Preparation method of nanometer strontium ferrite magnetic powder

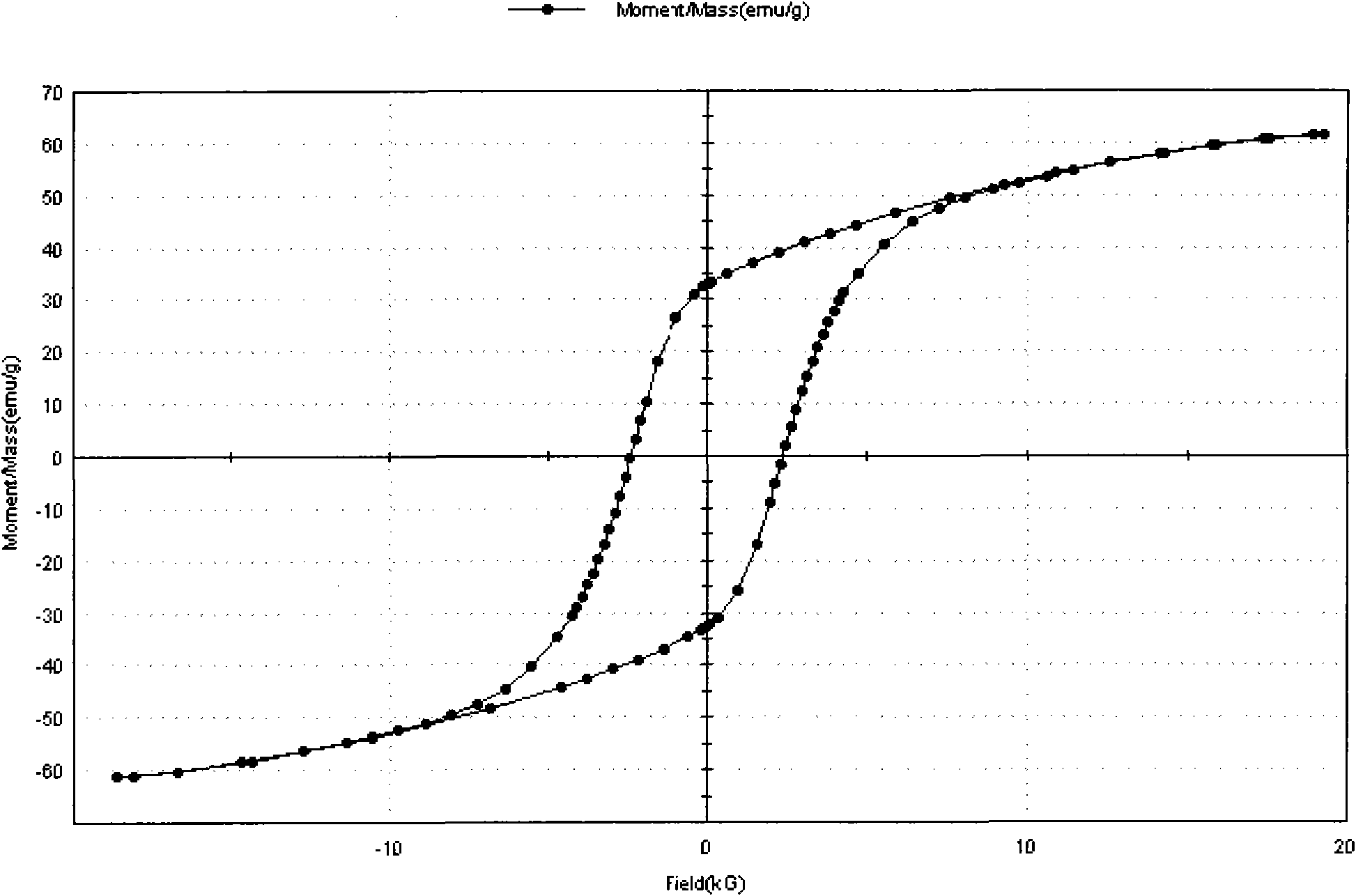

A ferrite magnet and nano-strontium technology, which is applied in the field of preparation of nano-strontium ferrite magnetic powder, achieves the effects of small product particle size, short reaction cycle and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

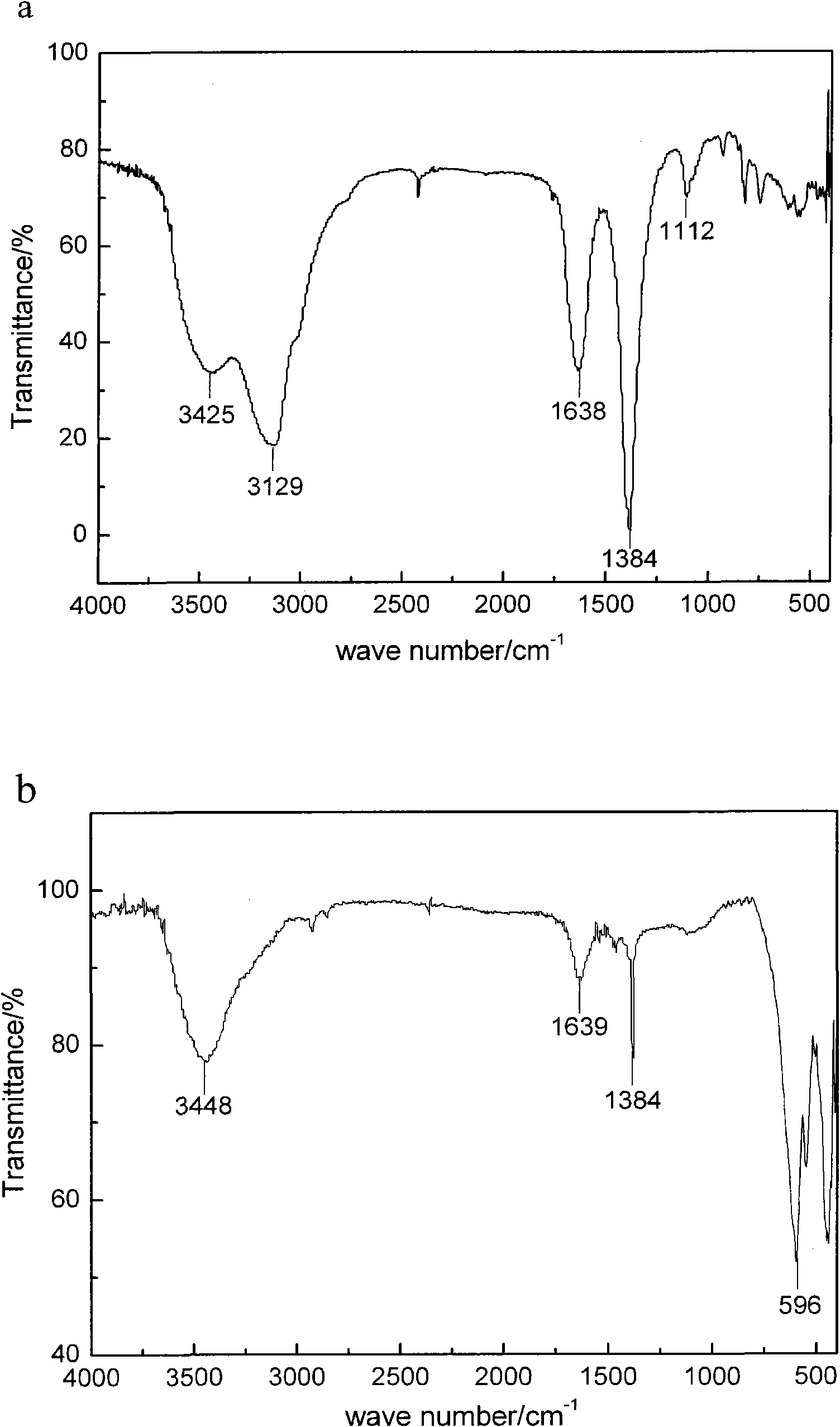

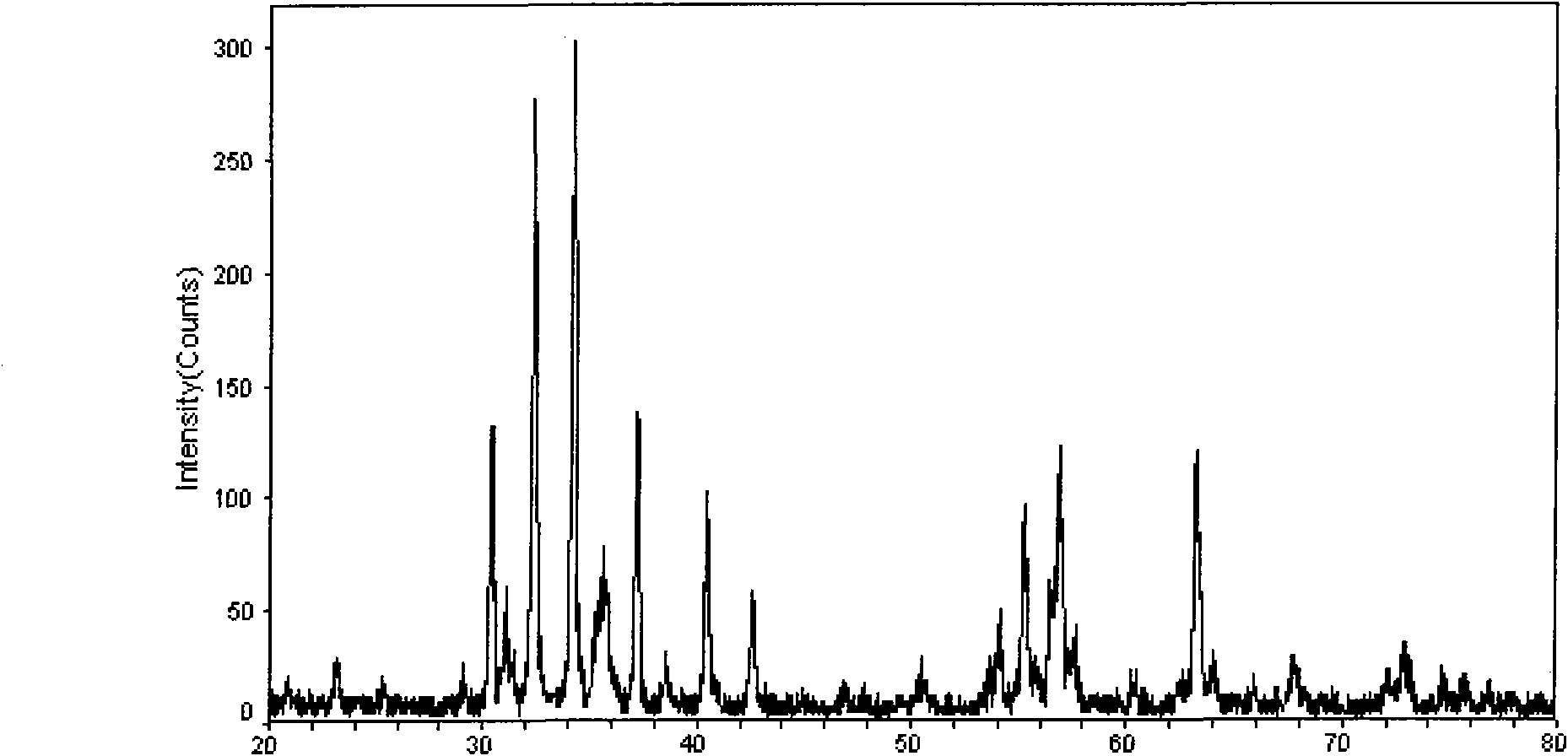

[0021] The preparation of embodiment 1 nanometer strontium ferrite magnetic powder

[0022] Take by weighing 20.1420g ferric nitrate crystal namely Fe(NO 3 ) 3 9H 2 O, dissolved in 50ml deionized water, weighed 0.6169g strontium carbonate (SrCO 3 ) add a small amount of nitric acid solution dropwise until completely dissolved, and mix and stir the strontium carbonate solution and ferric nitrate solution evenly. The molar ratio of Sr to Fe in the above mixed solution is 1:12. Dissolve 8.1327g of tartaric acid in the mixed solution, and then add 0.5601g of polyethylene glycol-2000 and stir to dissolve after it is completely dissolved. Then the pH value of the solution was adjusted to 7 with ammonia water to obtain a reddish-brown mixed solution. The reddish-brown mixed solution is first heated and stirred at 50°C to form a sol, then the temperature is raised to 70-80°C to form a gel from the sol, and then dried in an oven at 80-90°C for 24 hours to form a xerogel. Put the ...

Embodiment 2

[0023] The preparation of embodiment 2 nanometer strontium ferrite magnetic powder

[0024] Take by weighing 20.1965g ferric nitrate crystal namely Fe(NO 3 ) 3 9H 2 O was dissolved in 50ml deionized water, weighed 0.6151g strontium carbonate (SrCO 3 ) add a small amount of nitric acid solution dropwise until completely dissolved, and mix and stir the strontium carbonate solution and ferric nitrate solution evenly. The molar ratio of Sr to Fe in the above mixed solution is 1:12. Dissolve 8.1337g of tartaric acid in the mixed solution, and then add 0.6104g of polyethylene glycol-2000 and stir to dissolve after it is completely dissolved. Then the pH value of the solution was adjusted to 7 with ammonia water to obtain a reddish-brown mixed solution. First heat and stir the reddish-brown mixture at 50°C to form a sol, then raise the temperature to 70-80°C to make the sol form a gel, and then dry it in an oven at 80-90°C for 24 hours to form a xerogel. Put the dry gel into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com