Wear-resistant antifouling glazed brick glaze and preparation method thereof

A technology for polishing glazed tiles and glazes, which is applied in the field of architectural ceramics, can solve the problems of decreased transparency of glazes, reduced refractive index of glass phase, etc., so as to reduce scratches, enhance wear resistance, anti-skid effect, and wear resistance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

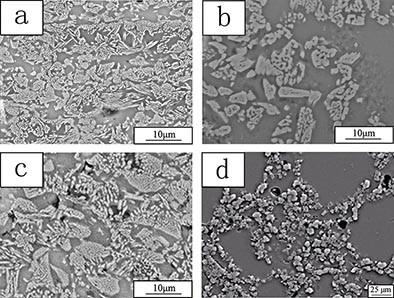

Image

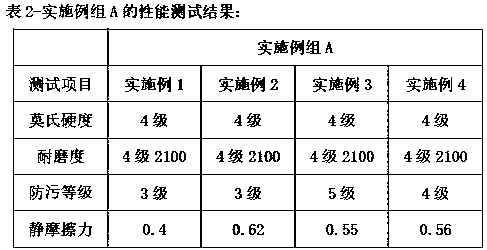

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below through specific embodiments.

[0035] The invention provides a wear-resistant and anti-fouling polished tile glaze, which comprises raw glaze powder, No. 1 frit powder and No. 2 frit powder;

[0036] The raw glaze powder includes the following raw materials in weight percentage: kaolin 8-12%, calcined kaolin 10-18%, quartz 12-20%, dolomite 12-20%, calcined talc 8-15%, wollastonite 1-5% %, nepheline 8-15%, zinc oxide 5-10%, calcite 0-5%, and strontium carbonate 6-12%;

[0037] The raw materials of the No. 1 frit powder include kaolin, calcined talc and fluorite, and the raw materials of the No. 2 frit powder include zinc oxide, strontium carbonate and borax.

[0038] Kaolin, calcined kaolin and calcined talc in the raw glaze powder are all suppliers of silicon, aluminum and magnesium elements in the cordierite crystal structure; in addition, kaolin and calcined kaolin also cooperate with w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| optical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com