Method for preparing chain shaped barium fluoride nanospheres with DNA as mould plate

A technology of barium fluoride and nanospheres, applied in the direction of titanium halide, etc., can solve the problems of uneven size distribution of nanospheres, irregular shape of barium fluoride, uneven particle size distribution, etc., and achieve excellent optical performance and regular shape. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to the mixed solution 5ml of water: ethanol volume ratio 1:3, prepare Ba(NO 3 ) 2 and NH 4 A supersaturated solution of F. DNA used: 0.38 μg / μL, OD: 1.76, 100 μL, pipetting repeatedly, thoroughly dispersed in water. Ba(NO 3 ) 2 The saturated solution was centrifuged, and 50 μL was added to the above DNA system, mixed evenly, vortexed for 3 minutes, placed at 20°C, and oscillated at 50 r / min for 2 hours. Mix the solution and quickly take the NH with a micropipette 4 Add 200 μL of solution F to the above system, vortex for 5 seconds, move to 20°C, and shake at 50 r / min for 3 hours. Finally, put the whole system in 4°C water and let it stand.

Embodiment 2

[0020] According to the mixed solution 5ml of water: ethanol volume ratio 1:4, prepare Ba(NO 3 ) 2 and NH 4 A supersaturated solution of F. DNA used: 0.62 μg / μL, OD: 1.87, 100 μL, pipetting repeatedly, thoroughly dispersed in water. Ba(NO 3 ) 2 The saturated solution was centrifuged, 100 μL was added to the above DNA system, mixed evenly, vortexed for 5 min, placed at 25°C, and oscillated at 100 r / min for 3 h. Mix the solution and quickly take the NH with a micropipette 4 Add 300 μL of solution F to the above system, vortex for 12 seconds, move to 25°C, and shake at 100 r / min for 4 hours. Finally, put the whole system in 6°C water and let it stand.

Embodiment 3

[0022] According to the mixed solution 5ml of water: ethanol volume ratio 1:5, prepare Ba(NO 3 ) 2 and NH 4 A supersaturated solution of F. DNA used: 1.30 μg / μL, OD: 1.87, 200 μL, pipetting repeatedly, thoroughly dispersed in water. Ba(NO 3 ) 2 The saturated solution was centrifuged, and 150 μL was added to the above DNA system, mixed evenly, vortexed for 8 minutes, placed at 30°C, and oscillated at 150 r / min for 4 hours. Mix the solution evenly, quickly use a micropipette to take 400 μL of NH4F solution and add it to the above system, vortex for 20 seconds, move to 30°C, and shake at 150 r / min for 5 hours. Finally, put the whole system in 8°C water and let it stand.

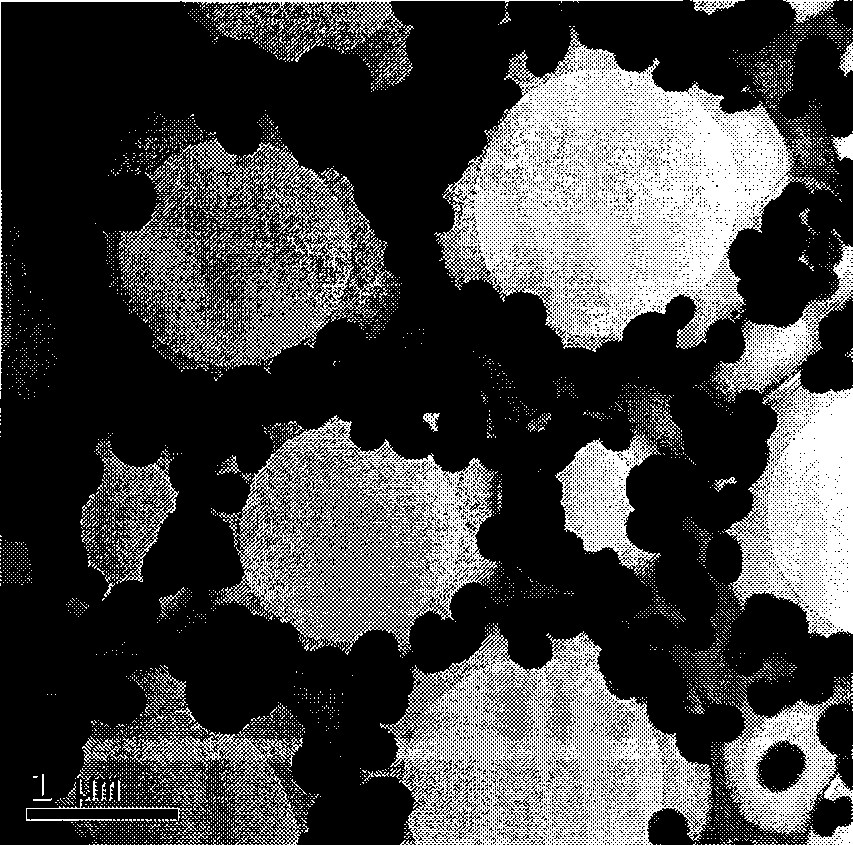

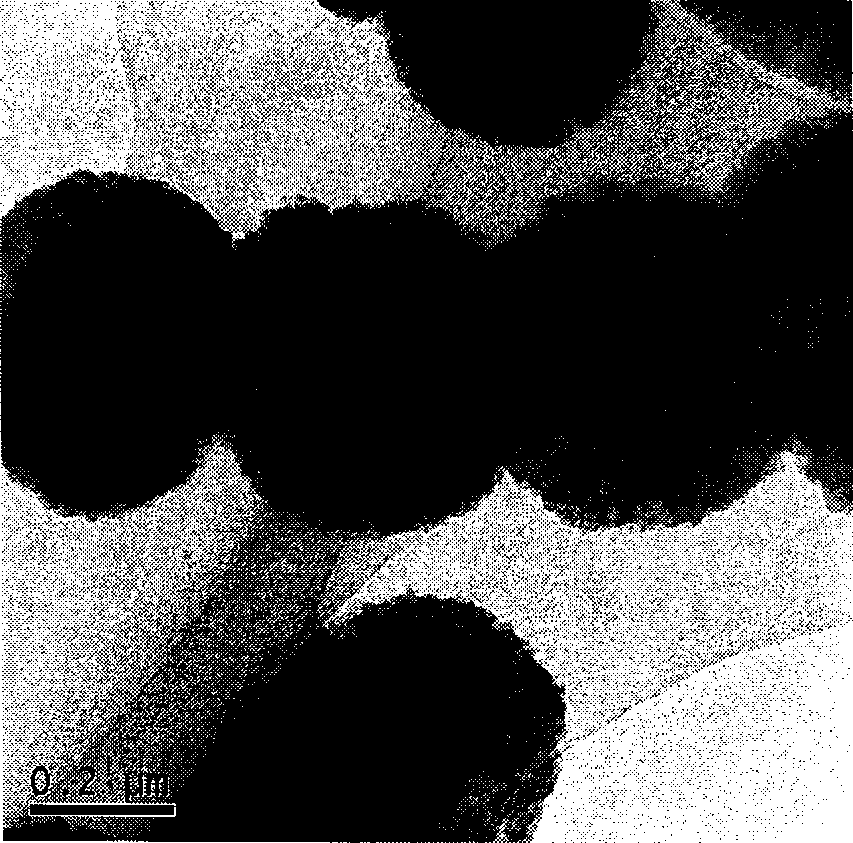

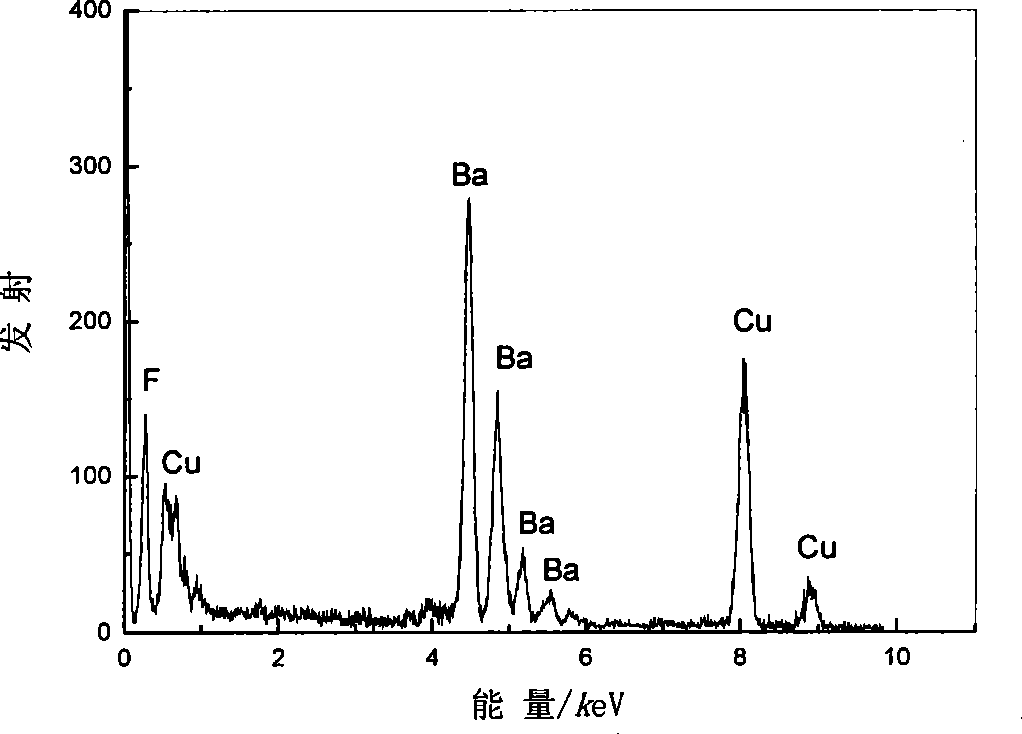

[0023] figure 1 It is a representative TEM image of chain-shaped barium fluoride nanosphere particles using DNA as a template. It can be seen from the figure that barium fluoride nanospheres are arranged in chains due to the structure induced by DNA, and the shape is better. Compared with the nanospheres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com