Device and method for preparing large-diameter palladium powder

A large particle size, palladium powder technology, applied in the field of large particle size palladium powder preparation technology, can solve the problems of flying loss, water absorption, oxidation, etc., and achieve the effect of high compaction density, not easy to oxidize, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

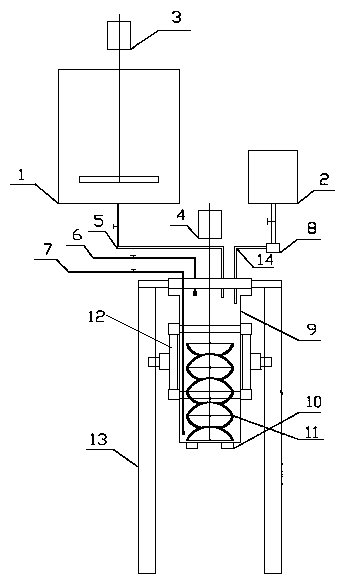

[0030] like figure 1 As shown, a device for preparing palladium powder with a large particle size includes a palladium solution storage tank 1, a reducing agent storage tank 2, a palladium solution catheter 5, a negative pressure suction pipe 7, a reaction kettle 9, and a reaction kettle lifting mechanism 10 , fixed frame 13, reductant catheter 14, reactor 9 is installed on the suspension frame 12 by the reactor elevating mechanism 10, and the suspension frame 12 both sides are installed on the fixed frame 13 through the rotating shaft, and the reactor 9 top passes through The fastening mechanism is connected with the lid of the kettle, and the lid of the kettle is fixedly arranged on the top of the fixed frame 13. The top of the lid of the kettle is connected with the liquid outlet at the bottom of the palladium solution storage tank 1 through the palladium solution catheter 5, and the palladium solution catheter 5 is provided with Valve, the top of the kettle cover is connec...

Embodiment 2

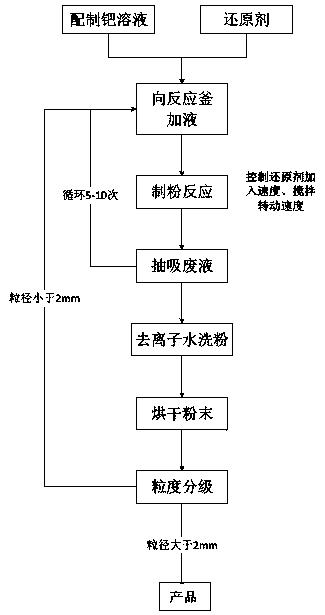

[0041] like figure 2 Shown, a kind of use method of the device that prepares large particle diameter palladium powder, comprises the steps:

[0042] Step 1: in palladium solution storage tank 1, add by Pd (NH 3 ) 2 Cl 2 with NH 3 ·H 2 The palladium complex Pd(NH 3 ) 4 Cl 2 At the same time, deionized water was added to make the palladium concentration of the solution reach 100g / L. During the operation, the reactant was heated to 80 degrees Celsius through a flexible heating mantle to speed up the reaction process;

[0043] Step 2: Filling the reducing agent storage tank 2 with a liquid reducing agent;

[0044] Step 3: open the valve on the palladium solution catheter 5 to allow the palladium solution to flow into the reactor 9 through the palladium solution catheter 5, and close the valve when the palladium solution liquid level reaches 5L;

[0045] Step 4: Open the valve on the reducing agent catheter 14, and control the speed of adding the reducing agent into the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com