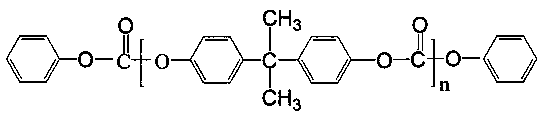

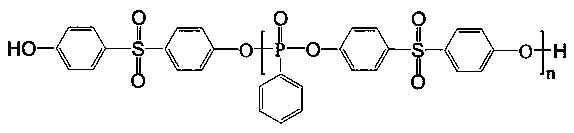

Polycarbonate/poly(bisphenol sulfone phenyl phosphonate) flame-retarding material and preparation method

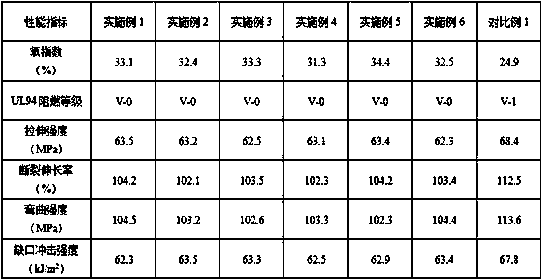

A technology of polyphenylphosphonic acid diphenyl sulfone ester and diphenyl carbonate is applied in the field of polycarbonate/polyphenylphosphonic acid diphenyl sulfone ester flame retardant materials and preparation, and can solve the problems of poor interface compatibility and mechanical properties. The problems of lowering, unsatisfactory dispersion flame retardant effect, etc., achieve the effects of good compatibility, improved oxygen index, and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add bisphenol A to the mixed solvent of dichloromethane and deionized water, then add excess diphenyl carbonate and sodium tetraphenylborate, stir for 17 minutes, then stand for 7 minutes to separate layers, take the oil phase and add methanol, Filter again, dry, make polycarbonate oligomer; The mol ratio of bisphenol A and diphenyl carbonate is 1:1.03; 0.7%;

[0033] (2) Mix phenylphosphonic dichloride with excess bisphenol S, add catalyst, heat up to 146°C for 34 minutes under nitrogen protection, then heat up to 228°C for 68 minutes, then cool and grind to obtain polyphenylphosphine acid diphenyl sulfone ester oligomer; the molar ratio of phenylphosphonic dichloride and bisphenol S is 1:1.26; the catalyst is antimony trioxide; the added weight of the catalyst is the weight sum of phenylphosphonic dichloride and bisphenol S 0.5% of

[0034] (3) Disperse the polycarbonate oligomer prepared in step (1) and the polyphenylsulfone disulfone phosphonate oligomer prepa...

Embodiment 2

[0036] (1) Add bisphenol A to the mixed solvent of dichloromethane and deionized water, then add excess diphenyl carbonate and sodium tetraphenylborate, stir for 16 minutes, then stand for 6 minutes to separate layers, take the oil phase and add methanol, Filter again, dry, make polycarbonate oligomer; The mol ratio of bisphenol A and diphenyl carbonate is 1:1.03; 0.6%;

[0037](2) Mix phenylphosphonic dichloride with excess bisphenol S, add catalyst, heat up to 142°C for 38 minutes under nitrogen protection, then heat up to 225°C for 75 minutes, then cool and grind to obtain polyphenylphosphine Acid diphenylsulfone ester oligomer; the molar ratio of phenylphosphonic dichloride and bisphenol S is 1:1.22; the catalyst is antimony acetate; the weight of the catalyst added is 0.4 of the weight sum of phenylphosphonic dichloride and bisphenol S %;

[0038] (3) Disperse the polycarbonate oligomer prepared in step (1) and the polyphenylsulfone disulfone phosphonate oligomer prepar...

Embodiment 3

[0040] (1) Add bisphenol A to the mixed solvent of dichloromethane and deionized water, then add excess diphenyl carbonate and sodium tetraphenylborate, stir for 19 minutes, then stand for 9 minutes to separate layers, take the oil phase and add methanol, Filter again, dry, make polycarbonate oligomer; The mol ratio of bisphenol A and diphenyl carbonate is 1:1.04; 0.7%;

[0041] (2) Mix phenylphosphonic dichloride with excess bisphenol S, add catalyst, raise the temperature to 148°C for 32 minutes under the protection of nitrogen, then raise the temperature to 235°C for 65 minutes, then cool and grind to obtain polyphenylphosphine Acid diphenyl sulfone ester oligomer; the molar ratio of phenylphosphonic dichloride and bisphenol S is 1:1.28; the catalyst is antimony trioxide; the added weight of the catalyst is the weight sum of phenylphosphonic dichloride and bisphenol S 0.5% of

[0042] (3) Disperse the polycarbonate oligomer prepared in step (1) and the polyphenylsulfone d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com