Ultraviolet light polymerized low polymer synthesized by utilizing rosin derivatives and preparation method of polymer

A technology of rosin derivatives and light-curing inks, which is applied in rosin coatings, applications, household appliances, etc., can solve problems such as adhesion, poor emulsification, high production costs, and poor light-curing performance, and achieve broad market prospects and save money. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

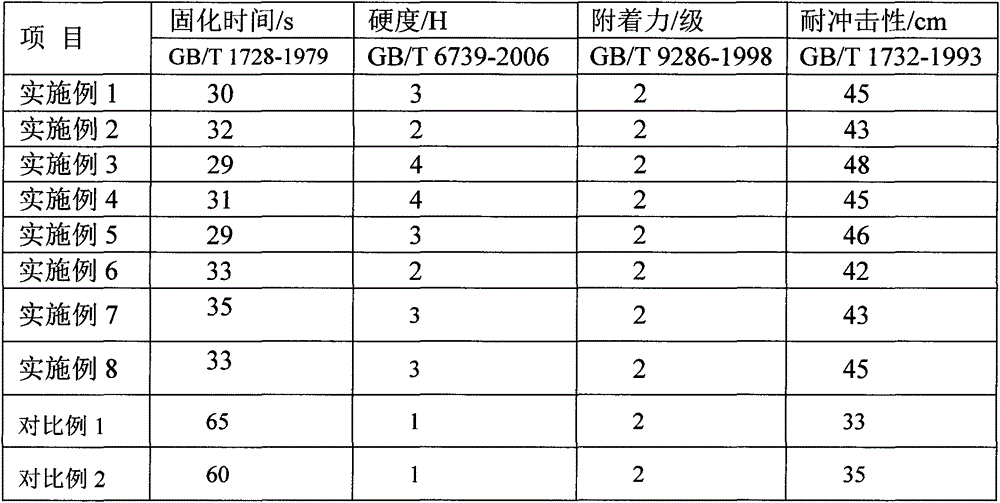

Examples

Embodiment 1

[0048] Adopt split flow uniform distribution feeding reactor of the present invention, wherein stainless steel reactor volume is 1m 3 , the distance between the stirring paddle and the inner wall of the reactor is 20mm, the diameter of the distributor is DN40, and the length of the distributor is 1000mm; the inner diameter of the short tube with the lower opening is DN8, and the length of the short tube is 10mm. In the reactor, add 85 parts of abietic acid, 15 parts of diethylene glycol, add 0.3 parts of catalyst, protect it with nitrogen, heat to 120-125 °C to melt all the abietic acid, keep the pressure at 0.1MPa, and keep warm for 2-2 After 4 hours, cool down to 80-100°C, add 10 parts of acrylic acid dropwise, finish dropping in 30 minutes, keep warm for 3-4hrs; evacuate to -0.07-0.098MPa, cool down to 50°C and discharge.

Embodiment 2

[0050] Adopt split flow uniform distribution feeding reactor of the present invention, wherein stainless steel reactor volume is 1.5m 3 , the distance between the stirring paddle and the inner wall of the reactor is 25mm, the diameter of the distributor is DN50, and the length of the distributor is 1300mm; the inner diameter of the short tube with the lower opening is DN10, and the length of the short tube is 10mm. In the reactor, add 75 parts of abietic acid, 25 parts of dipropylene glycol, add 0.5 parts of catalyst, pass nitrogen protection, heat to 130-140 °C to melt all the abietic acid, keep the pressure at 0.1MPa, keep warm for 2-4hrs, After cooling down to 80-100°C, add 20 parts of acrylic acid dropwise for 30 minutes, keep warm for 3-4 hours; vacuumize to -0.07-0.098MPa, cool down to 50°C and discharge.

Embodiment 3

[0052] Adopt split flow uniform distribution feeding reactor of the present invention, wherein stainless steel reactor volume is 2.5m 3 , the distance between the stirring paddle and the inner wall of the reactor is 35mm, the diameter of the distributor is DN65, and the length of the distributor is 1500mm; the inner diameter of the short tube with the lower opening is DN12, and the length of the short tube is 12mm. In the reactor, add 85 parts of hydrogenated abietic acid, 25 parts of tripropylene glycol, add 0.5 part of catalyst, pass nitrogen protection, heat to 150°C to melt all the abietic acid, keep the pressure at 0.1MPa, keep it warm for 2 to 4 hours, and then Cool down to 80-100°C, add 20 parts of acrylic acid dropwise, finish dropping in 30 minutes, keep warm for 3-4 hours; vacuumize to -0.07-0.098MPa, cool down to 50°C and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com