High-entropy alloy self-lubricating composite material and preparation method thereof

A high-entropy alloy and composite material technology is applied in the field of high-entropy alloy-based self-lubricating composite materials and their preparation, which can solve problems such as limitations of use conditions and achieve the effects of excellent mechanical properties and good self-lubricating properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

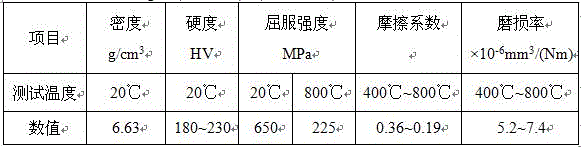

Embodiment 1

[0015] One composition is CoCrFeNi-8Ag-10(Gr / MoS 2 )-5(CaF 2 / BaF 2 )-4CeO 2 The preparation steps of the high-entropy alloy-based self-lubricating composite are as follows:

[0016] (1) Weigh CoCrFeNi quaternary high-entropy alloy powder, silver powder, graphite powder, molybdenum disulfide powder, calcium fluoride powder, barium fluoride powder and cerium oxide powder respectively according to mass percentage. Among them, silver powder is 10%, the particle size is not more than 0.038mm; graphite powder is 5%, the particle size is not more than 0.044mm; molybdenum disulfide powder is 5%, the particle size is not more than 0.005mm; calcium fluoride powder is 2%, barium fluoride powder is 3% , the particle size of the two is not greater than 0.019mm; the cerium oxide is 4%, the particle size is not greater than 0.019mm; the balance is CoCrFeNi quaternary high-entropy alloy powder, the particle size is not greater than 0.076mm. All powders were greater than 99% pure. Put th...

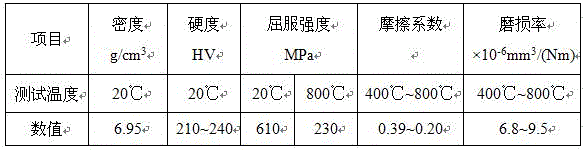

Embodiment 2

[0023] A composition of CoCrFeNi-4Ag-6 (Gr / MoS 2 )-5(CaF 2 / BaF 2 )-6CeO 2 The preparation steps of the high-entropy alloy-based self-lubricating composite are as follows:

[0024] (1) Weigh CoCrFeNi quaternary high-entropy alloy powder, silver powder, graphite powder, molybdenum disulfide powder, calcium fluoride powder, barium fluoride powder and cerium oxide powder respectively according to mass percentage. Among them, silver powder is 4%, the particle size is not more than 0.038mm; graphite powder is 3%, the particle size is not more than 0.044mm; molybdenum disulfide powder is 3%, the particle size is not more than 0.005mm; calcium fluoride powder is 2%, barium fluoride powder is 3% , the particle size of the two is not greater than 0.019mm; the cerium oxide is 6%, the particle size is not greater than 0.019mm; the balance is CoCrFeNi quaternary high-entropy alloy powder, the particle size is not greater than 0.076mm. All powders were greater than 99% pure. Put the a...

Embodiment 3

[0031] A composition of CoCrFeNi-8Ag-6 (Gr / MoS 2 )-10(CaF 2 / BaF 2 )-8CeO 2 The preparation steps of the high-entropy alloy-based self-lubricating composite are as follows:

[0032] (1) Weigh CoCrFeNi quaternary high-entropy alloy powder, silver powder, graphite powder, molybdenum disulfide powder, calcium fluoride powder, barium fluoride powder and cerium oxide powder respectively according to mass percentage. Among them, silver powder is 8%, the particle size is not more than 0.038mm; graphite powder is 3%, the particle size is not more than 0.044mm; molybdenum disulfide powder is 3%, the particle size is not more than 0.005mm; calcium fluoride powder is 4%, barium fluoride powder is 6% , the particle size of the two is not greater than 0.019mm; the cerium oxide is 8%, the particle size is not greater than 0.019mm; the balance is CoCrFeNi quaternary high-entropy alloy powder, the particle size is not greater than 0.076mm. All powders were greater than 99% pure. Put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com