Refractory steel alkaline flux-cored wire with excellent removability of slag

A technology of flux-cored welding wire and heat-resistant steel, which is applied in the welding field of low-alloy heat-resistant steel flux-cored welding wire and low-alloy heat-resistant steel, and achieves the effects of moderate thickness, excellent welding performance and improved coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

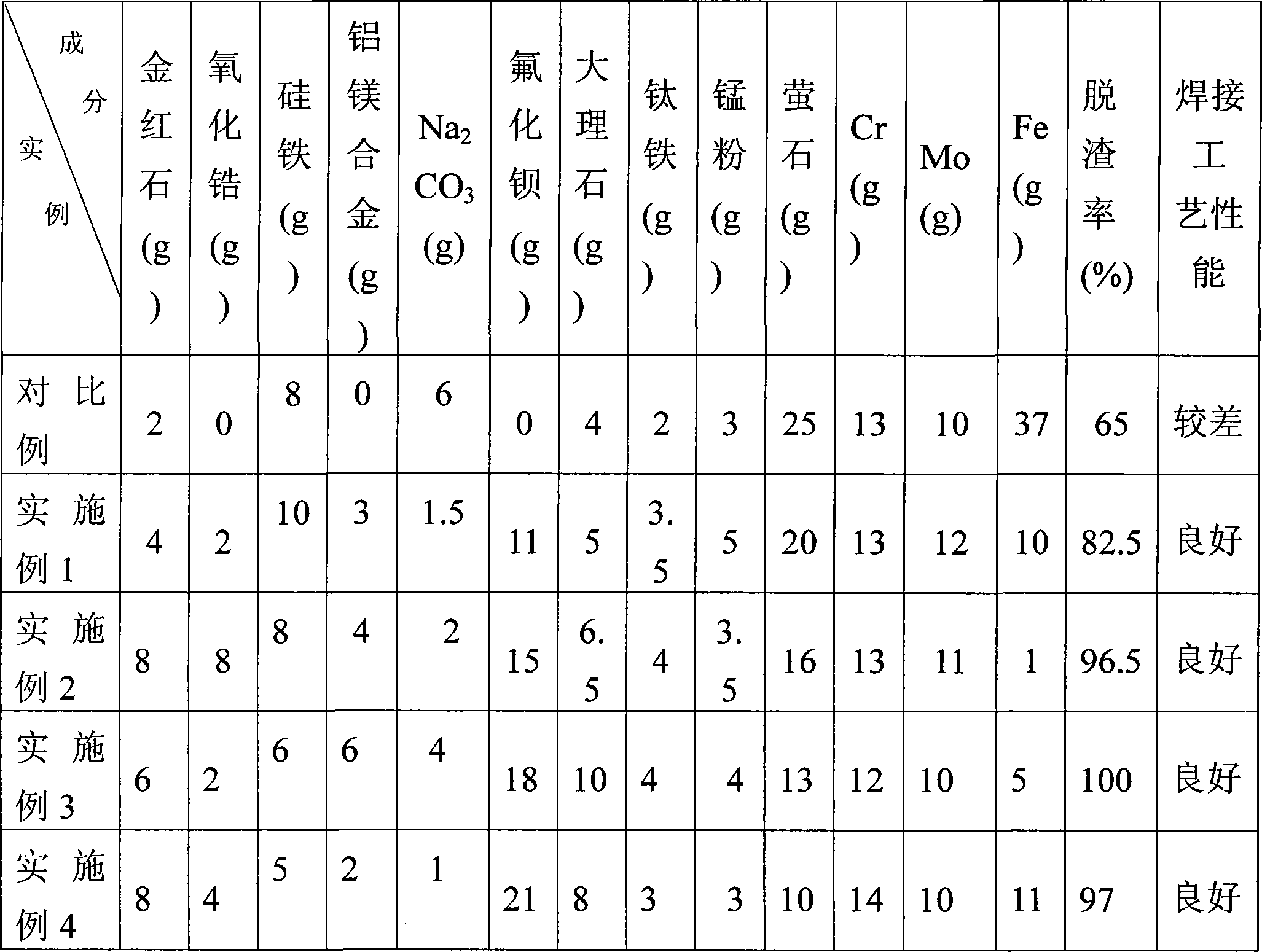

[0028] All the welding wires of the examples are produced by the "FCWM50 flux core wire drawing machine" manufactured by Kunming Heavy Machinery Factory: carbon steel strips with a width of 8-12mm and a thickness of 0.25-0.5mm are selected. First roll it into a U shape, and then add mixed medicinal powder with a particle size of 80 mesh sieves into the U-shaped groove. The filling rate of the medicinal powder (the percentage of the weight of the medicinal powder in the total weight of the welding wire) is 17-22%. Close the U-shaped groove so that the powder is wrapped in it.

[0029] The specific implementation plan is as follows:

[0030] 1. Select 8×0.25 (width 8mm, thickness 0.25mm) H08A carbon steel strip. Roll it into a U shape first. Fe molybdenum powder 12%, metal chromium powder 13%, titanium iron powder 3.5%, Fe powder 10%, silicon iron powder 10%, aluminum magnesium alloy powder 3%, manganese powder 5%, zirconia powder 2%, fluorite 20%, barium fluoride powder 11%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com