Preparation method of cluster MnO2, secondary zinc-manganese battery positive electrode material and secondary zinc-manganese battery

A zinc-manganese battery and cluster technology, applied in secondary batteries, battery electrodes, manganese oxide/manganese hydroxide, etc., can solve the problem of reducing the utilization rate of active materials and the electrochemical activity of electrodes, limiting large-scale market applications, and recycling Poor stability and other issues, to achieve the effect of improving conductivity and electrochemical activity, enhancing electrode reversibility, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh MnSO in a molar ratio of 1:1 4 ·H 2 O and (NH 4 ) 2 S 2 O 8 Dissolved in deionized water, adding phenylphosphonic acid as an additive to make it compatible with MnSO 4 ·H 2 The O molar ratio was 0.04. Dilute to 250mL to make MnSO 4 ·H 2 O and (NH 4 ) 2 S 2 O 8 The concentration is 0.05mol / L, and the concentration of phenylphosphonic acid is 0.002mol / L; a homogeneous solution is obtained;

[0033] (2) transfer the obtained homogeneous solution into a hydrothermal kettle, put it into a muffle furnace to carry out a hydrothermal process, and the reaction conditions are 110° C. for 16 h to obtain a gray-black suspension;

[0034] (3) The gray-black suspension was filtered by suction, washed with deionized water, and then the precipitate was vacuum-dried at 60 °C for 24 h to obtain the micro-nano-clustered manganese dioxide material.

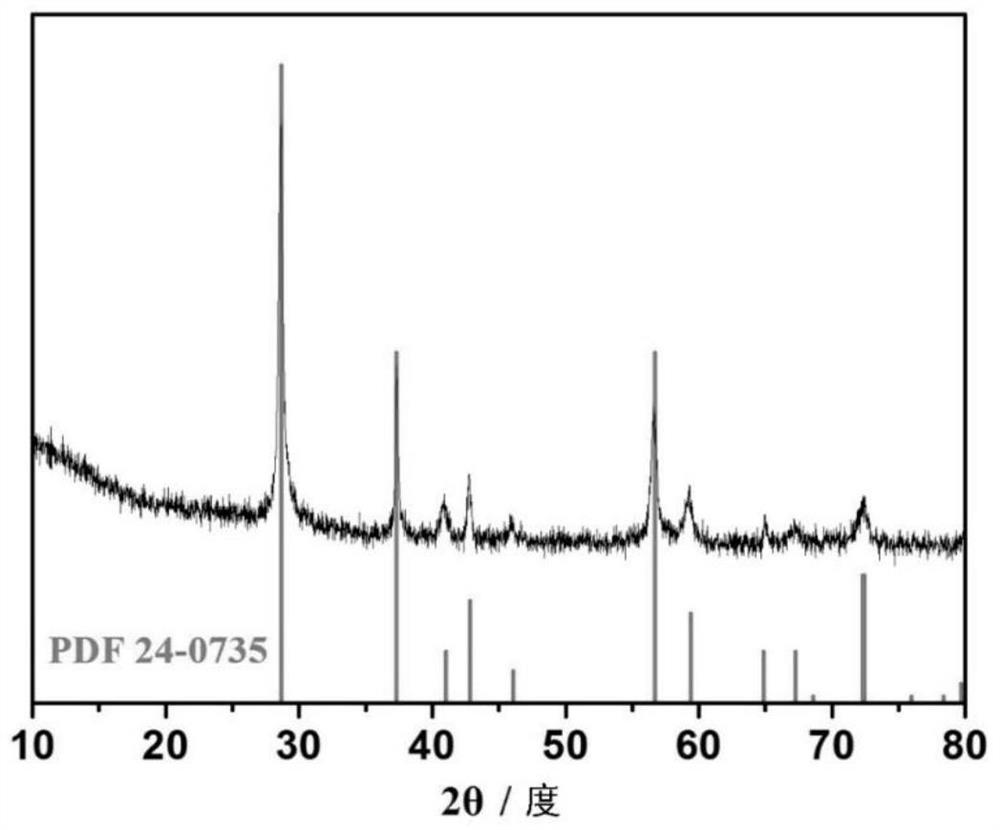

[0035] like figure 1 As shown, the material obtained by XRD characterization is β-type manganese dioxide, and its di...

Embodiment 2

[0037] (1) Weigh MnSO in a molar ratio of 1:1 4 ·H 2 O and (NH 4 ) 2 S 2 O 8 Dissolved in deionized water, disodium phenylphosphonate dihydrate was added as an additive to make it compatible with MnSO 4 ·H 2 The O molar ratio was 0.12. Dilute to 250mL to make MnSO 4 ·H 2 O and (NH 4 )2 S 2 O 8 The concentrations are all 0.1 mol / L, and the concentration of disodium phenylphosphonate is 0.012 mol / L; a homogeneous solution is obtained;

[0038] (2) transfer the obtained homogeneous solution to a hydrothermal kettle, put it into a muffle furnace to carry out a hydrothermal process, and the reaction conditions are 130° C. for 6 h to obtain a gray-black suspension;

[0039] (3) The gray-black suspension was filtered by suction, washed with deionized water, and then the precipitate was vacuum-dried at 90° C. for 12 h to obtain the micro-nano-clustered manganese dioxide material.

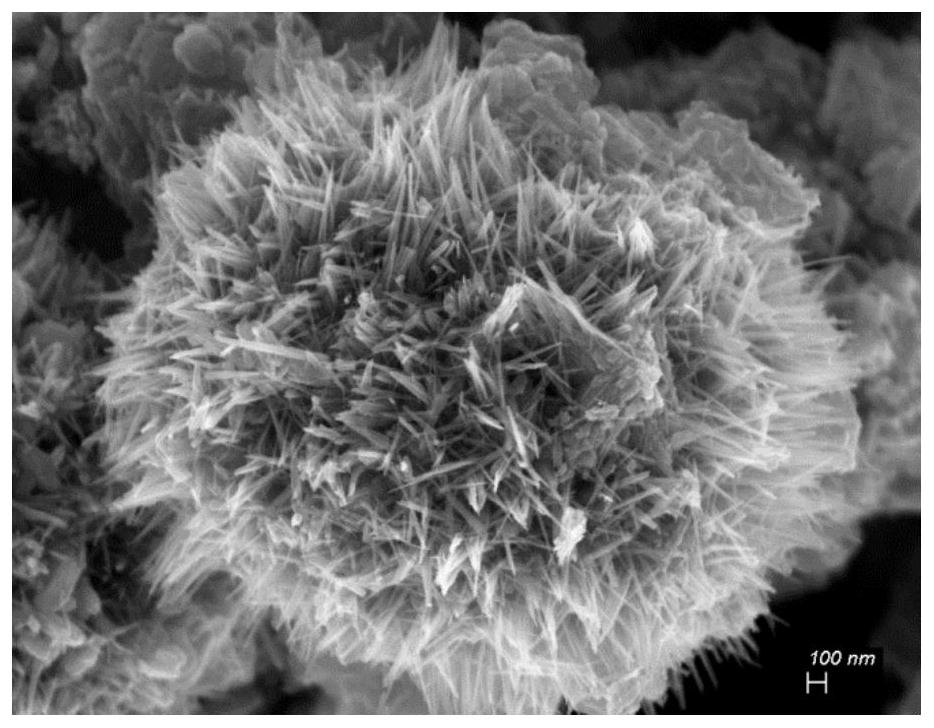

[0040] like image 3 As shown, the SEM characterization shows that the material is organic...

Embodiment 3

[0042] (1) Weigh MnSO in a molar ratio of 1:1 4 ·H 2 O and (NH 4 ) 2 S 2 O 8 Dissolved in deionized water, disodium phenylphosphonate dihydrate was added as an additive to make it compatible with MnSO 4 ·H 2 The O molar ratio is 0.1. Dilute to 250mL to make MnSO 4 ·H 2 O and (NH 4 ) 2 S 2 O 8 The concentrations are all 0.07mol / L, and the concentration of disodium phenylphosphonate is 0.007mol / L; a homogeneous solution is obtained;

[0043] (2) transfer the obtained homogeneous solution into a hydrothermal kettle, put it into a muffle furnace to carry out a hydrothermal process, and the reaction conditions are 120° C. for 12 h to obtain a gray-black suspension;

[0044] (3) The gray-black suspension was filtered by suction, washed with deionized water, and then the precipitate was vacuum-dried at 90° C. for 12 h to obtain the micro-nano-clustered manganese dioxide material.

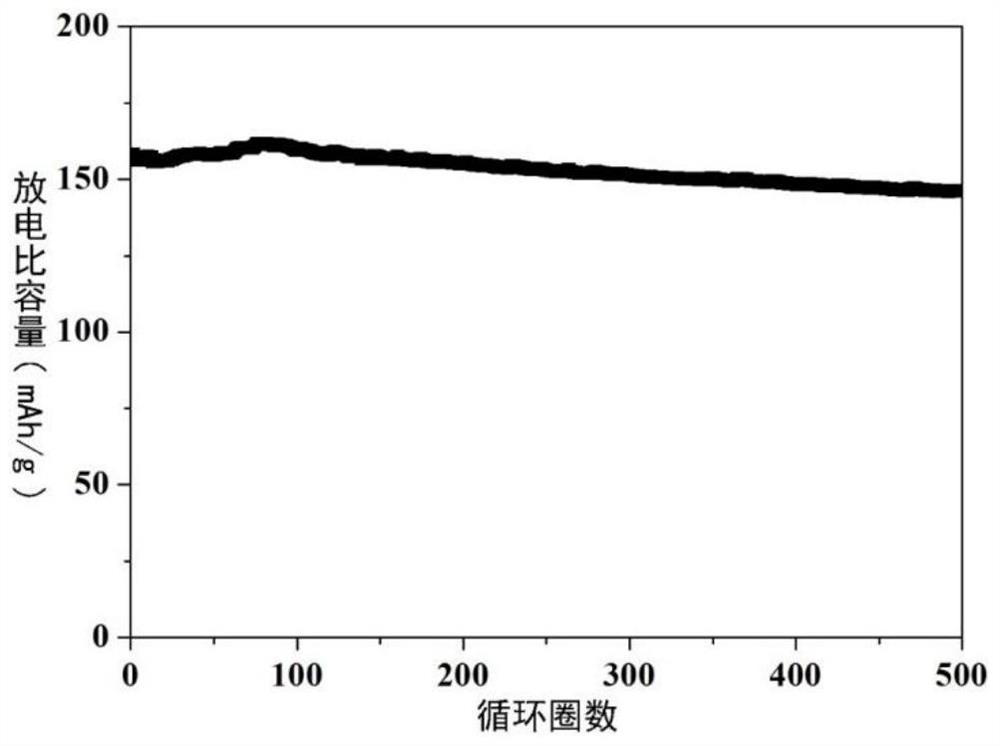

[0045] The micro-nano-clustered manganese dioxide material was used as the positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com