High-strength and high-toughness low alloy steel electric welding rod

A low-alloy steel, high-toughness technology, applied in the field of manual welding electrodes, to achieve the effects of no arc deviation, excellent welding performance, and stable arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Using the common manufacturing process in the welding rod production industry, the welding core is made according to the welding core formula in Table 1-1, and the coating formula is prepared according to the coating formula in Table 1-2, and the welding rod coating is prepared by dry mixing and wet mixing, and coating the welding rod coating To the core, make it shape:

[0058] Table 1-1 Solder core formula (unit: weight percentage)

[0059] C

Si

Mn

Cr

Ni

P

S

Fe

0.03

0.2

0.35

0.10

0.10

0.010

0.010

Margin

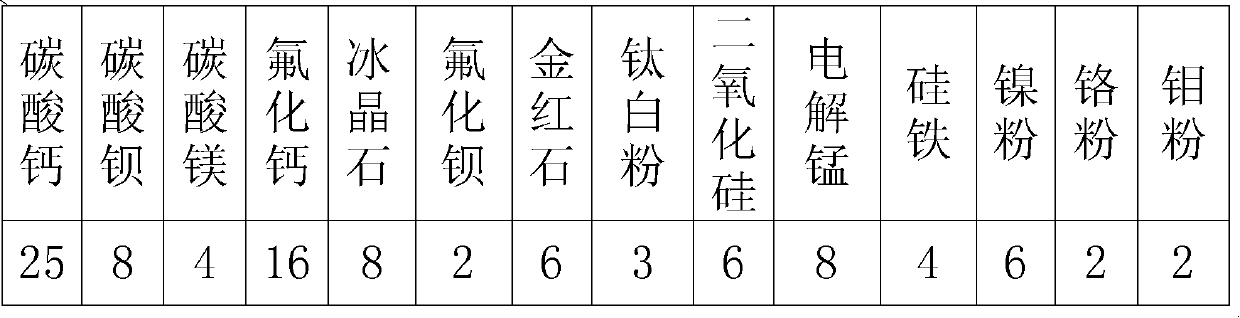

[0060] Table 1-2 Coating formula (unit: weight percentage)

[0061]

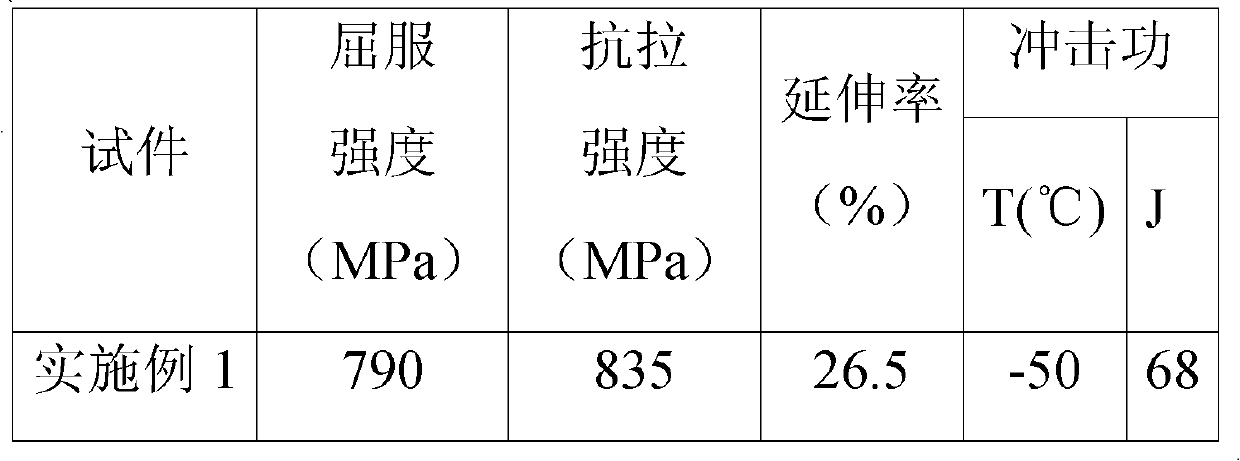

[0062] The chemical composition of the deposited metal is shown in Table 1-3, the mechanical properties are shown in Table 1-4, and the diffusible hydrogen content is shown in Table 1-5. The diffusive hydrogen is measured by gas chromatography, and the average value of two pieces is tested:

[0063] Table 1-3 Chemical composition of deposited metal (unit: percentage of elect...

Embodiment 2

[0070] Using the common manufacturing process in the welding rod production industry, the welding core is made according to the welding core formula in Table 2-1, and the coating formula is prepared according to the coating formula in Table 2-2, and the welding rod coating is prepared by dry mixing and wet mixing, and coating the welding rod coating To the core, make it shape:

[0071] Table 2-1 Solder core formula (unit: weight percentage)

[0072] C

Si

Mn

Cr

Ni

P

S

Fe

0.035

0.25

0.30

0.10

0.10

0.008

0.010

Margin

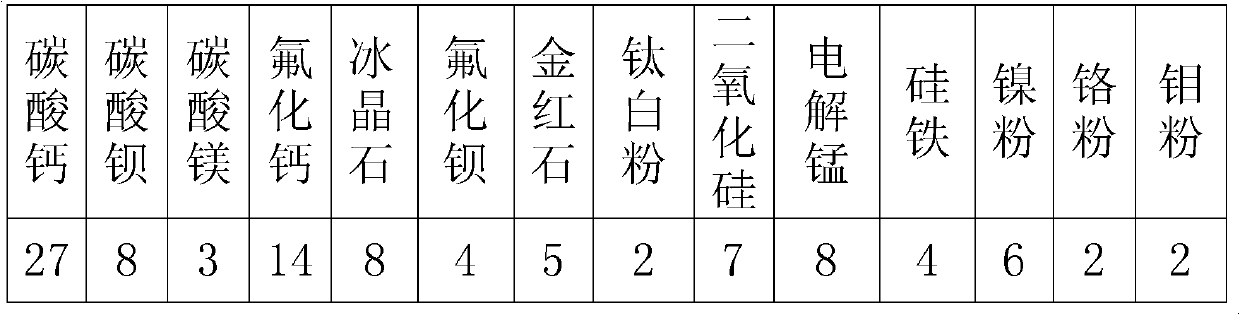

[0073] Table 2-2 Skin formula (unit: weight percentage)

[0074]

[0075] The chemical composition of the deposited metal is shown in Table 2-3, the mechanical properties are shown in Table 2-4, and the diffusible hydrogen content is shown in Table 2-5. The diffusive hydrogen is measured by gas chromatography, and the average value of two pieces is tested:

[0076] Table 2-3 Chemical composition of deposited metal (weight percentage)

[0077]...

Embodiment 3

[0083] Using the common manufacturing process in the welding rod production industry, the welding core is made according to the welding core formula in Table 3-1, and the coating formula is prepared according to the coating formula in Table 3-2, and the welding rod coating is prepared through dry mixing and wet mixing, and coating the welding rod coating To the core, make it shape:

[0084] Table 3-1 Solder core formula (unit: weight percentage)

[0085] C

Si

Mn

Cr

Ni

P

S

Fe

0.04

0.20

0.35

0.10

0.20

0.008

0.005

Margin

[0086] Table 3-2 Skin formula (unit: weight percentage)

[0087]

[0088] The chemical composition of the deposited metal is shown in Table 3-3, the mechanical properties are shown in Table 3-4, and the diffusible hydrogen content is shown in Table 3-5. The diffusive hydrogen is measured by gas chromatography, and the average value of two pieces is tested:

[0089] Table 3-3 Chemical composition of deposited metal (weight percentage)

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com