Alkaloid phosphate flame retardant and preparation method thereof

A technology of alkaloid phosphate and flame retardant, which is applied in the field of polymer materials to achieve the effect of improving flame retardant efficiency and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-1

[0039] Into a 100 mL three-necked round bottom flask equipped with a spherical condenser, magnetic heating and stirring, a thermometer and a dropping funnel, add ethanol (30 mL, water removed), and cytosine (2.22 g, 0.02 mol). Stir and warm to 60°C under nitrogen. Weigh pyrophosphoric acid (1.78g, 0.01mol) into a beaker, add ethanol (20mL, water removed) and stir until completely dissolved, then slowly drop it into a three-neck flask through a dropping funnel and stir for 6h. The reaction solution was cooled at room temperature, washed three times with absolute ethanol, filtered and vacuum-dried to obtain 3.84g white solid product 1 (yield rate:

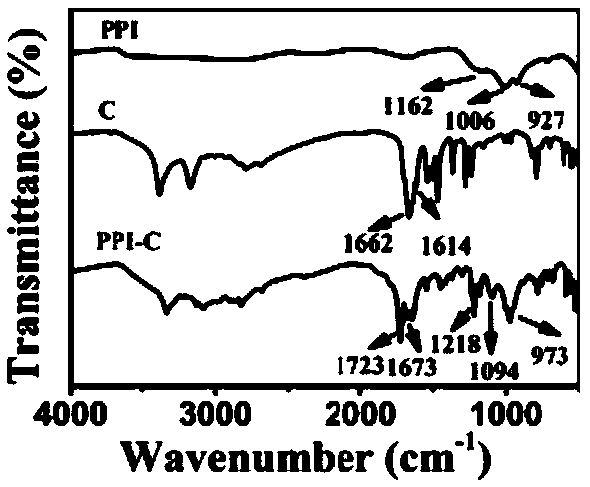

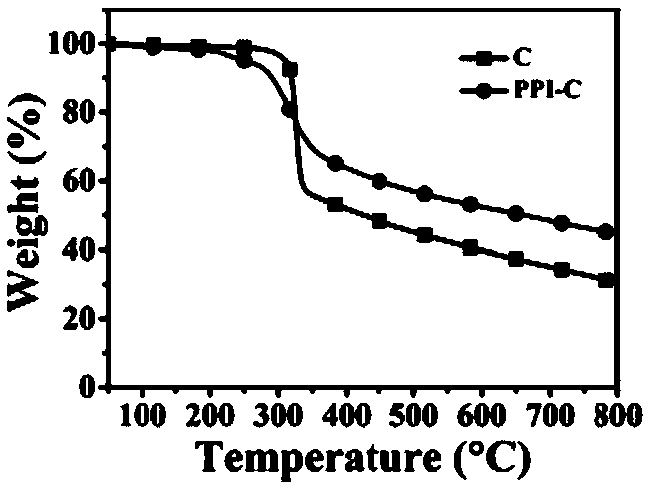

[0040] Y%=96.0%), the product structure is shown in formula 1. figure 1 It is the infrared spectrogram of embodiment 1-1 product. figure 2 It is the thermogravimetric curve of the product of Example 1-1.

[0041]

example 1-2

[0043] Into a 500 mL three-necked round bottom flask equipped with a spherical condenser, magnetic heating and stirring, a thermometer and a dropping funnel, add methanol (200 mL, water removed), and cytosine (22.22 g, 0.20 mol). Stir and warm to 60°C under nitrogen. Weigh pyrophosphoric acid (8.90 g, 0.05 mol) into a beaker, add methanol (50 mL, water removed) and stir until completely dissolved, then slowly drop it into a three-necked flask through a dropping funnel and stir for 4 h. The reaction solution was cooled at room temperature, washed three times with absolute ethanol, filtered and vacuum-dried to obtain 29.56 g of white solid product 2 (yield: Y%=95.0%), the product structure is shown in formula 2.

[0044]

example 1-3

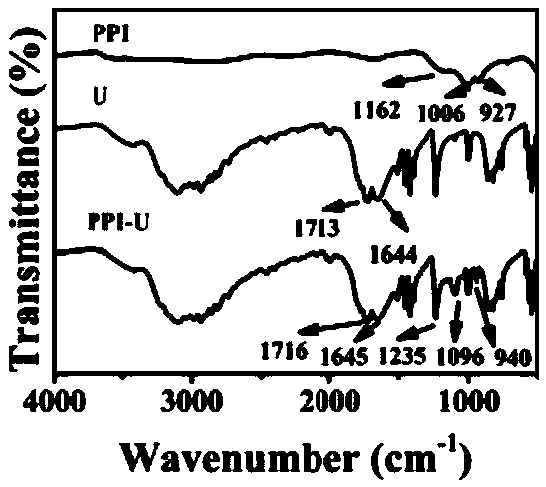

[0046] In a 250 mL three-neck round bottom flask equipped with a spherical condenser, magnetic heating and stirring, a thermometer and a dropping funnel, add acetonitrile (100 mL, water removed), and uracil (11.2 g, 0.1 mol). Stir and warm to 90°C under nitrogen. Weigh pyrophosphoric acid (8.90 g, 0.05 mol) into a beaker, add acetonitrile (20 mL, water removed) and stir until completely dissolved, then slowly drop it into a three-neck flask through a dropping funnel and stir for 8 h. The reaction solution was cooled at room temperature, washed three times with absolute ethanol, filtered and vacuum-dried to obtain 18.24 g of white solid product 3 (yield: Y%=90.7%), the product structure is shown in formula 3. image 3 Be the infrared spectrogram of embodiment 1-3 product; Figure 4 It is the thermogravimetric curve of embodiment 1-3 product.

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com