Cr13 series overlay welding self-protection flux-cored wire

A technology of flux-cored welding wire and self-protection, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve good weld formation, good self-protection effect, and good slag coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

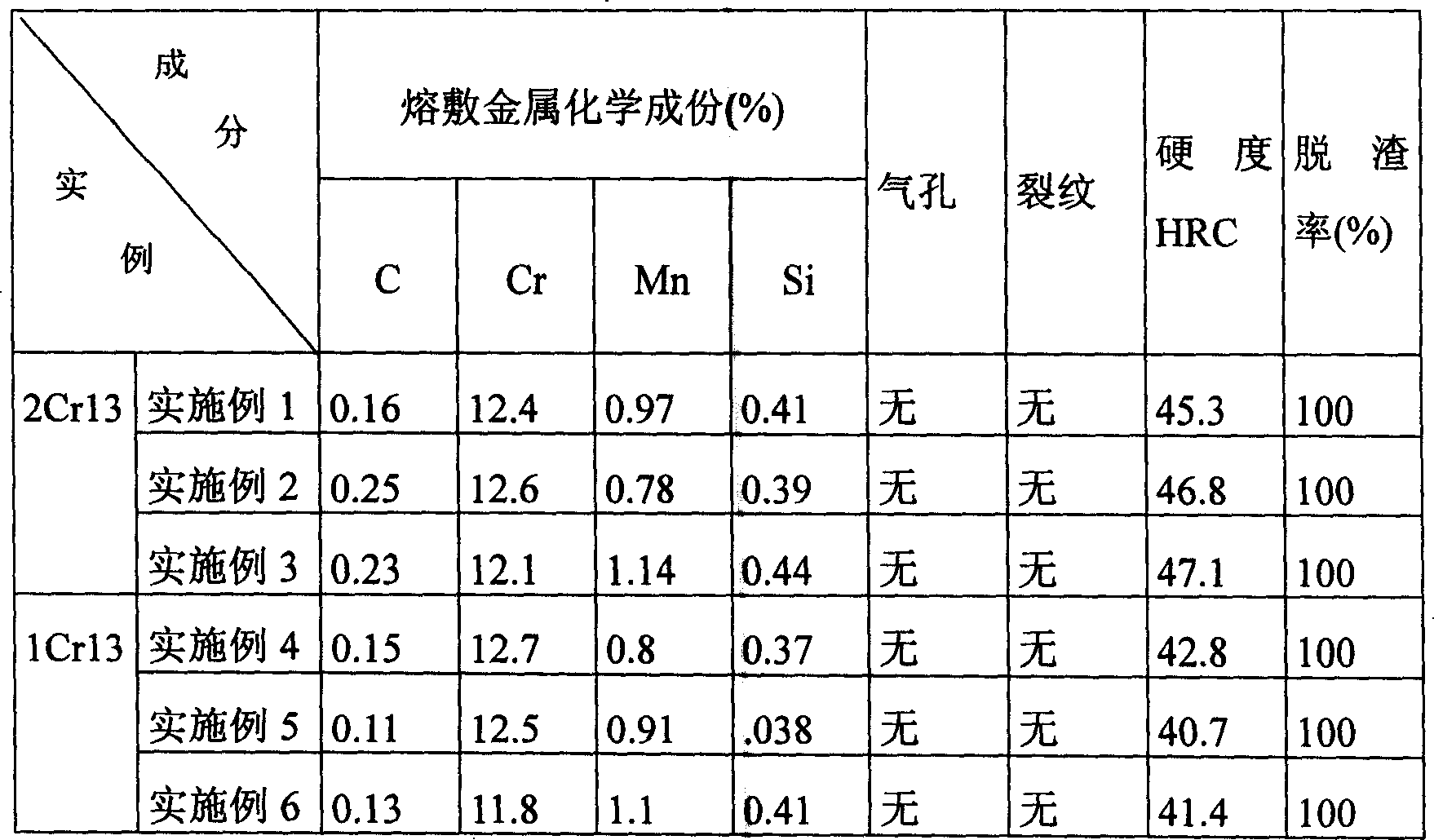

Examples

Embodiment 1

[0023] Embodiment 1: Select 14×0.3 (14 mm in width and 0.3 mm in thickness) H08 carbon steel strip. Roll it into a U shape first. 10 grams of calcium fluoride powder, 20 grams of barium fluoride powder, 1 gram of sodium carbonate powder, 30 grams of metal chromium powder, 8 grams of iron powder, 5 grams of metal manganese powder, 3 grams of high-carbon ferrochromium powder, aluminum-magnesium alloy powder 14 grams, 7 grams of potassium titanate powder, and 2 grams of magnesia powder (the powders all passed through a 60-mesh sieve) were mixed. Fully mix in the powder mixer, add to the U-shaped tank, so that the powder addition coefficient is 30%. Close the U-shaped groove so that the powder is wrapped in it. Then make it pass through the drawing dies with diameters of 4.2mm, 3.6mm, 3.3mm, 3.15mm, 2.95mm, 2.7mm, 2.5mm, 2.3mm, 2.1mm, 1.96mm, drawing and reducing the diameter one by one, and finally Make it 2.0mm in diameter. Welding without protective gas, surfacing four laye...

Embodiment 2

[0024] Embodiment 2: H08 carbon steel strip of 14×0.4 (width 14mm, thickness 0.4mm) is selected. Roll it into a U shape first. 15 grams of calcium fluoride powder, 15 grams of barium fluoride powder, 2 grams of sodium carbonate powder, 35 grams of metal chromium powder, 5 grams of iron powder, 4 grams of metal manganese powder, 6 grams of high-carbon ferrochromium powder, aluminum-magnesium alloy powder 8 grams, 5 grams of potassium titanate powder, and 5 grams of magnesia powder (the powders all passed through an 80-mesh sieve) were mixed. Fully mix in the powder mixer, add to the U-shaped tank, so that the powder addition coefficient is 20%. Close the U-shaped groove so that the powder is wrapped in it. Then make it pass through the drawing dies with diameters of 4.2mm, 3.6mm, 3.3mm, 3.15mm, 2.95mm, 2.7mm, 2.5mm, 2.3mm, 2.1mm, 1.96mm, drawing and reducing the diameter one by one, and finally Make it 2.0mm in diameter. Welding without protective gas, the welding current i...

Embodiment 3

[0025] Embodiment 3: H08 carbon steel strips of 10×0.3 (width 10 mm, thickness 0.3 mm) are selected. Roll it into a U shape first. 10 grams of calcium fluoride powder, 20 grams of barium fluoride powder, 1.5 grams of sodium carbonate powder, 40 grams of metal chromium powder, 3 grams of iron powder, 4 grams of metal manganese powder, 4.5 grams of high-carbon ferrochrome powder, aluminum-magnesium alloy powder 10 grams, 4 grams of potassium titanate powder, and 3 grams of magnesia powder (the powders all passed through a 80-mesh sieve) were mixed. Fully mix evenly in the powder mixer, add to the U-shaped tank, so that the powder addition coefficient is 25%. Close the U-shaped groove so that the powder is wrapped in it. Then make it pass through drawing dies with diameters of 2.8mm, 2.6mm, 2.4mm, 2.25mm, 2.1mm, and 1.96mm, draw and reduce the diameter one by one, and finally make the diameter reach 2.0mm. Welding without protective gas, the welding current is 250-350A, the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com