Preparation method and application of nitrogen-doped activated carbon fibrofelt

An activated carbon fiber felt, nitrogen-doped technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of high cost, complicated preparation method, unsuitable for large-scale industrial production, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

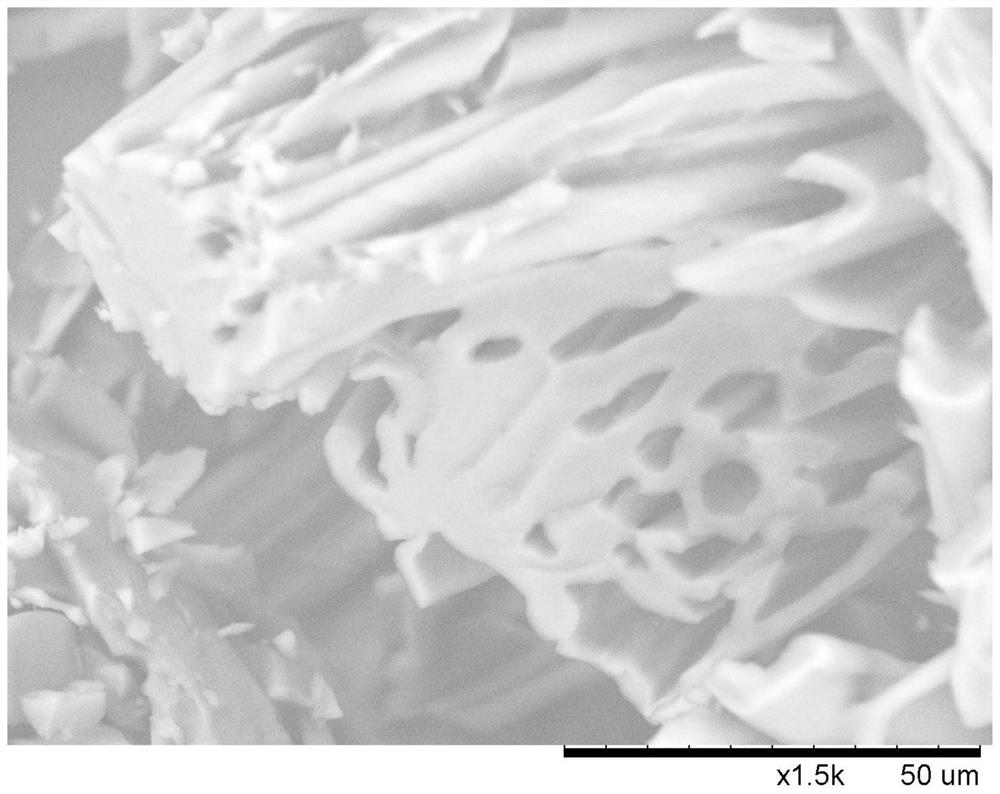

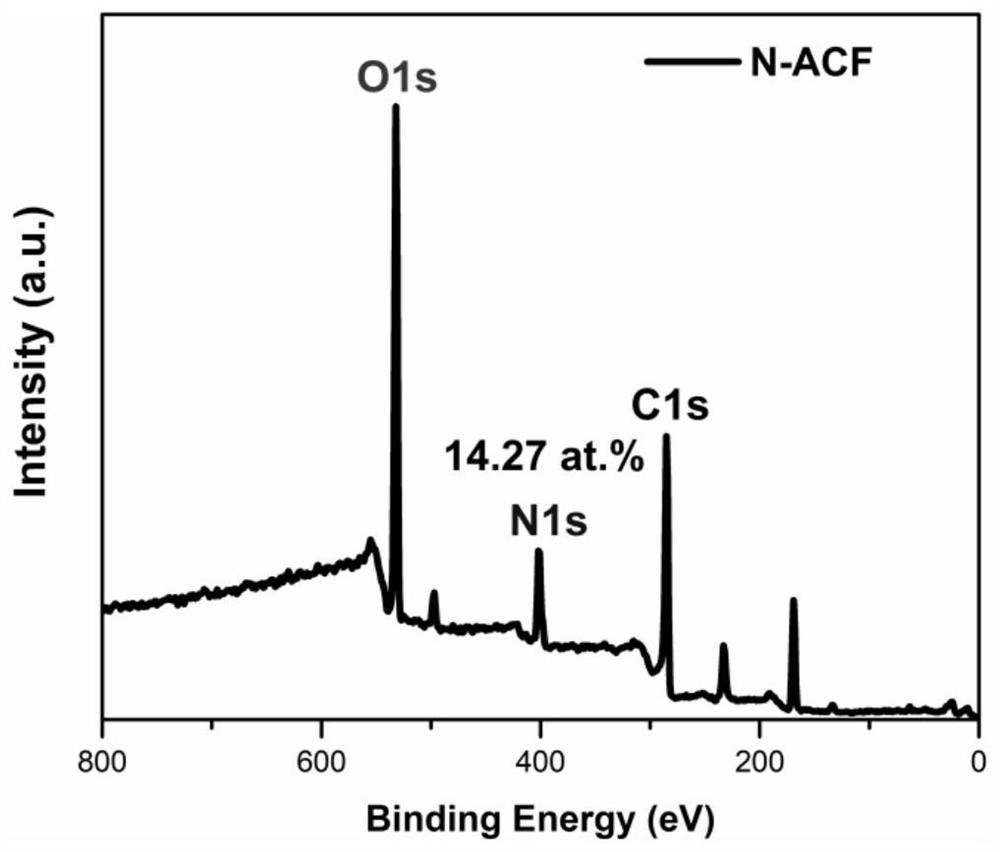

Image

Examples

Embodiment 1

[0037] (1) Take the BET specific surface area as 1300m 2 / g raw material viscose fiber mat 4.0011g, soak in 400mL solution containing urea (18.4g) and formaldehyde (37% formaldehyde, 25mL) molar ratio 1:3, add 18.4mL 1M formic acid solution, react for 90min;

[0038] (2) Put the product in 250mL of 2M hydrochloric acid solution, solidify for 30min, take it out, wash with water, and dry at 105°C for 1h;

[0039] (3) Put it into a muffle furnace, protect it with nitrogen at a flow rate of 25mL / min, carbonize at 400°C, heat up at a rate of 5°C / min, keep it warm for 1h, keep the nitrogen atmosphere until the furnace temperature drops to room temperature, and take out the product;

[0040] (4) Put the product into 250mL carbon residue cleaning solution, the mass ratio of carbon residue cleaning solution is alcohol ether surfactant (AEO-9), solvent oil, ethanolamine and water 10:1:1:88, at room temperature After ultrasonic cleaning for 30 minutes, fully wash with water, and dry at ...

Embodiment 2

[0043] (1) Take the BET specific surface area as 1500m 2 / g 5.0021g of raw viscose fiber felt, soaked in 500mL solution containing urea (23.0g) and formaldehyde (37% formaldehyde, 21mL) with a molar ratio of 1:2, added 22.8mL of 1M formic acid solution, and reacted for 90min;

[0044] (2) Put the product in 250mL of 2M hydrochloric acid solution, solidify for 30min, take it out, wash with water, and dry at 105°C for 1h;

[0045] (3) Put in a muffle furnace, protect with nitrogen at a flow rate of 25mL / min, carbonize at 600°C, heat up at a rate of 5°C / min, keep warm for 1h, keep the nitrogen atmosphere until the furnace temperature drops to room temperature, and take out the product;

[0046] (4) Put the product into 250mL carbon residue cleaning solution, the mass ratio of carbon residue cleaning solution is alcohol ether surfactant (AEO-9), solvent oil, ethanolamine and water 10:1:1:88, at room temperature After ultrasonic cleaning for 30 minutes, fully wash with water, and ...

Embodiment 3

[0049] (1) Take the BET specific surface area as 1800m 2 / g raw material viscose fiber felt 3.5007g, soak in 350mL solution containing urea (18.0g) and formaldehyde (37% formaldehyde, 24.5mL) molar ratio 1:3, add 18mL 1M formic acid solution, react for 90min;

[0050] (2) Put the product in 250mL of 2M hydrochloric acid solution, solidify for 30min, take it out, wash with water, and dry at 105°C for 1h;

[0051] (3) Put it into a muffle furnace, protect it with nitrogen at a flow rate of 25mL / min, carbonize at 800°C, heat up at a rate of 5°C / min, keep it warm for 1h, keep the nitrogen atmosphere until the furnace temperature drops to room temperature, and take out the product;

[0052] (4) Put the product into 250mL carbon residue cleaning solution, the mass ratio of carbon residue cleaning solution is alcohol ether surfactant (AEO-9), solvent oil, ethanolamine and water 10:1:1:88, at room temperature After ultrasonic cleaning for 30 minutes, fully wash with water, and dry at...

PUM

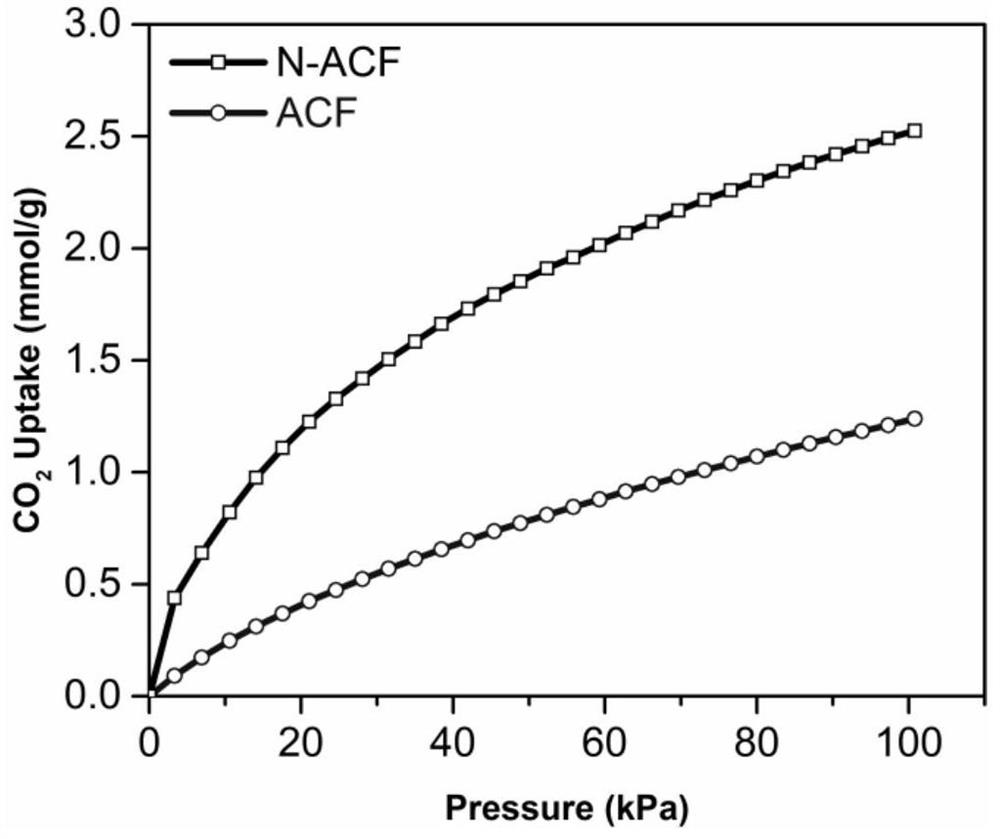

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com