Cobalt-nickel bimetal phosphate flower-like microsphere electrocatalyst and preparation method thereof

A phosphate flower and bimetallic technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve problems such as large overpotential, limited oxygen evolution electrocatalysis, slow kinetics, etc., and achieve structural stability , increase the transfer channel, the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

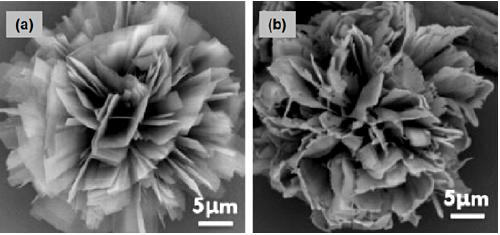

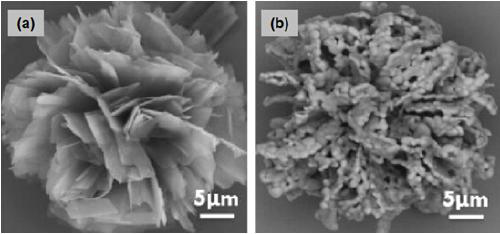

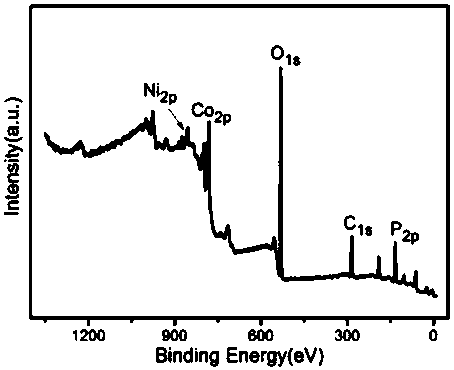

[0022] 1. Synthesis of cobalt-nickel bimetallic organic phosphonic acid compound microsphere precursor: weigh 2.0 mmol of phenylphosphonic acid with an electronic balance, add it to 50 ml of deionized water, and prepare phenylphosphonic acid with a concentration of 0.04 mol / L Aqueous solution, called solution A; cobalt nitrate hexahydrate (Co(NO 3 ) 2 •6H 2 O) and nickel nitrate hexahydrate (Ni(NO 3 ) 2 •6H 2 O) Weigh 2.0 mmol according to the molar ratio of 8:2, and add it into 50 ml deionized water to form a solution with a concentration of 0.04 mol / L, which is called solution B. Mix the two solutions A and B, stir evenly on a magnetic stirrer, then add 0.20 mol of urea, stir evenly after 30 min, transfer the mixture to a Teflon reactor, heat in an oven, and keep at 80 °C Under reaction for 5 h. Take it out from the oven, cool it to room temperature, filter it with filter membrane (0.22 μm), wash it with deionized water several times, and finally dry the obtained purpl...

Embodiment 2

[0025] 1. Synthesis of cobalt-nickel bimetallic organic phosphonic acid compound microsphere precursor: Weigh 2.8 mmol of phenylphosphonic acid with an electronic balance, add it to 70 ml of deionized water, and prepare phenylphosphonic acid with a concentration of 0.04 mol / L Aqueous solution, called solution A; cobalt nitrate hexahydrate (Co(NO 3 ) 2 •6H 2 O) and nickel nitrate hexahydrate (Ni(NO 3 ) 2 •6H 2 O) Weigh 2.8 mmol according to the molar ratio of 7:3, and add it to 70 ml deionized water to form a solution with a concentration of 0.04 mol / L, which is called solution B. Mix the two solutions of A and B, stir evenly on a magnetic stirrer, then add 0.28 mol of urea, stir evenly after 45 min, transfer the mixture to a Teflon reactor, heat in an oven, and keep at 60 °C Under reaction 8 h. Take it out from the oven, cool it to room temperature, filter it with a filter membrane (0.22 μm), wash it with deionized water several times, and finally dry the obtained purple...

Embodiment 3

[0028] 1. Synthesis of cobalt-nickel bimetallic organophosphonic acid compound microsphere precursor: Weigh 3.6 mmol of phenylphosphonic acid with an electronic balance, add it to 90 ml of deionized water, and prepare phenylphosphonic acid with a concentration of 0.04 mol / L Aqueous solution, called solution A; cobalt nitrate hexahydrate (Co(NO 3 )2 •6H 2 O) and nickel nitrate hexahydrate (Ni(NO 3 ) 2 •6H 2 O) Weigh 3.6 mmol according to the molar ratio of 6:4, and add it to 90 ml deionized water to form a solution with a concentration of 0.04 mol / L, which is called solution B. Mix the two solutions of A and B, stir evenly on a magnetic stirrer, then add 0.36 mol of urea, stir evenly after 60 min, transfer the mixture to a Teflon reactor, heat in an oven, and keep at 70 °C Under the reaction 6 h. Take it out from the oven, cool it to room temperature, filter it with filter membrane (0.22 μm), wash it with deionized water several times, and finally dry the obtained purple p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com