Phenyl phosphonate with photocatalytic activity as well as preparation method and application thereof

A technology of phenylphosphonate and phenylphosphonic acid is applied in the field of photocatalytic materials to achieve the effects of easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

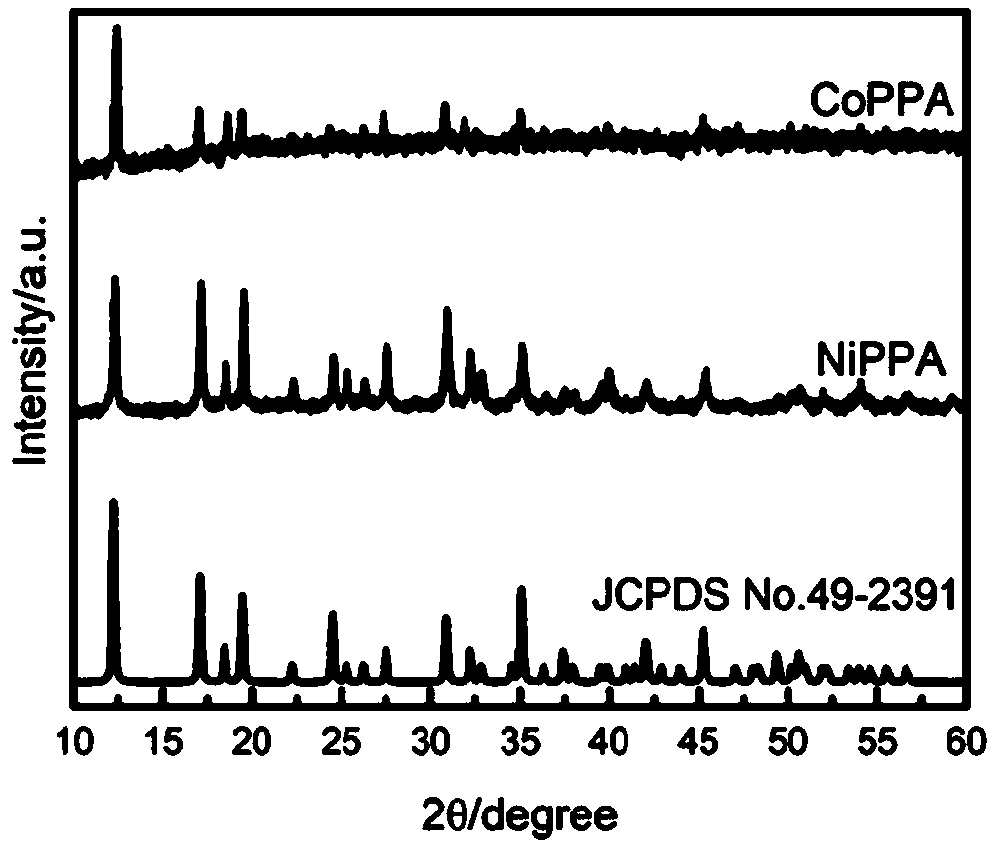

Embodiment 1

[0076] 1mmol of Co(NO 3 ) 2 ·6H 2 O and 1 mmol phenylphosphonic acid were added to 60 mL of N,N-dimethylformamide (DMF), stirred magnetically for 30 min at room temperature, transferred to a 100 mL polytetrafluoroethylene-lined reactor, and placed at 110 °C In a special oven, keep warm for 24 hours, cool down naturally, vacuum filter, wash three times with deionized water and alcohol alternately, and dry at 60°C for 12 hours to obtain a purple-red powder that is cobalt phenylphosphonate (CoPPA).

Embodiment 2

[0078] 1mmol of Ni(NO 3 ) 2 ·6H 2 O and 1 mmol phenylphosphonic acid were added to 60 mL of N,N-dimethylformamide (DMF), stirred magnetically for 30 min at room temperature, transferred to a 100 mL polytetrafluoroethylene-lined reactor, and placed at 110 °C In an oven, keep warm for 24 hours, cool down naturally, vacuum filter, wash 3 times alternately with deionized water and alcohol, and dry at 60°C for 12 hours to obtain a yellow-green powder that is nickel phenylphosphonate (NiPPA).

Embodiment 3

[0080] Get the cobalt phenylphosphonate (CoPPA) sample that 50mg embodiment 1 prepares and the nickel phenylphosphonate (NiPPA) sample that embodiment 2 prepares and add respectively to two 99mL deionized water and 1mL triethanolamine (TEOA) are housed In the reactor, ultrasonic 10min, put the two reactors into the photocatalytic hydrogen production reaction system, pass the cooling circulating water, maintain the system temperature at 15 ℃, vacuumize, and then add 254nm ultraviolet lamp to irradiate, set the chromatographic sampling time to 1h .

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com