Preparation method of polyvinyl alcohol microcellular foam material

A microcellular foaming material and polyvinyl alcohol technology are applied in the field of preparing polyvinyl alcohol microcellular foaming materials by using supercritical fluid technology, and can solve the problems of unstable performance of foaming materials, residual materials, incompetence and the like, Shorten saturation time, improve foaming efficiency, and achieve good pore size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of polyvinyl alcohol microcellular foaming material of the present invention comprises step 1, step 2 and step 3;

[0021] Step 1: Place the polyvinyl alcohol composition in the pressure vessel A, and seal the pressure vessel A, raise the temperature to the infiltration temperature, the infiltration temperature is 40°C-110°C, fill the supercritical fluid to the infiltration pressure, the infiltration pressure is 1-100°C 15MPa, then infiltrate under the infiltration temperature and pressure, and the infiltration time is 10-600min;

[0022] Step 2: The temperature of pressure vessel B is kept at the saturation temperature, and the saturation temperature is 120°C ~ 160°C, and then go through the "unload-take-install-close-fill" procedure, and the "unload-take-install-close-fill" procedure Complete within 5 minutes, then the pressure vessel B is saturated at the saturation temperature and pressure, and the saturation time is 10-60 minutes.

[0023] T...

Embodiment 1

[0067] The polyvinyl alcohol sheet (the raw material used is Japan Kuraray PVA217, the degree of alcoholysis is 88%, the degree of polymerization is 1700, and the size is 40cm×40cm×2cm), in the polyvinyl alcohol composition constituting the sheet, ethylene glycol is 20wt% , glycerol is 20wt%. Place in pressure vessel A, and seal pressure vessel A, raise the temperature to 100°C, fill with supercritical carbon dioxide to 12MPa, and then soak for 120min;

[0068] The temperature of pressure vessel B is kept at 140°C, and then it goes through the "unload-take-install-close-fill" procedure, and the completion time of the "unload-take-install-close-fill" procedure is 115s, and then pressure vessel B is saturated Saturated under temperature and saturation pressure, the saturation time is 30 minutes, the specific steps of the "unloading-taking-installing-closing-filling" procedure are: depressurize the pressure vessel A, and take out the soaked polyvinyl alcohol sheet from the pressu...

Embodiment 2

[0072] Except for changing the polyvinyl alcohol raw material (Sinopec, PVA088-20, degree of alcoholysis 88%, degree of polymerization 1700) constituting the polyvinyl alcohol sheet in Example 1, it was the same as Example 1.

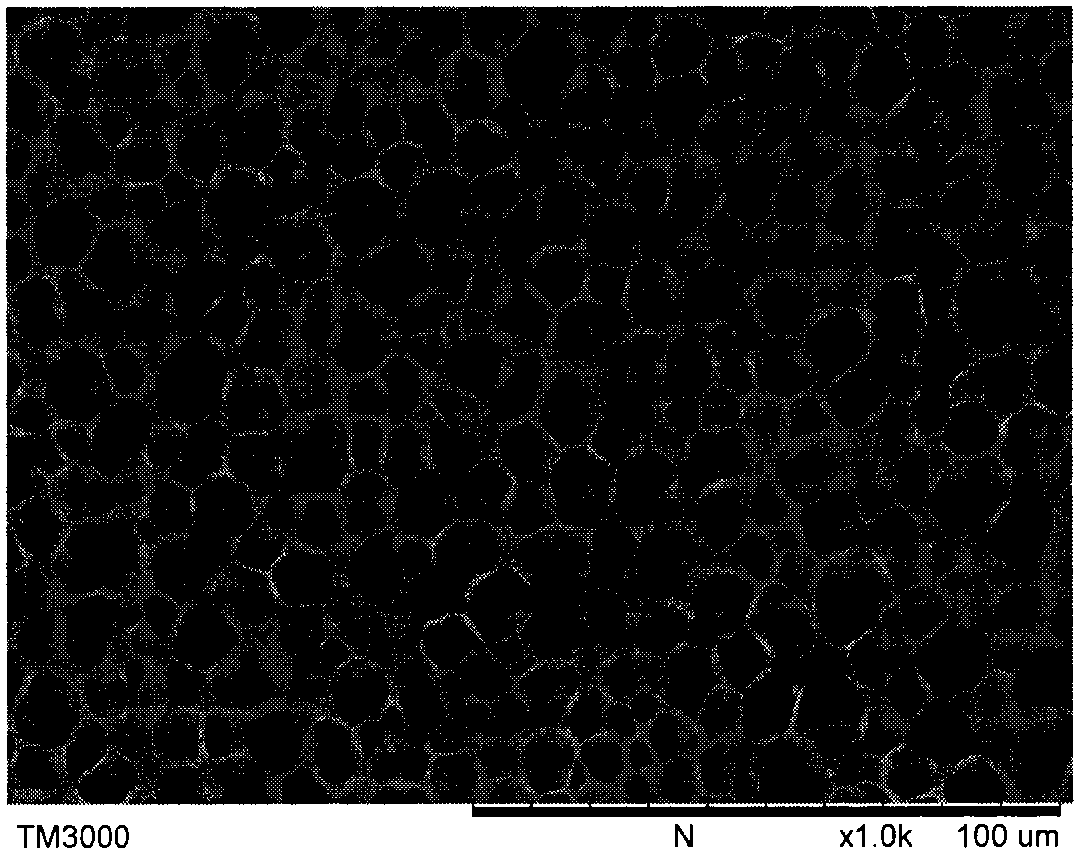

[0073] The prepared polyvinyl alcohol microcellular foamed sheet was analyzed by scanning electron microscopy for its internal cell morphology, as shown in figure 2 As shown, the measured average pore diameter is 16 μm, and the number of cells whose diameter is more than 2 times the average diameter is 1.8%. The cell uniformity is good, and the calculated cell density is 5.13×10 9 piece / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com