Environment-friendly copper-plating-free solid welding wire surface nano composite coating

A nano-composite coating, solid welding wire technology, applied in welding media, welding equipment, welding/cutting media/materials, etc. Excellent silk performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

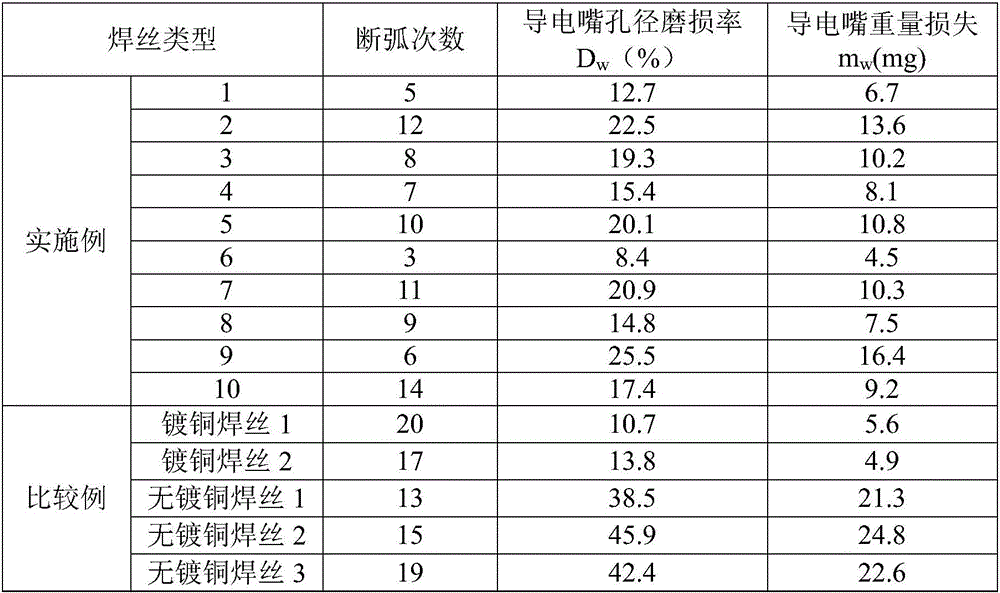

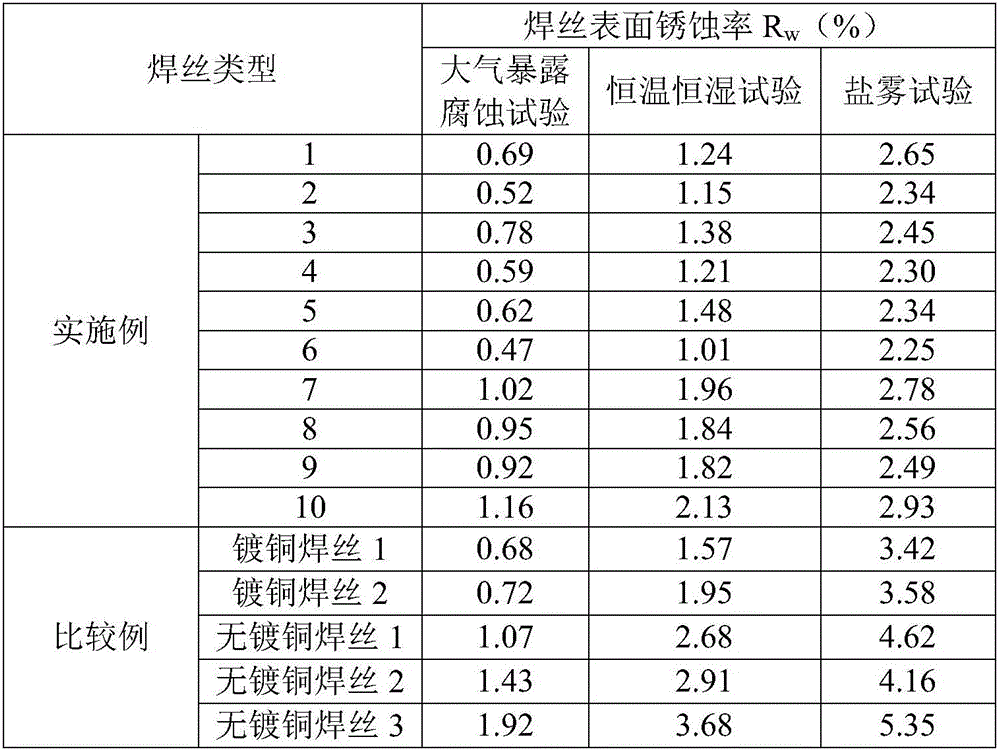

Examples

Embodiment 1

[0017] A nanocomposite coating on the surface of a copper-free solid welding wire is prepared by mechanical coating, wherein every 10kg of welding wire contains 0.5g of nanometer solid powder, 0.8g of antirust oil, and 1.2g of arc stabilizing agent.

[0018] The nanometer solid powder is mixed by the following substances by weight percentage: 10% nanoscale graphite fluoride powder, 15% nanoscale molybdenum powder, 3.0% nanometer molybdenum disulfide, 0.8% nanometer ferric oxide, 25% Micron-sized calcium fluoride or micron-sized barium fluoride, 46.2% micron-sized PTFE powder.

[0019] Anti-rust oil is made of the following ingredients by weight percentage: perfluoropolyether synthetic oil 80%, rapeseed oil 7%, sorbitan oleate 1.5%, sodium petroleum sulfonate 1.0%, lanolin 0.6%, nano Serpentine 2.0%, calcium naphthenate 0.5%, polyisobutylene bis-succinimide 3.0%, zinc dialkyldithiophosphate 2.2%, molybdenum dialkyldithiocarbamate 2.2%.

[0020] The arc stabilizer consists of s...

Embodiment 2

[0022] A nanocomposite coating on the surface of a non-copper-plated solid welding wire is prepared by mechanical coating, wherein every 10kg of welding wire contains 0.7g of nanometer solid powder, 0.3g of antirust oil, and 1.4g of arc stabilizing agent.

[0023] The nano solid powder is mixed by weight percentage: 12% nano-scale graphite fluoride powder, 14% nano-scale molybdenum powder, 5.0% nano-molybdenum disulfide, 2.2% nano-ferric oxide, 23% Micron-sized calcium fluoride, 43.8% micron-sized PTFE powder.

[0024] The anti-rust oil is made of the following ingredients by weight percentage: perfluoropolyether synthetic oil 77%, rapeseed oil 8%, sorbitan oleate 2.2%, sodium petroleum sulfonate 1.4%, lanolin 0.9%, nano Serpentine 2.2%, calcium naphthenate 0.9%, polyisobutylene bis-succinimide 3.5%, zinc dialkyldithiophosphate 2.5%, molybdenum dialkyldithiocarbamate 1.4%.

Embodiment 3

[0027] A nanocomposite coating on the surface of a copper-free solid welding wire is prepared by mechanical coating, wherein every 10kg of welding wire contains 0.9g of nanometer solid powder, 0.5g of antirust oil, and 1.2g of arc stabilizing agent.

[0028] Nano solid powder is mixed by weight percentage: 14% nano-scale graphite fluoride powder, 13% nano-scale molybdenum powder, 8% nano-tungsten disulfide, 1.4% nano-ferric oxide, 21% Micron-sized calcium fluoride, 42.6% micron-sized PTFE powder.

[0029] The anti-rust oil is made of the following ingredients by weight percentage: perfluoropolyether synthetic oil 75%, rapeseed oil 9%, sorbitan oleate 2.7%, sodium petroleum sulfonate 1.8%, lanolin 1.3%, nano Serpentine 2.5%, calcium naphthenate 0.7%, polyisobutylene bis-succinimide 3.2%, zinc dialkyldithiophosphate 2.3%, molybdenum dialkyldithiocarbamate 1.5%.

[0030] The arc stabilizer consists of cesium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com