Preparation process of polycarbonate foamed sheet and product of preparation process

A polycarbonate and foam sheet technology, applied in the field of plastic foam materials, can solve the problems of high pressure and high equipment requirements, and achieve the effect of reducing pressure, low equipment requirements, and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Put a PC sheet with a thickness of 0.5mm into the autoclave, and pass it into a high-pressure CO with a pressure of 3MPa. 2 fluid, the saturation temperature is 25°C, and the saturation time is 1h to obtain a saturated PC sheet. After the PC sheet was placed in the atmosphere for 5 seconds, the PC sheet was foamed in an air blast oven at a temperature of 170°C for 35 seconds to obtain a PC microfoamed sheet.

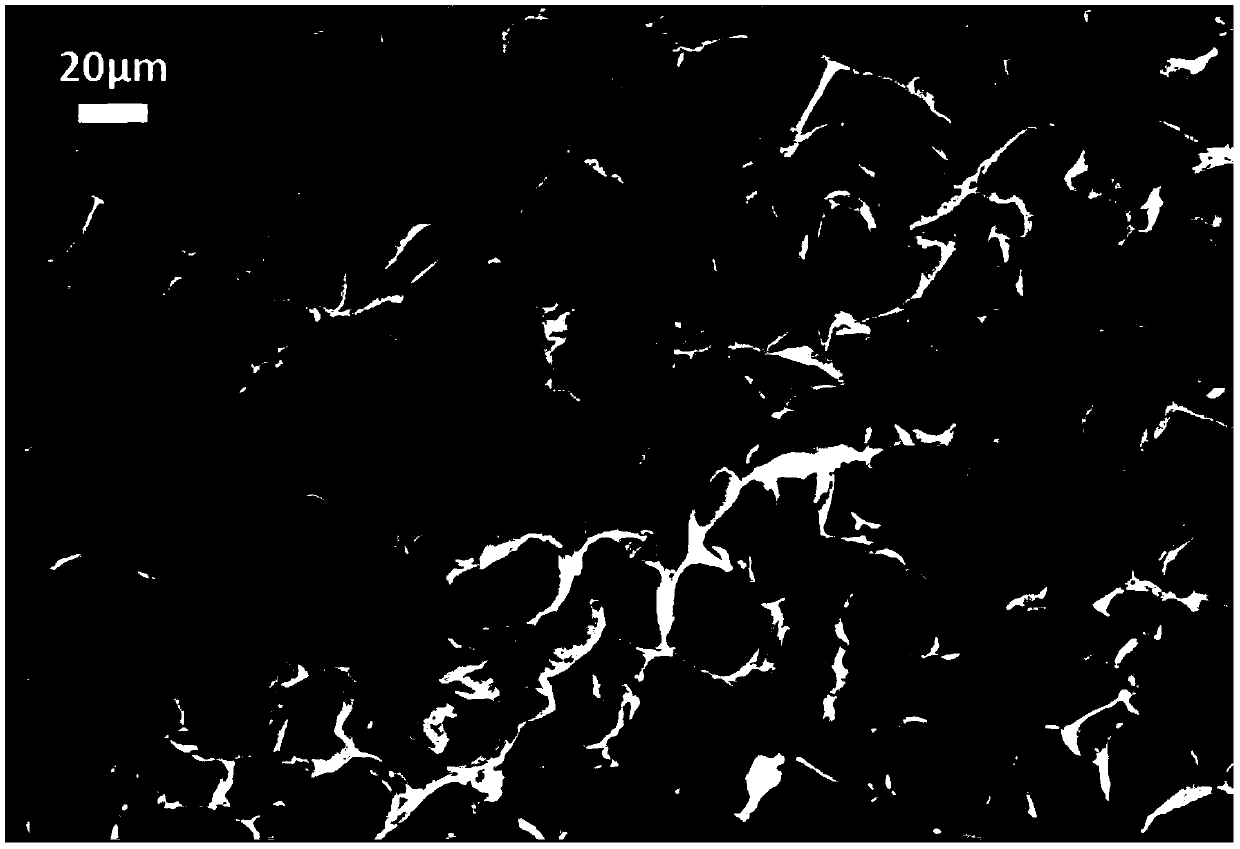

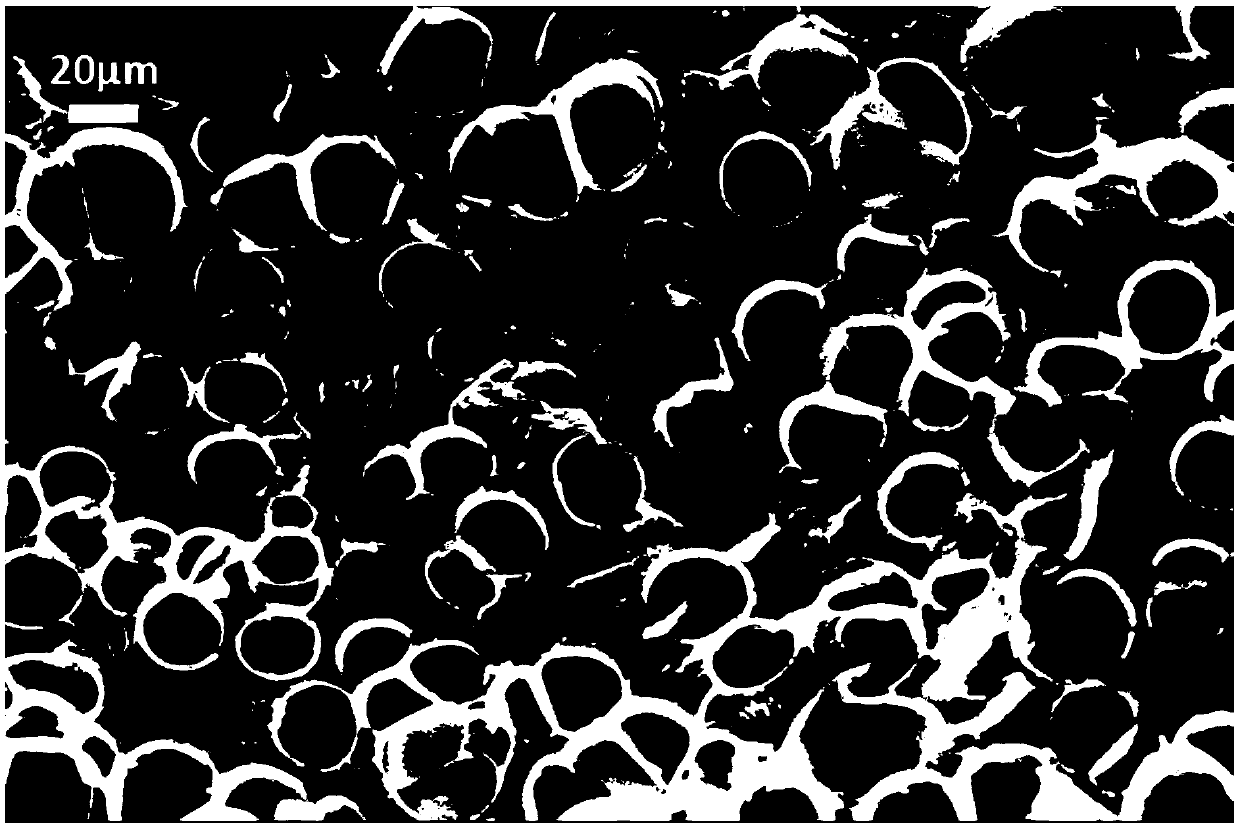

[0046] The prepared PC micro-foamed sheet has a smooth and smooth appearance structure, and the quenched section of the PC micro-foamed sheet sample is analyzed by scanning electron microscope, as shown in figure 1 As shown, the cell size of the PC microfoamed sheet is 10-30 μm, the cell size distribution is uniform, and the density is 0.55 g / cm 3 .

Embodiment 2

[0048] In this embodiment, except that the thickness of the PC sheet is 3mm, the saturated PC sheet is placed in the atmosphere for 2h before foaming, and other conditions are the same as in Example 1, and the cell size of the prepared PC microfoamed sheet is 10~30μm, the cell size distribution is uniform, and its density is 0.80g / cm 3 .

Embodiment 3

[0050] In this example, except that the saturation pressure is changed to 2.0MPa, other conditions are the same as in Example 1. The cell size of the prepared PC microfoam sheet is 20-40 μm, the cell size distribution is uniform, and its density is 0.65g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com