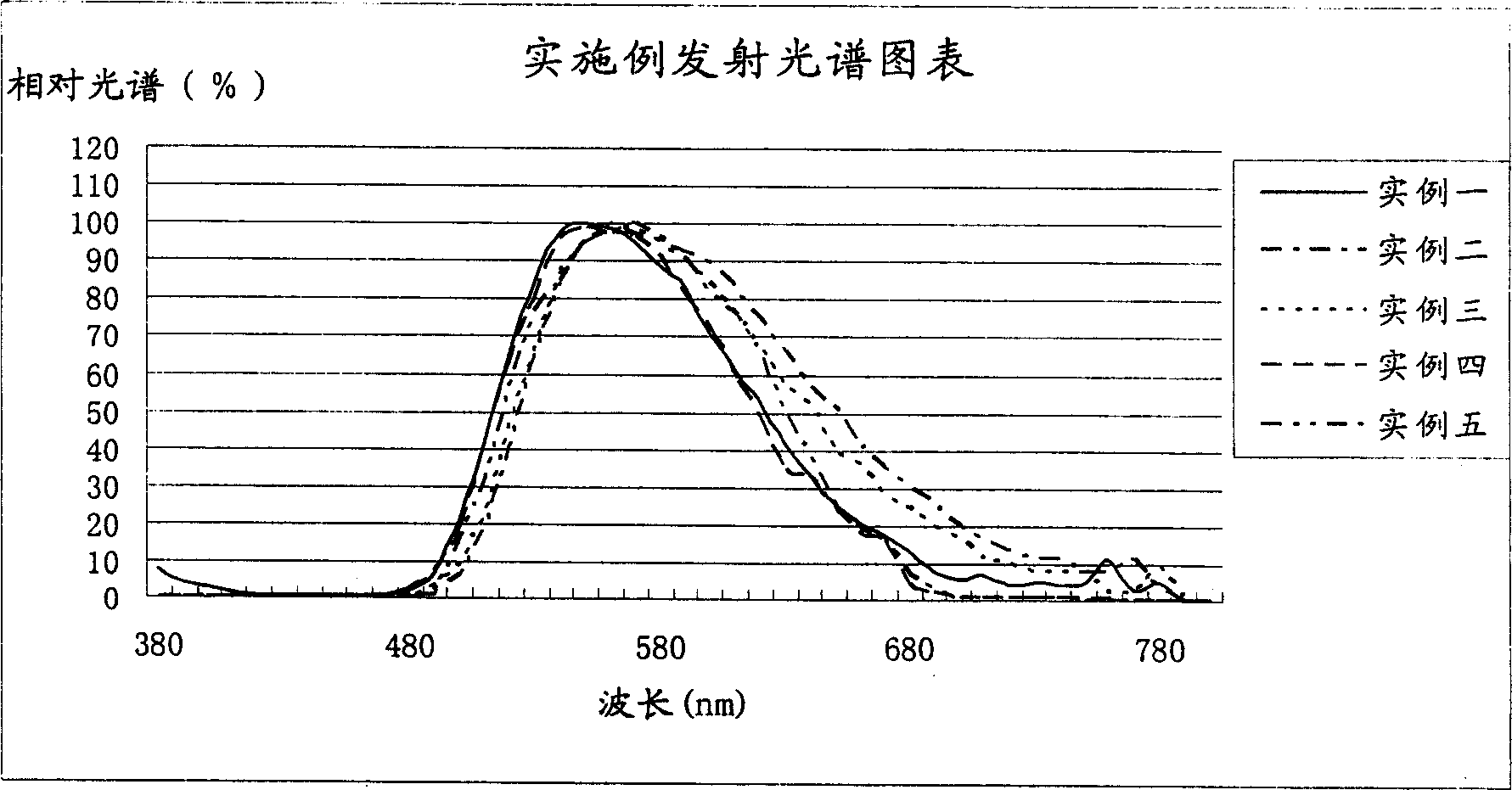

[0022] The above components were fully mixed according to Example 1, and burned twice as described in Example 1, the temperature was 1400 ° C and 1200 ° C, the time was 3 hours and 5 hours, pickling treatment and For the further treatment of the fired product, the concentration of the nitric acid solution is 0.5%, and the color of the obtained luminescent substance powder is dark yellow. The emission spectrum of the luminescent substance is shown in the accompanying drawing.

Embodiment 3

[0023] Embodiment 3: the composition of matter: (Y 0.75 Gd 0.2 Ce 0.05 ) 3 Al 5 o 12 ;

[0024] Components: 14.551g of alumina, 14.226g of yttrium oxide, 6.177g of gadolinium oxide, 1.444g of cerium oxide, 0.216g of boric acid, 0.180g of lithium chloride;

[0025] The above-mentioned components were fully mixed uniformly as described in Example 1, and burned twice as described in Example 1, the temperature was 1600 ° C and 1500 ° C, and the time was 5 hours and 4 hours respectively, pickling treatment and For the further treatment of the fired product, the concentration of the nitric acid solution is 1%, and the color of the obtained luminescent substance powder is yellow. The emission spectrum of the luminescent substance is shown in the accompanying drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com