Aqueous polyurethane-acrylate resin for use as foaming material for synthetic leather and preparation method thereof

A technology of water-based polyurethane and acrylate, which is applied in the direction of textiles and papermaking, can solve the problems of environmental and human health hazards, low solid content of water-based polyurethane, process procedures, equipment and cost increase, etc., and achieve good mechanical foaming performance, The effect of stable emulsion performance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

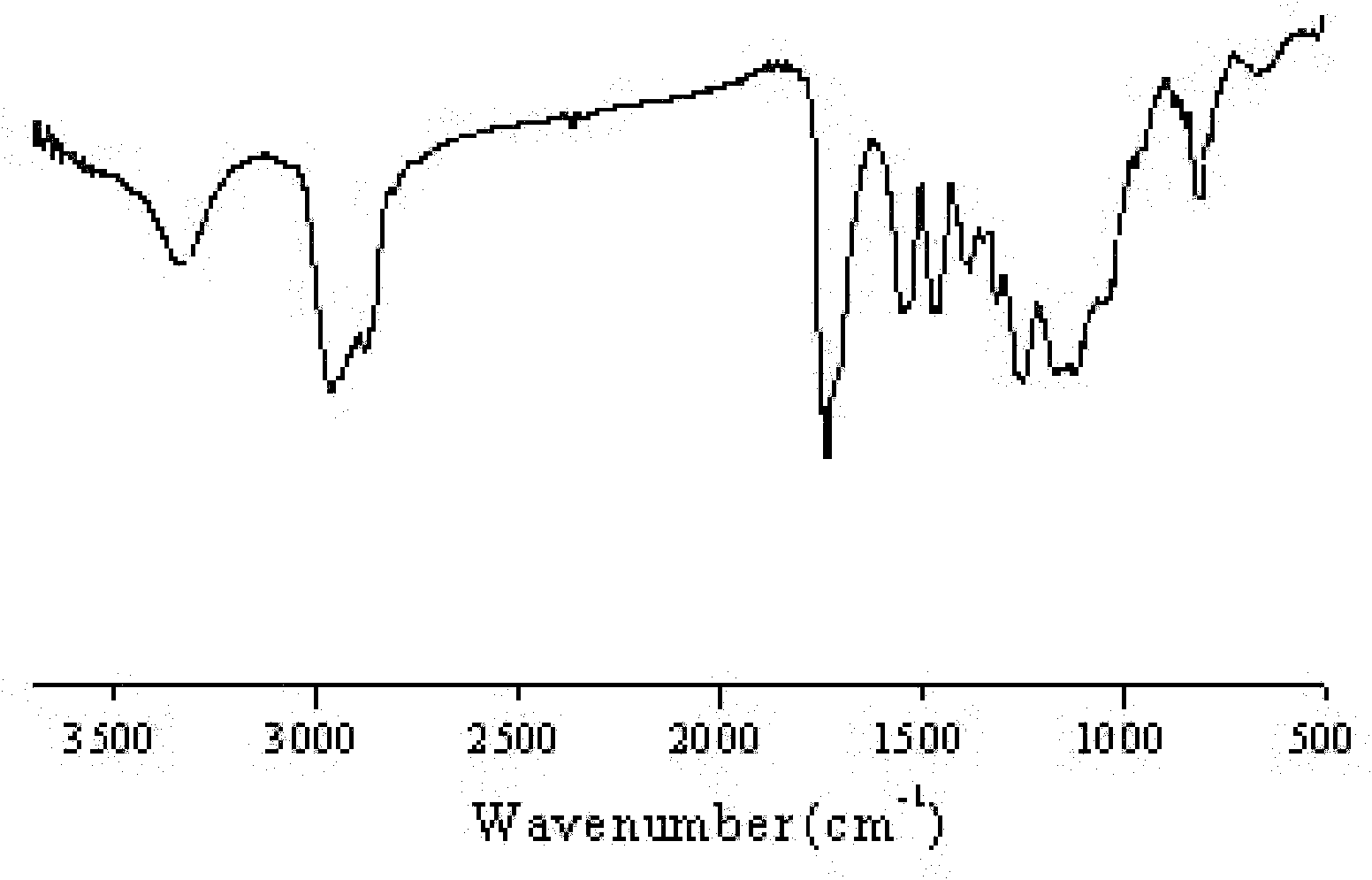

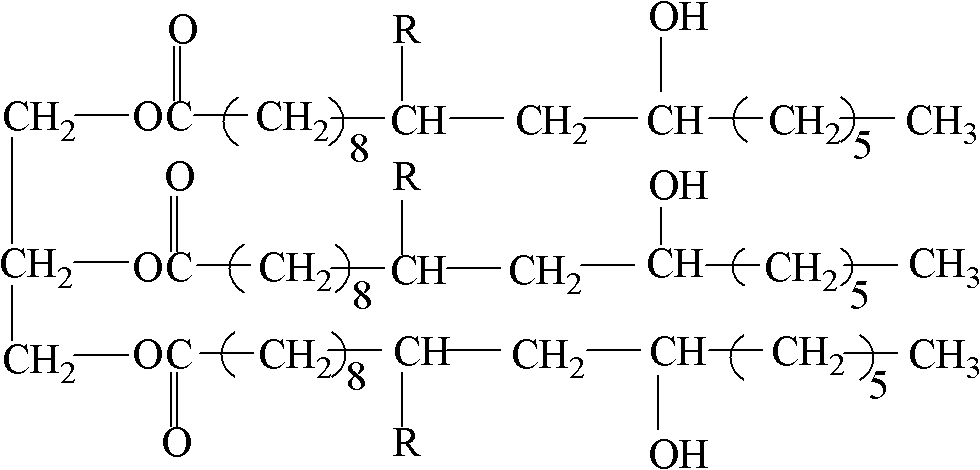

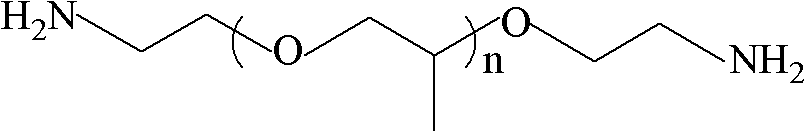

[0022] 26 grams of castor oil-based polysiloxane polyol (Mn=2000) and 64 grams of polypropylene oxide polyol (Mn=2000) were dehydrated at 120° C. for 1 hour, added 23.5 grams of TDI, and reacted at 90° C. 4 hours; Add 6.8 grams of dimethylol propionic acid and 0.7 grams of ethylene glycol, react for 3 hours at 80 ° C, add 30 grams of hydroxypropyl acrylate and 15 grams of methyl methacrylate and 5 The acrylic acid dilution of gram, obtains the polyurethane prepolymer that end group is NCO group; The polyurethane prepolymer is transferred to the high-speed shear disperser, adds 5.2 grams of triethylene glycol under 800 rev / min high-speed shear and 20 ℃ of conditions The amine reacts for 2 minutes, increase the speed to 2500-4000 rpm and then add 340 grams of water. After 5 minutes, a polyurethane emulsion with NCO group as the end group is obtained; under the condition of stirring below 20 °C and 1000-1500 rpm , slowly add 19 grams of α, ω-amino-terminated polyoxypropylene (Mn=...

Embodiment 2

[0026] 16 grams of castor oil-based polysiloxane polyol (Mn=2000) and 74 grams of PTMG (Mn=2000) were dehydrated at 120°C for 1 hour, added 23.5 grams of MDI, and reacted at 90°C for 4 hours; gram of dimethylol butyric acid and 0.9 gram of butanediol, reacted for 3 hours at 80°C, added 30 grams of methyl methacrylate and 30 grams of butyl acrylate for dilution during the reaction, and the end group was NCO group Polyurethane prepolymer of agglomerate; Transfer the polyurethane prepolymer into high-speed shear disperser, add 5.2 grams of triethylamine to react for 2 minutes under high-speed shear of 800 rpm and 20°C, and increase the speed to 2500-4000 Then add 340 grams of water after 5 minutes to obtain a polyurethane emulsion with NCO groups at the end; slowly add 19 grams of α, ω-terminated amino groups under the condition of stirring below 20°C and 1000-1500 rpm After polyoxypropylene (Mn=600) carried out chain extension, after stirring for 5 minutes, water-based polyureth...

Embodiment 3

[0029]16 grams of castor oil-based polysiloxane polyol (Mn=2000) and 74 grams of PCL (Mn=2000) were dehydrated at 120°C for 1 hour, added 23.5 grams of HTDI, and reacted at 90°C for 4 hours; adding 6.8 The dimethylol valeric acid of 1 gram and the dimethylol cyclohexane of 0.9 gram were reacted at 80 ℃ for 3 hours, and 30 gram of hydroxyethyl acrylate and 30 gram of methacrylonitrile were added in the reaction process to dilute to obtain terminal The base is the polyurethane prepolymer of NCO group; The polyurethane prepolymer is transferred to a high-speed shear disperser, and 5.2 grams of triethylamine are added to react for 2 minutes at 800 rpm high-speed shear and 20°C, and the rotating speed is increased. Add 340 grams of water to 2500-4000 rpm and then add 340 grams of water. After 5 minutes, a polyurethane emulsion with NCO group as the end group is obtained; under the stirring condition of 1000-1500 rpm below 20 ° C, slowly add 24 grams of α , ω-amino-terminated polyox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com