Preparation method of compound type cobalt stearate adhesion promoter

An adhesion promoter, cobalt stearate technology, applied in the field of material engineering, can solve the problem of difficult control of technical indicators, and achieve the effects of outstanding adhesion performance and anti-aging performance, improved performance, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Dissolve inorganic soluble cobalt salts in water, prepare a cobalt solution with a cobalt concentration of 15-45g / L (based on the amount of pure cobalt), and then prepare a sodium hydroxide solution with a concentration of 100-300g / L and a concentration of It is a sodium carbonate solution of 150-300g / L, and the above three solutions are filtered separately for later use;

[0025] (2) Heat the cobalt solution to 85±5°C, and slowly add a sodium hydroxide solution at a temperature of 40 to 50°C under stirring conditions. When the pH value of the reaction solution is 7, slowly add the solution at a temperature of For sodium carbonate solution at 40-50°C, when the pH value of the reaction solution is 9.5, stop adding sodium carbonate solution, maintain the temperature at 50-60°C, and continue stirring until the pH value does not change;

[0026] (3) The reaction solution obtained in step (2) is left to stand, and the precipitate is rinsed with water until the pH value o...

Embodiment 2

[0034] With the method of embodiment 1, difference is the difference of adding raw material amount in the step (6): first add the rosin acid of 48.8kg and xylene solvent miscible after step (5) makes 151.5kg cobalt Add and mix the powder, heat up to the melting point of stearic acid (about 70°C) at a speed of 30°C / h and add 603.5kg of stearic acid, then slowly add 29kg of isooctanoic acid under airtight conditions, and the input time is controlled at 0.5 to 2 hours In between, in order to ensure that all the materials react, the temperature of the materials is increased to 140°C at a rate of 20°C / h and kept for 2 hours.

[0035] Its physical and chemical performance parameters are listed in Table 2.

[0036] The physical and chemical performance parameters of the composite cobalt stearate adhesion promoter product that table 2 embodiment 2 makes

[0037] project

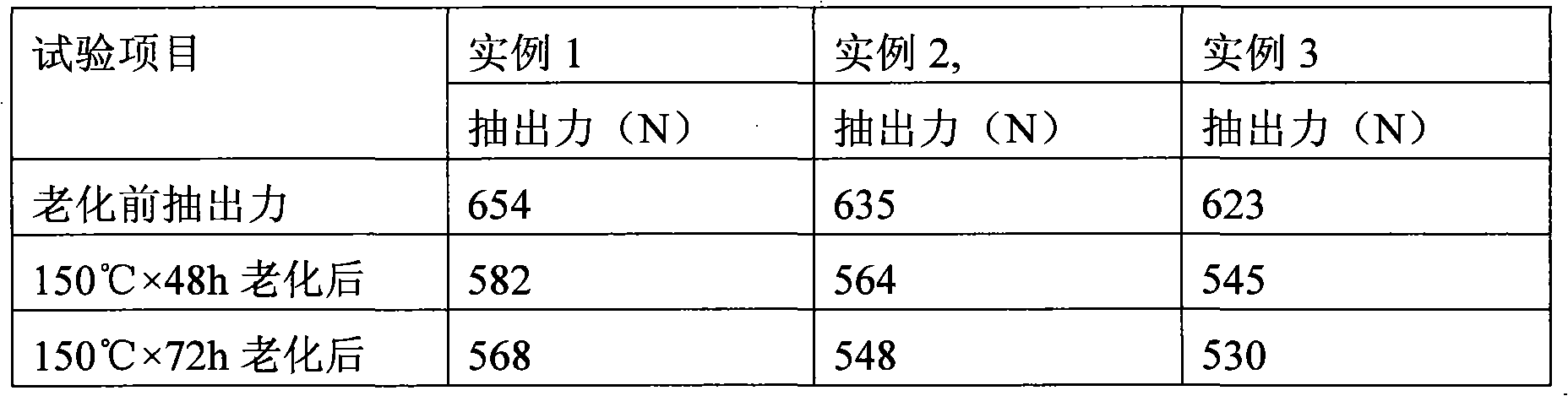

Embodiment 3

[0038] Embodiment 3 (comparative example):

[0039] Steps (1)-(5) and step (7) are the same as in Example 1, except for step (6).

[0040] Specifically: react 151.5kg of cobalt powder prepared with 720kg of stearic acid in solvent gasoline (boiling point at 150-175°C) environment, when the reaction temperature is below 100°C, heat up at a rate of 30°C / h, When the reaction temperature is 100-140°C, the temperature is raised at a rate of 5°C / h; when the reaction temperature is 140-160°C, the temperature rise time is controlled at 4 hours, and when the temperature reaches 160°C, the reaction ends, from feeding to discharging The reaction time is about 20 hours.

[0041] The physical and chemical performance parameters of the obtained organic cobalt salt adhesion promoter product (cobalt stearate) are shown in Table 3.

[0042] The physical and chemical property parameter of the cobalt stearate that table 3 embodiment 3 makes

[0043] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com