Preparation method and application of a hollow core-shell structure metal-organic framework material

An organic framework and shell structure technology, applied in the field of materials, can solve the problems of long time, complicated preparation process, and harsh template removal processing conditions, and achieve the effect of simple preparation process, stable precious metal nanoparticles, and synergistically enhancing high-efficiency catalysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

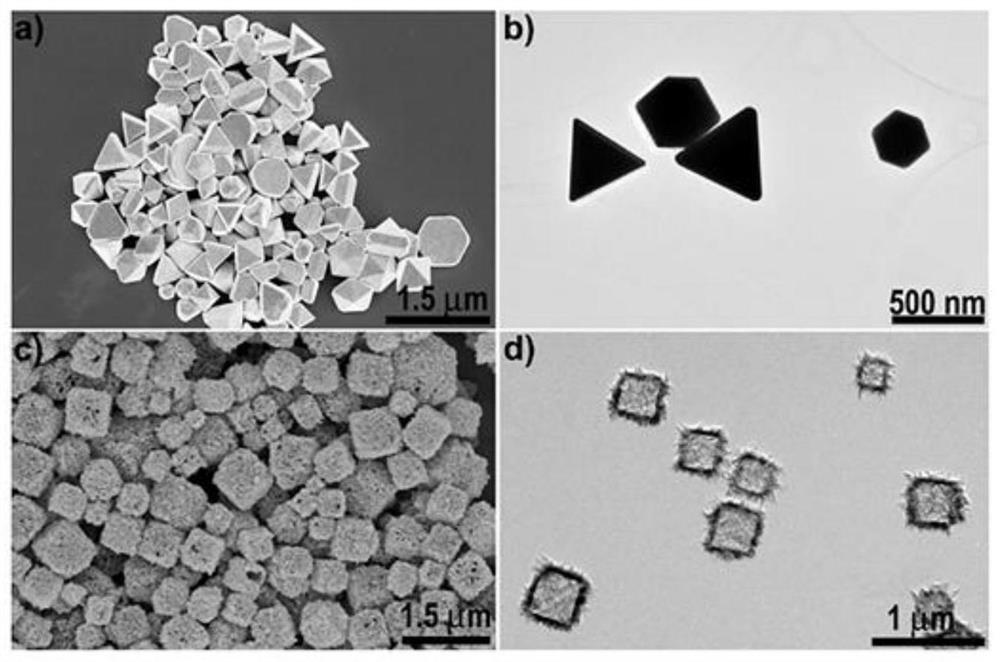

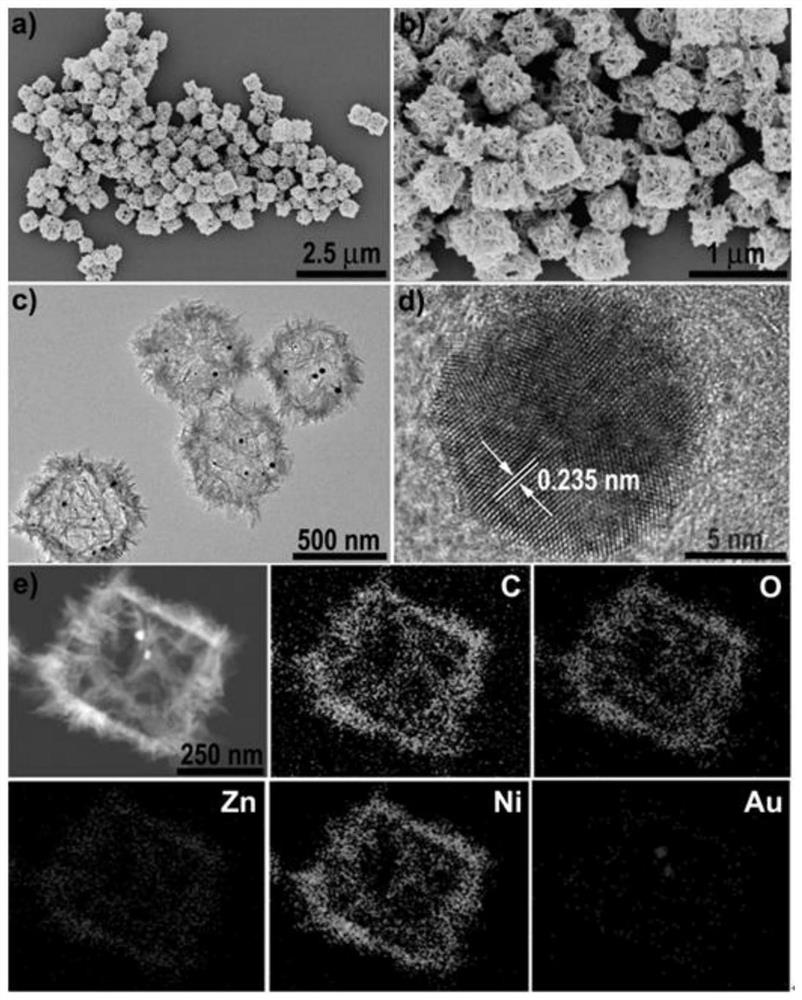

[0047] Example 1: One-step preparation of hollow core-shell functional materials (Au@Zn / Ni-MOF-2 nanocubes)

[0048] Weigh 25 mg of zinc nitrate hexahydrate, 37 mg of nickel acetylacetonate, 12 mg of terephthalic acid and 1.36 g of PVP and dissolve in 25.6 mL of DMF-DMAC-EtOH (volume ratio=5:5:6). After fully dissolved, add 400 μL HAuCl with stirring 4 4H 2 O (0.02g mL -1 ), the resulting mixture was transferred to a 50 mL autoclave, and reacted at 150 °C for 4 h. Cool to room temperature, centrifuge at 10,000 rpm for 5 minutes to collect the product, wash with ethanol, and dry overnight at 70° C. under vacuum.

[0049] pass figure 2 The morphology and microstructure of the hollow core-shell structured Au@Zn / Ni-MOF-2 can be clearly revealed, which has a well-defined cubic structure with a size of about 500 nm, a very rough surface, and consists of a large number of nanosheets. It can be clearly seen that there is a hollow structure in each core-shell nanocube structure, ...

Embodiment 2

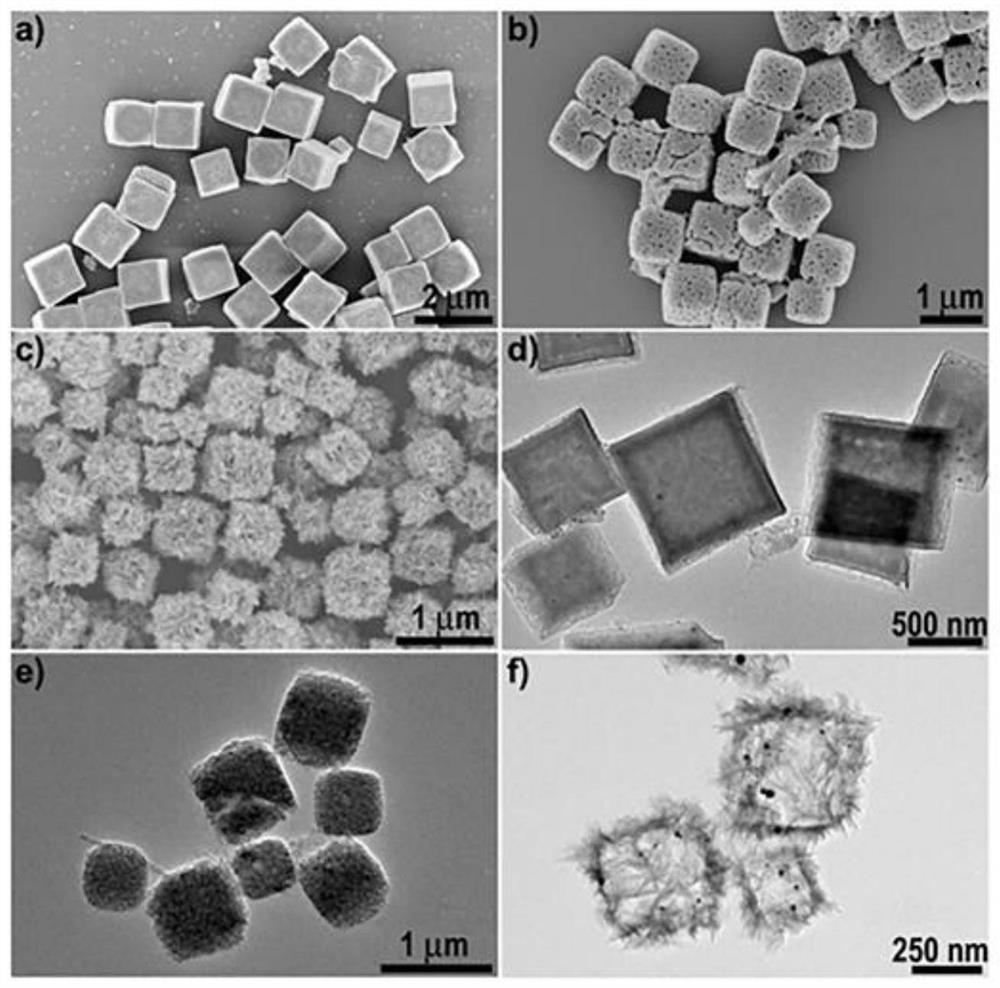

[0058] Example 2: One-step preparation of a hollow core-shell functional material (AgPd@Zn / Ni-MOF-2 nanocube)

[0059] Weigh 25 mg of zinc nitrate hexahydrate, 37 mg of nickel acetylacetonate, 12 mg of terephthalic acid, 1.36 g of PVP, and 1.44 mg of silver nitrate and dissolve in 25.6 mL of DMF-DMAC-EtOH (volume ratio=5:5:6). After fully dissolved, add 75 μL PdCl under stirring 2 solution, the resulting mixture was transferred to a 50 mL stainless steel autoclave, and reacted at 150 °C for 4 h. Cool to room temperature, centrifuge at 10,000 rpm for 5 minutes to collect the product, wash with ethanol, and dry overnight at 70° C. under vacuum.

[0060] pass Figure 7 The morphology and microstructure of the hollow core-shell structure AgPd@Zn / Ni-MOF-2 can be clearly revealed, with a clear cubic structure and each cavity with a size of 500nm, and it is obvious that the cavity contains AgPd alloy nanoparticles.

Embodiment 3

[0061] Example 3: Application of Hollow Core-Shell Structured Functional Materials in Catalytic Alcohol Oxidation Reaction

[0062] In the alcohol catalytic oxidation reaction, the catalytic oxidation of benzyl alcohol to benzaldehyde was first selected to test the efficiency of the hollow core-shell structure catalyst synthesized in implementation 1. Into a 50 mL round bottom flask was added 15 mg of the material synthesized in Example 1 dissolved in 6 mL of toluene solution, followed by the addition of 0.2 mmol of benzyl alcohol. The reaction mixture was stirred at 95°C for the required time. After the reaction, the catalyst particles in the solution were recovered by centrifugation. Conversion and selectivity were determined by GC and characterized by GC-MS.

[0063] For the recyclability test, the catalyst was recovered from the solution by centrifugation, washed with ethanol, dried at 70 °C, and then subjected to the next cycle of catalysis under the same reaction condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com