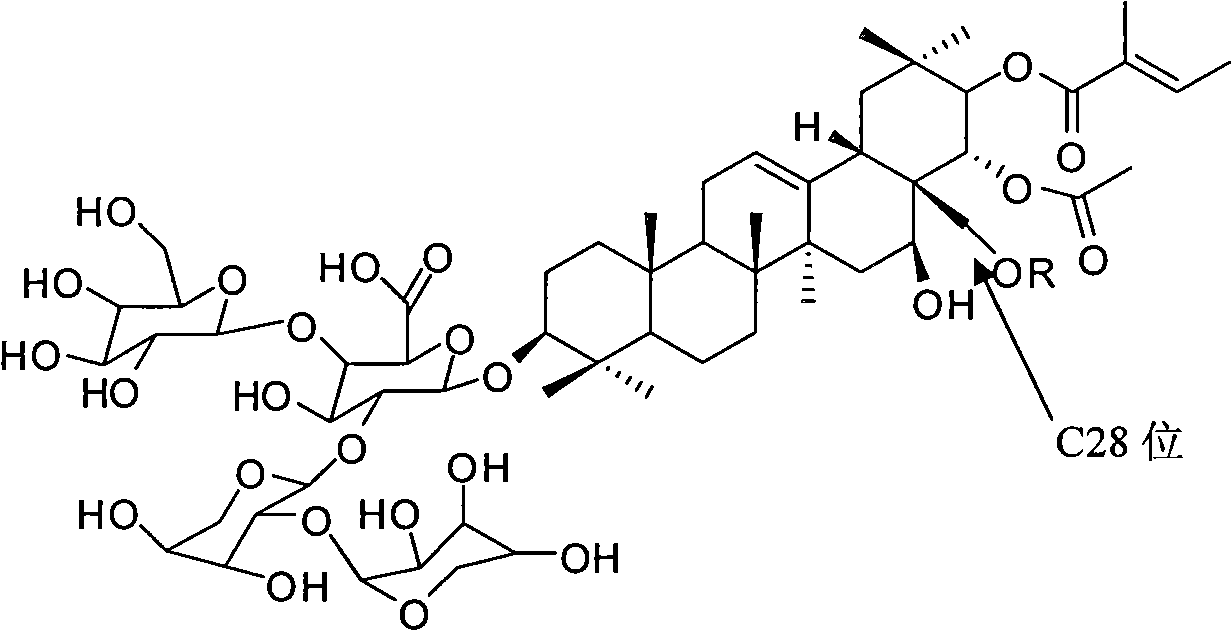

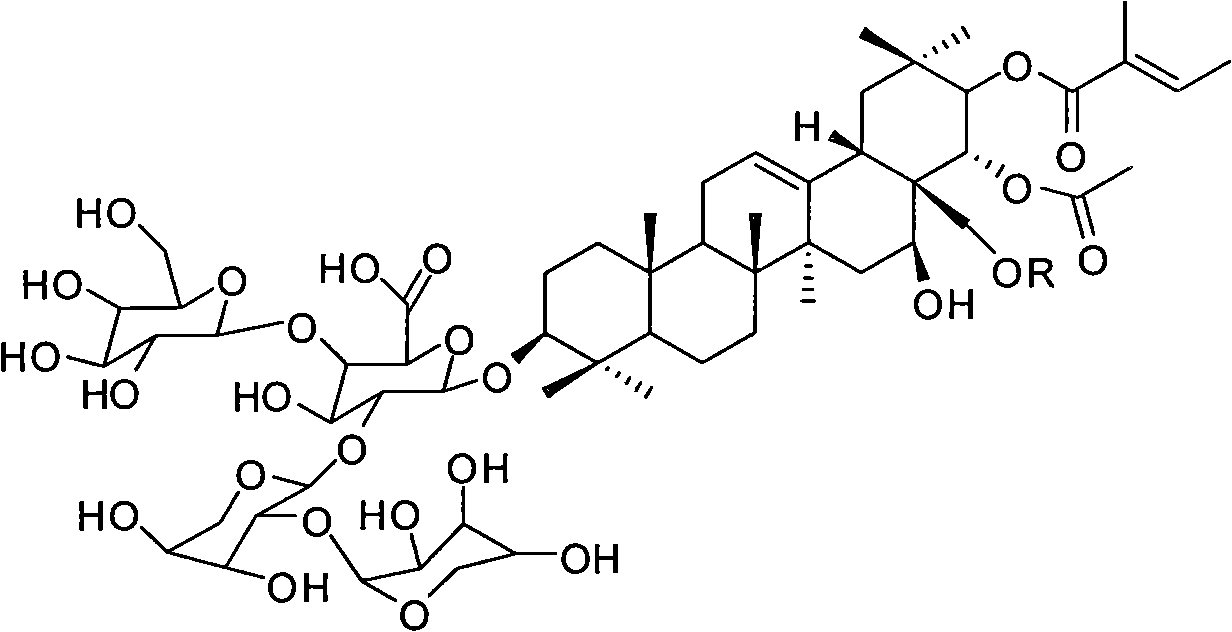

Theasaponin derivative as well as preparation method and application thereof

A technology of tea saponin and derivatives, which is applied in the field of tea saponin derivatives and its preparation, can solve the problems of poor foam stabilizing performance of tea saponin, achieve strong foaming power and foam stabilizing performance, simple process, and easy control of reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 100 g of tea saponin into 300 mL of pyridine, and heat to 50° C. to dissolve it. Add triphenylchloromethane (23g) in an equimolar amount to tea saponin, keep stirring at 50°C for 8h; add potassium hydroxide (4.6g) with 1 / 5 mass of triphenylchloromethane, raise the temperature to 80°C, and stir for 1h , evaporate water and pyridine under reduced pressure. Then add 500mL of toluene to dissolve, raise the temperature to 120°C, slowly add benzyl bromide (170g) which is 12 times the molar amount of tea saponin, and stir for 8 hours. The reaction solution is called A solution;

[0031] (2) Take glucose (14.8g) in an equimolar amount to tea saponin, add 100mL of toluene, add phosphorus tribromide (7.4g) dropwise at 30°C, react for 3h, raise the temperature to 120°C, and slowly add glucose Benzyl bromide (56g) of 4 times the molar amount was stirred and reacted for 8h, and the reaction solution was called liquid B;

[0032] (3) Mix liquid A and liquid B, add 21 g of p...

Embodiment 2

[0036] (1) Add 100 g of tea saponin into 300 mL of pyridine, and dissolve it at room temperature (25° C.). Add triphenylchloromethane (34.5g) according to 1.5 times the molar amount of tea saponin, and stir for 16h; then add potassium hydroxide (6.9g) with 1 / 5 mass of triphenylchloromethane, heat up to 80°C, and stir for 1h. Evaporate water and pyridine under reduced pressure; add 500mL of toluene to dissolve, heat up to 140°C, slowly add benzyl bromide (200g) with 14 times the molar amount of tea saponin, and stir for 6 hours. The reaction solution is called A solution;

[0037] (2) Take another fructose (14.8g) in an equimolar amount to tea saponin, add 100mL of toluene, add phosphorus tribromide (7.4g) dropwise at 20°C, react for 5h, raise the temperature to 140°C, slowly add fructose 5 times The molar amount of benzyl bromide (70g) was stirred and reacted for 6h, and the reaction solution was called B liquid;

[0038] (3) Mix liquid A and liquid B, add 31 g of pyridinium ...

Embodiment 3

[0042] (1) Add 100g of tea saponin into 300mL of pyridine, and heat to 40°C to dissolve it. Add triphenylchloromethane (27.6g) according to 1.2 times the molar amount of tea saponin, keep stirring and react for 12h; then add potassium hydroxide (5.5g) with 1 / 5 mass of triphenylchloromethane, raise the temperature to 80°C, and stir for 1h , evaporate water and pyridine under reduced pressure; then add 500mL toluene to dissolve, heat up to 130°C, slowly add benzyl bromide (183g) with 13 times the molar amount of tea saponin, and stir for 7h, the reaction solution is called A solution;

[0043] (2) Take another arabinose (12.3g) in an equimolar amount to tea saponin, add 100mL of toluene, add phosphorus tribromide (7.4g) dropwise at 25°C, react for 4h, raise the temperature to 130°C, and slowly add arabinose dropwise Benzyl bromide (56g) of 4 times the molar amount was stirred and reacted for 7h, and the reaction solution was called liquid B;

[0044] (3) Mix liquid A and liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com