Resin special for anchoring agent and preparation method thereof

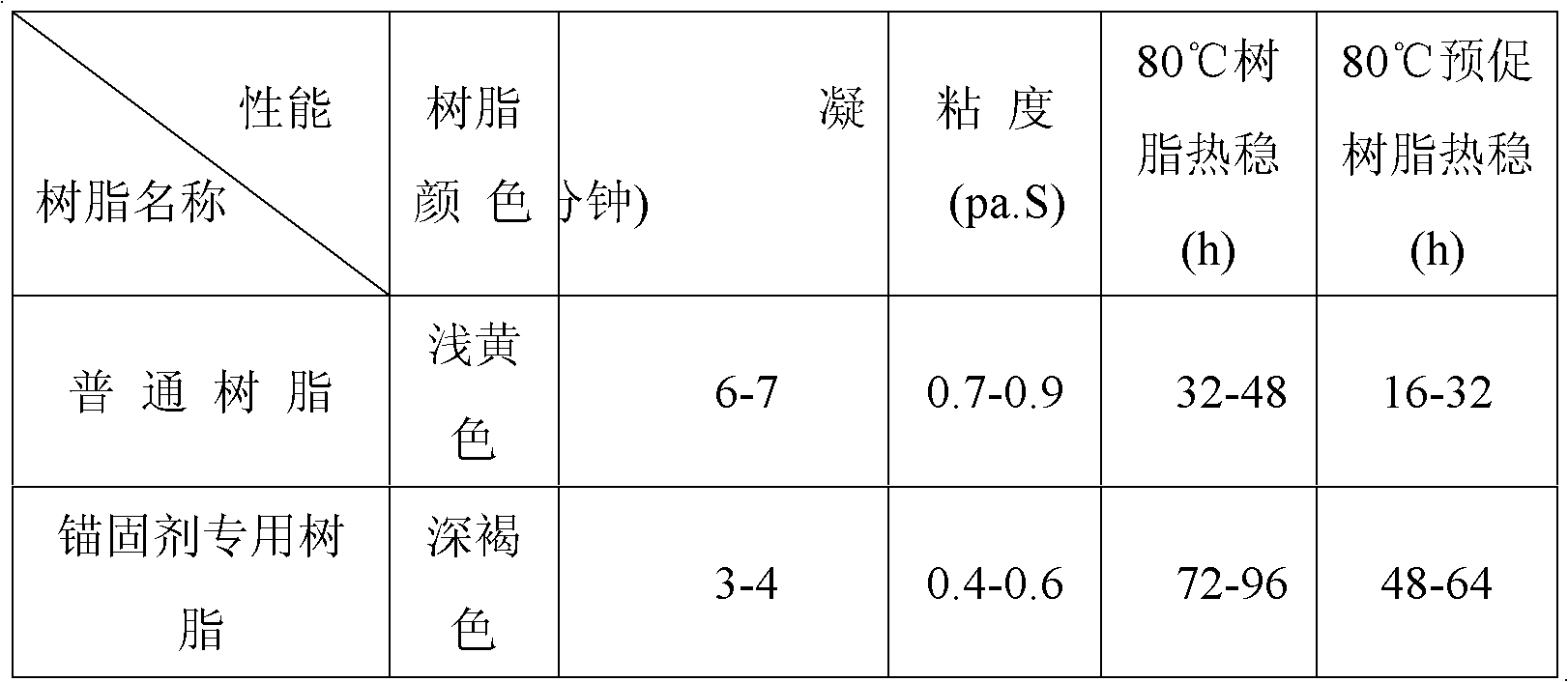

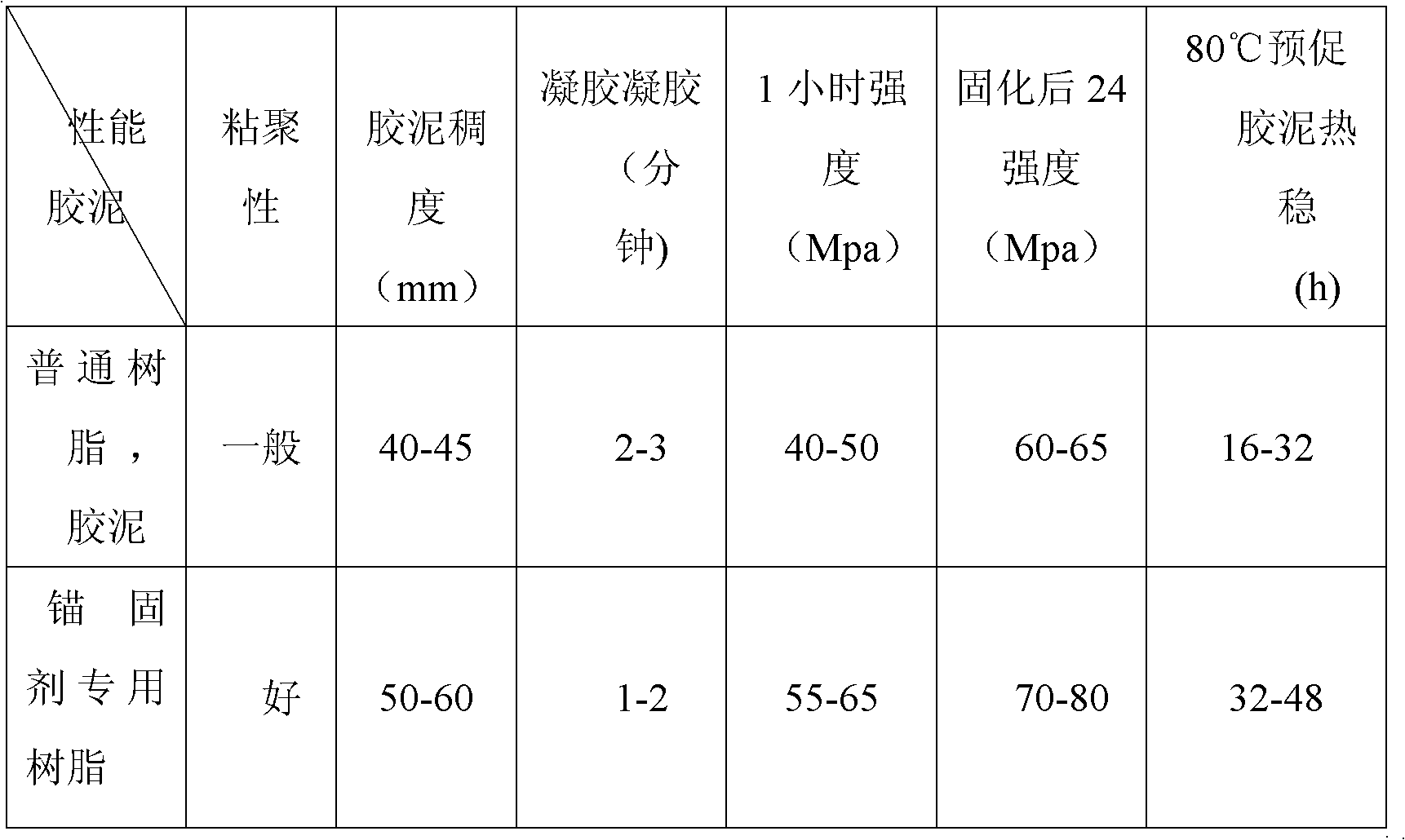

An anchoring agent and resin technology, applied in the field of unsaturated polyester resin and its preparation, can solve the problems of short storage period, slow strength development, poor high temperature resistance, etc., and achieve good thermal stability, fast strength development, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of special resin for anchoring agent, comprising the following steps:

[0016] (1) Put terephthalic acid, abietic acid, oxalic acid, glycerin, diethylene glycol, and catalyst into the reaction kettle according to the weight ratio of raw materials, stir, and electric heating to dissolve the raw materials, heat to 160 ° C for 1 hour, and continue to heat up , the temperature rise rate is controlled at no more than 15°C per hour, and the column temperature does not exceed 105°C. When the material rises to 230°C and the column temperature is 70-80°C, measure the acid value. If the acid value is ≤10mgKOH / g, proceed to the next step;

[0017] (2) Cool down to 200°C, put maleic anhydride and fumaric acid into the reactor according to the weight ratio, slowly raise the temperature, the heating rate is controlled at no more than 15°C per hour, the column temperature does not exceed 105°C, when the material rises to 220°C When the column temperature is 75-80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com