LED-UV printing ink initiator, preparation method thereof and LED-UV printing ink containing same

A technology of initiator and ink, which is applied in the field of ink and can solve the problems of poor use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

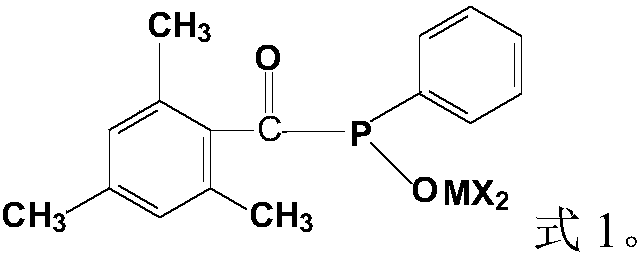

[0033] A novel LED-UV ink initiator, chemical structure as shown in formula 2, abbreviated as TPO-La(OTf) 2 .

[0034]

[0035] The chemical structure of the LED-UV ink initiator shown in formula 2, its synthesis process is as follows:

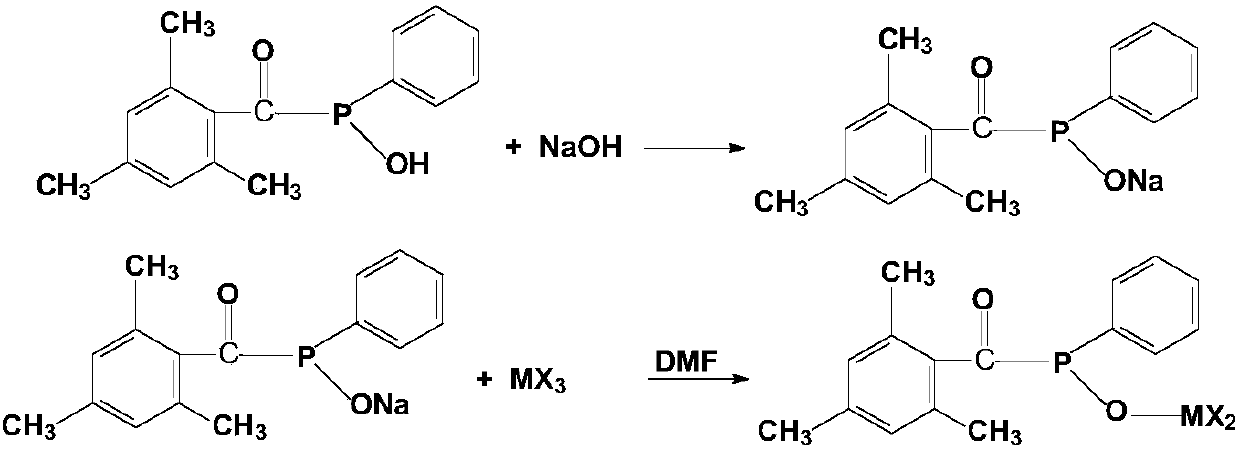

[0036] (1) Take a dry 500ml single-mouth ground flask, add a tetrafluoro stirring blade; heat the oil bath to 75°C-80°C, and add 2,4,6-trimethylbenzoylphenylphosphonic acid into the flask 29.9g, NaOH 4g, solvent THF 200g, fully stirred for 30min; then transfer the flask to a rotary evaporator to evaporate the aqueous THF solvent to obtain 2,4,6-trimethylbenzoylphenyl phosphonate sodium, dissolved in 300ml DMF for use;

[0037] (2) in N 2 In the 1000ml three-necked bottle under protection, add La(OTf) 3 64.5g of powder and 500ml of DMF, heated and stirred to dissolve; then, at 60°C, add the DMF solution of sodium 2,4,6-trimethylbenzoylphenylphosphonate obtained in step (1) dropwise to the three-necked flask After adding in about 1 hour,...

Embodiment 2

[0040] A novel LED-UV ink initiator, chemical structure as shown in formula 3, abbreviated as TPO-Tb (PFO) 2 .

[0041]

[0042] The chemical structure of the LED-UV ink initiator shown in formula 3, its synthesis process is as follows:

[0043](1) Take a dry 500ml single-mouth ground flask, add a tetrafluoro stirring blade; heat the oil bath to 75°C-80°C, and add 2,4,6-trimethylbenzoylphenylphosphonic acid into the flask 29.9g, NaOH 4g, solvent THF 200g, fully stirred for 30min; then transfer the flask to a rotary evaporator to evaporate the aqueous THF solvent to obtain 2,4,6-trimethylbenzoylphenyl phosphonate sodium, dissolved in 300ml DMF for use;

[0044] (2) in N 2 In the 1000ml three-neck bottle under protection, add Yb(PF0) 3 154.9g of powder and 500ml of DMF, heated and stirred to dissolve; then, at 60°C, add the DMF solution of sodium 2,4,6-trimethylbenzoylphenylphosphonate obtained in step (1) dropwise to the three-necked flask , Added in about 1 hour, conti...

Embodiment 3

[0047] A kind of LED-UV red ink, comprises the following components by weight percentage: coloring agent P.R.254 red 6%, active monomer tripropylene glycol diacrylate 30%, active monomer trimethylolpropane trimethacrylate 37% , prepolymer polyether acrylate (molecular weight 1000-3000) 15%, LED-UV ink initiator TPO-La (OTf) described in embodiment 1 2 1.5%, antifoaming agent dimethyl polysiloxane 2.5%, solvent butyl acetate 8%.

[0048] The preparation method of above-mentioned LED-UV red ink, concrete steps are as follows:

[0049] 1) Prepare the following raw materials: 6g of pigment P.R.254 red, 30g of tripropylene glycol diacrylate, 37g of trimethylolpropane trimethacrylate, 15g of polyether acrylate, TPO-La(OTf) 2 1.5g, 2.5g dimethyl polysiloxane, 8g butyl acetate.

[0050] 2) Mix and stir 6g of P.R.254 pigment, 12g of tripropylene glycol diacrylate, 37g of trimethylolpropane trimethacrylate, and 15g of polyether acrylate, and pour it into a grinder to grind into a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com