1100Mpa grade high-strength high-toughness low-alloy steel electric welding rod

A low-alloy steel, high-strength technology, used in welding media, welding equipment, metal processing equipment, etc., can solve the problem of unsatisfactory matching effect, and achieve the effect of stable arc, small splash and easy slag removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Adopt the general manufacturing process in the welding rod production industry, make the welding core according to the welding core formula in Table 1-1, prepare the welding rod coating according to the coating formula in Table 1-2 and prepare the welding rod coating by dry mixing and wet mixing, and apply the welding rod coating onto the core to form it:

[0049] Table 1-1 Solder core formula (unit: weight percentage)

[0050] C Si mn Cr Ni V P S Fe 0.066 0.007 0.44 0.007 0.014 0.002 0.007 0.006 margin

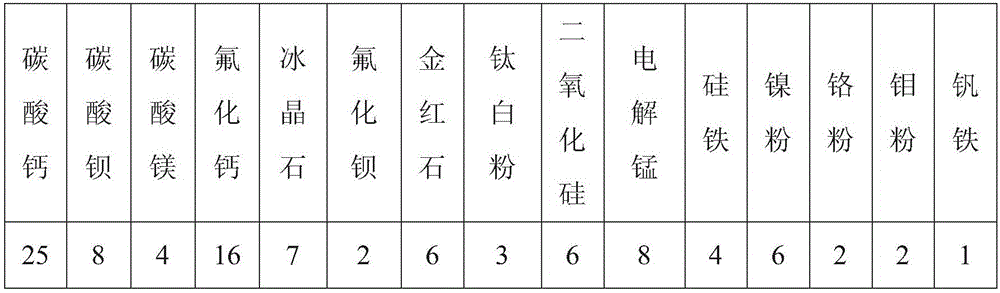

[0051] Table 1-2 drug skin formula (unit: weight percentage)

[0052]

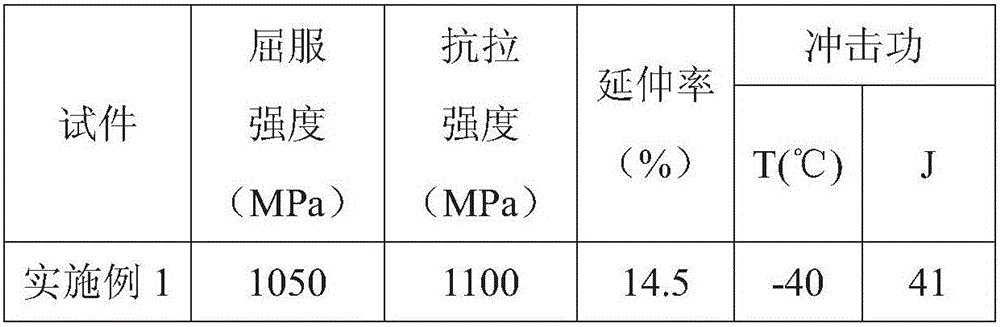

[0053] The chemical properties are tested by a spark atomic emission spectrometer, the mechanical properties are tested by a tensile testing machine, a low-temperature tank, and an impact testing machine, and the diffusible hydrogen is tested by a gas chromatography diffusive hydrogen analyzer. The chemical composition of the deposited metal is shown in Tab...

Embodiment 2

[0061] Adopt the general manufacturing process in the welding rod production industry, make the welding core according to the welding core formula in Table 2-1, prepare the welding rod coating according to the coating formula in Table 2-2 and prepare the welding rod coating by dry mixing and wet mixing, and apply the welding rod coating onto the core to form it:

[0062] Table 2-1 Solder core formula (unit: weight percentage)

[0063] C Si mn Cr Ni V P S Fe 0.066 0.007 0.42 0.007 0.013 0.002 0.006 0.006 margin

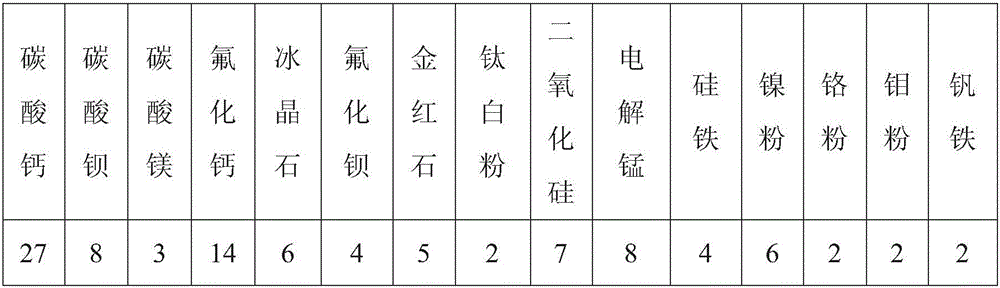

[0064] Table 2-2 Drug skin formula (unit: weight percentage)

[0065]

[0066] The chemical composition of the deposited metal is shown in Table 2-3, the mechanical properties are shown in Table 2-4, and the content of diffusible hydrogen is shown in Table 2-5. The gas chromatography is used to measure the diffusible hydrogen, and the average value of five pieces is tested:

[0067] Table 2-3 Chemical composition of deposited m...

Embodiment 3

[0075]Adopt the general manufacturing process in the welding rod production industry, make the welding core according to the welding core formula in Table 3-1, prepare the welding rod coating according to the coating formula in Table 3-2 and prepare the welding rod coating by dry mixing and wet mixing, and apply the welding rod coating onto the core to form it:

[0076] Table 3-1 Solder core formula (unit: weight percentage)

[0077] C Si mn Cr Ni V P S Fe 0.065 0.008 0.43 0.007 0.014 0.002 0.007 0.005 margin

[0078] Table 3-2 Drug skin formula (unit: weight percentage)

[0079]

[0080] The chemical properties are tested by a spark atomic emission spectrometer, the mechanical properties are tested by a tensile testing machine, a low-temperature tank, and an impact testing machine, and the diffusible hydrogen is tested by a gas chromatography diffusive hydrogen analyzer. The chemical composition of the deposited metal is shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com