Method for manufacturing toilet soap by virtue of chlorella residues produced after extraction of algae oil

A technology of chlorella and soap, which is applied in the field of daily chemicals, can solve the problems of chlorella residue treatment, waste of chlorella algae oil, difficult promotion and implementation, etc., and achieves low cost, cost saving and strong foaming power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, preparation of chlorella soap

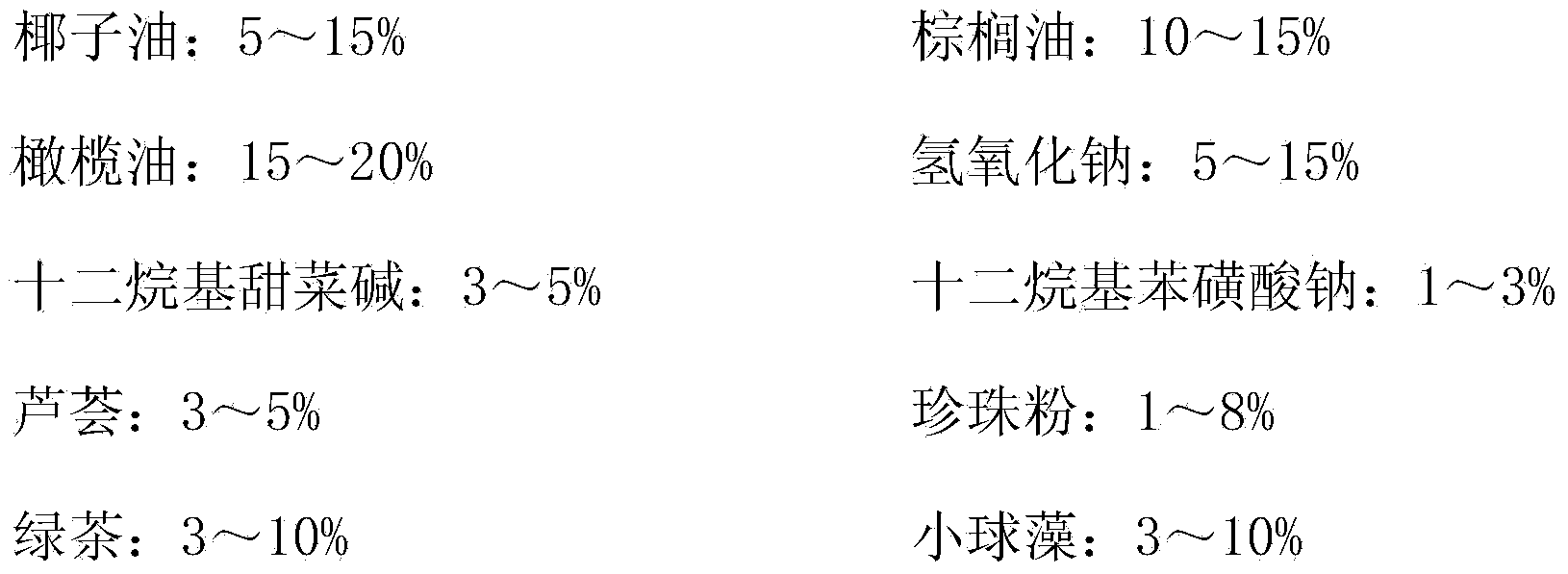

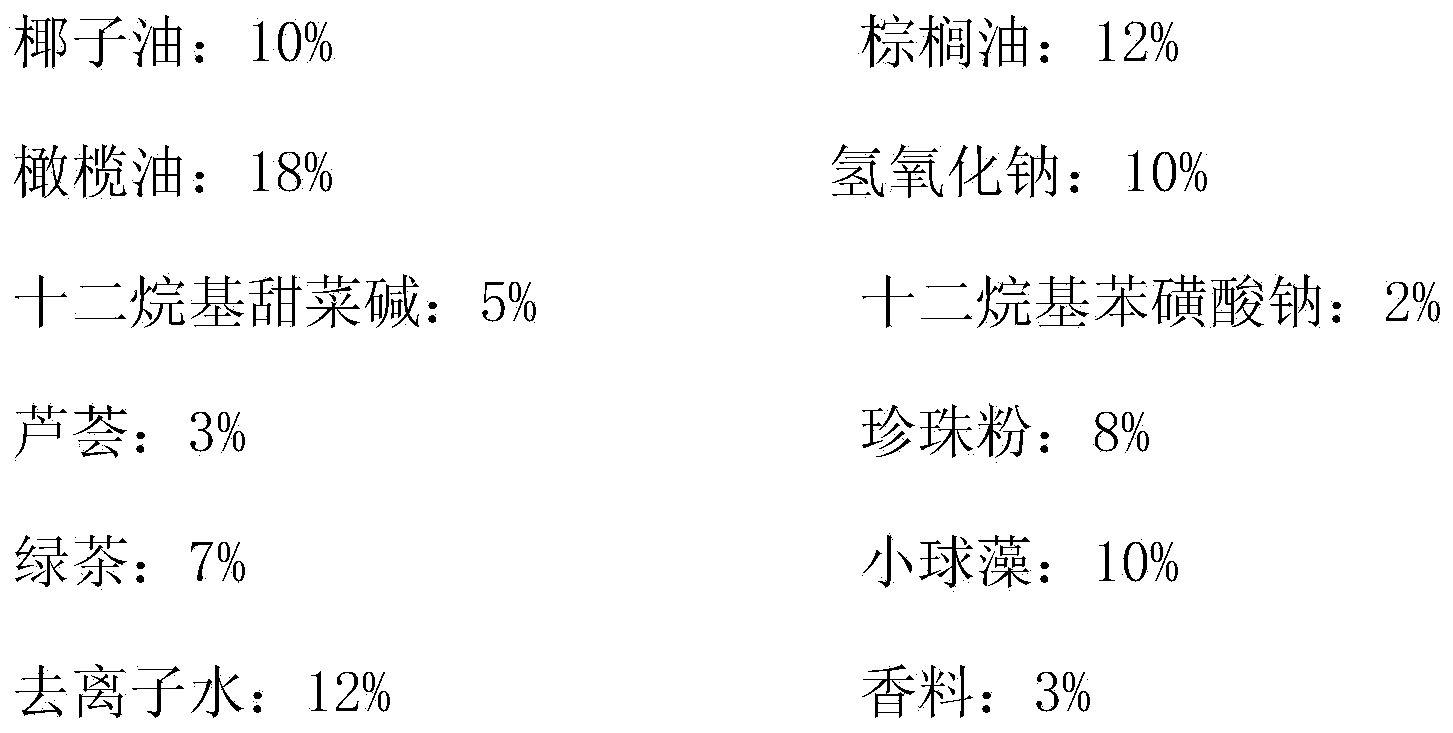

[0042]

[0043]

[0044] Craftsmanship:

[0045] 1. Saponification

[0046] 1) Mix olive oil, coconut oil, and palm oil according to the above ratio, heat, mix well, and keep the temperature at 40-50°C;

[0047] 2) Dissolve sodium hydroxide with water, and control the temperature at 38-55°C, and the temperature difference between the mixed oil temperature and the lye is 2-5°C;

[0048] 3) Pour the prepared sodium hydroxide solution into the soap liquid under stirring;

[0049] 4) Stir continuously for 3 to 8 minutes until the soap liquid becomes a thick paste.

[0050] 2. Add additives

[0051] 1) Add dodecyl betaine, sodium dodecylbenzenesulfonate and chlorella to the soap liquid obtained by saponification, and stir for 1 hour;

[0052] 2) Put the aloe vera, pearl powder and green tea into the cooking pot, add 60% water and cook for 50 minutes;

[0053] 3) Filter the decocted mix...

Embodiment 2

[0059] Embodiment 2, decontamination case

[0060] For a light-colored shirt stained with oil, moisten the blood-stained area with water at 30-40°C, wipe it with the chlorella soap prepared in Example 1 until the foaming film is formed, then gently rub the blood-stained area with your hands for 1-2 minutes, rinse with water, The blood stains on the light-colored shirts were completely washed away, and there were no surrounding clean spots and no color difference after drying.

Embodiment 3

[0061] Example 3, acne case

[0062] Zhang, female, 16 years old, a large amount of comedo (acne acne) appeared on the forehead for more than 3 months, and the comedo was white-headed, and the chlorella soap prepared by embodiment 1 was used for 1 month to recover.

[0063] Han, male, 18 years old, has acne, pustules and cysts around the lips. The acne is double-headed, and the cyst contains mucopurulent substances. Several acnes are aggregated together. The diagnosis is acne conglomerate, and the preparation in Example 1 is used. The chlorella soap for 2 months, healed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com