Preparation method of MXene reinforced resin-based composite material

A technology for reinforcing resin-based and composite materials, applied in the field of material science, can solve problems such as poor environmental protection, difficult operation, and cumbersome steps, and achieve the effects of improving mechanical properties, avoiding agglomeration effects, and high specific surface area characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

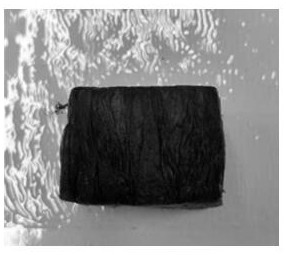

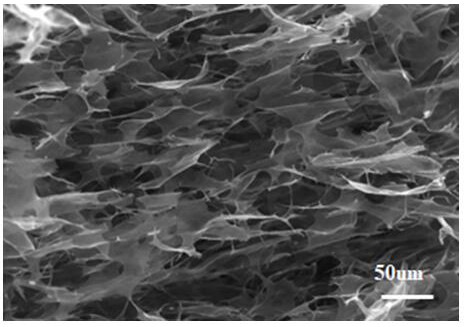

[0040] The invention provides a preparation method of an MXene sponge reinforced resin-based composite material, which comprises the following steps:

[0041] 1. Etching of titanium aluminum carbide:

[0042] The MXene was prepared by a modified in-situ hydrofluoric acid-etching titanium-aluminum carbide method to avoid the danger of directly using hydrofluoric acid. Take Ti with a mass ratio of 1:1.6~2 3 AlC 2 and lithium fluoride, adding lithium fluoride to 9mol / L hydrochloric acid, of which: 1g Ti 3 AlC 2 Corresponding to 20ml of concentrated hydrochloric acid, lithium fluoride was stirred in hydrochloric acid for at least 20min. After fully stirring the hydrochloric acid and lithium fluoride, slowly add titanium aluminum carbide to the mixed solution and continue magnetic stirring, wherein: the time for adding 1g titanium aluminum carbide should be 10~15min, the speed of magnetic stirring is controlled at 15r / min, and the mixing Changes in temperature and the violent ...

Embodiment 1

[0053] 1. Etching of titanium aluminum carbide:

[0054] MXene was prepared by etching titanium aluminum carbide with hydrofluoric acid. Take 2g Ti 3 AlC 2 and 3.2g lithium fluoride, add lithium fluoride to 40ml of 9mol / L hydrochloric acid. After the hydrochloric acid and lithium fluoride are fully stirred, titanium aluminum carbide is slowly added to the mixed solution and stirred, and the temperature change and the violent generation of bubbles are avoided during the mixing process. After adding all the titanium aluminum carbide, the mixed solution was etched at 35°C for 36 hours.

[0055] 2. Collection of MXene:

[0056] The solution obtained in step 1 was put into a centrifuge tube and washed with deionized water until the pH value of the solution was about 7. The cleaning process was 3500 rpm, 5 min, and deionized water was continued to be added after the supernatant was poured out. The pellet was layered by vortexing for 60 min. Then put it into a blue-capped bott...

Embodiment 2

[0066] 1. Etching of titanium aluminum carbide:

[0067] MXene was prepared by etching titanium aluminum carbide with hydrofluoric acid. Take 2g Ti 3 AlC 2 and 3.2g lithium fluoride, add lithium fluoride to 40ml of 9mol / L hydrochloric acid. After the hydrochloric acid and lithium fluoride are fully stirred, titanium aluminum carbide is slowly added to the mixed solution and stirred, and the temperature change and the violent generation of bubbles are avoided during the mixing process. After adding all the titanium aluminum carbide, the mixed solution was etched at 50°C for 48 hours.

[0068] 2. Collection of MXene:

[0069] The solution obtained in step 1 was put into a centrifuge tube and washed with deionized water until the pH value of the solution was about 7. The cleaning process was 3500 rpm, 5 min, and deionized water was continued to be added after the supernatant was poured out. Shake well for 60 min by vortex shaker to make the precipitate evenly and stably dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com