Patents

Literature

36results about How to "Good pore size uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

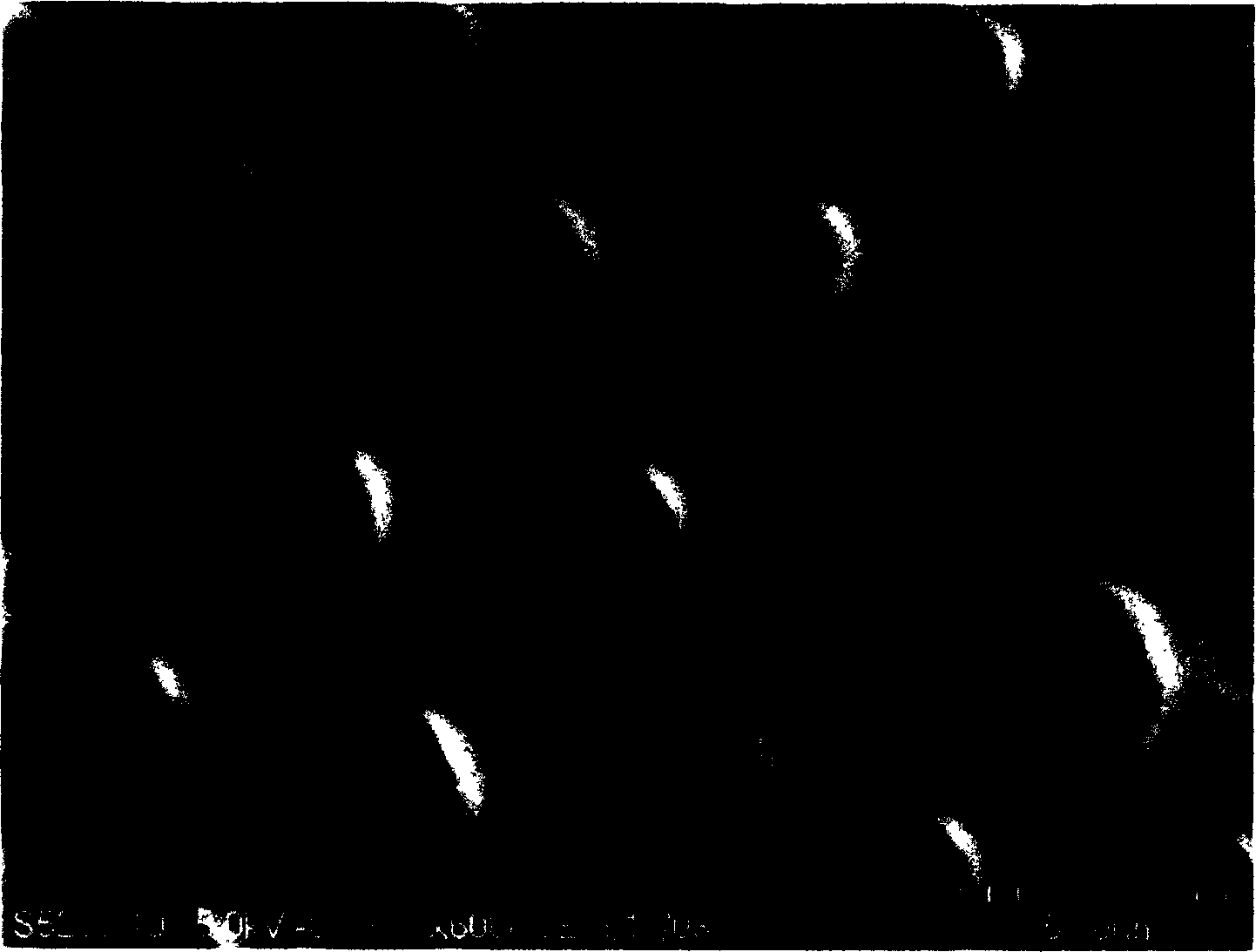

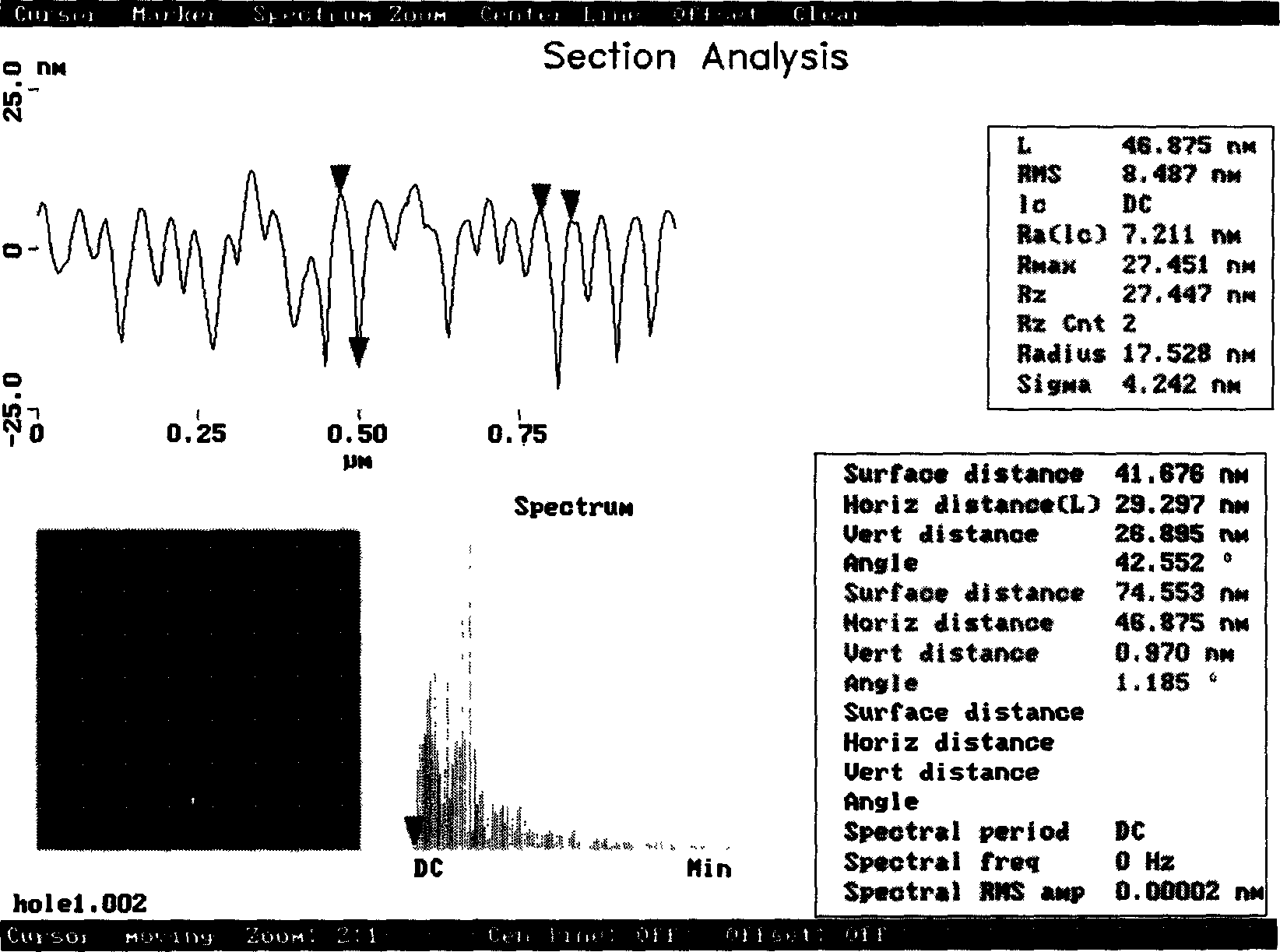

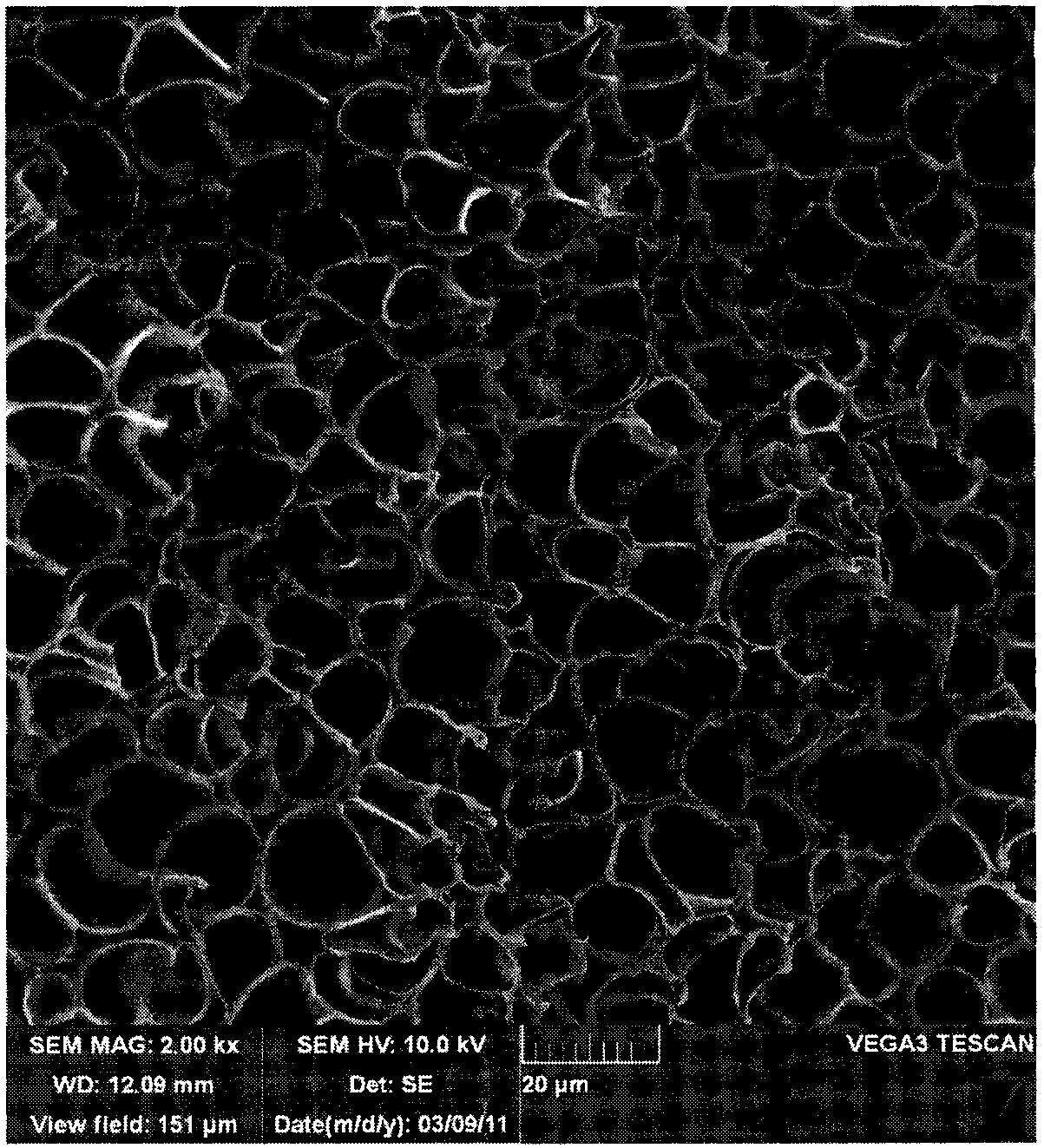

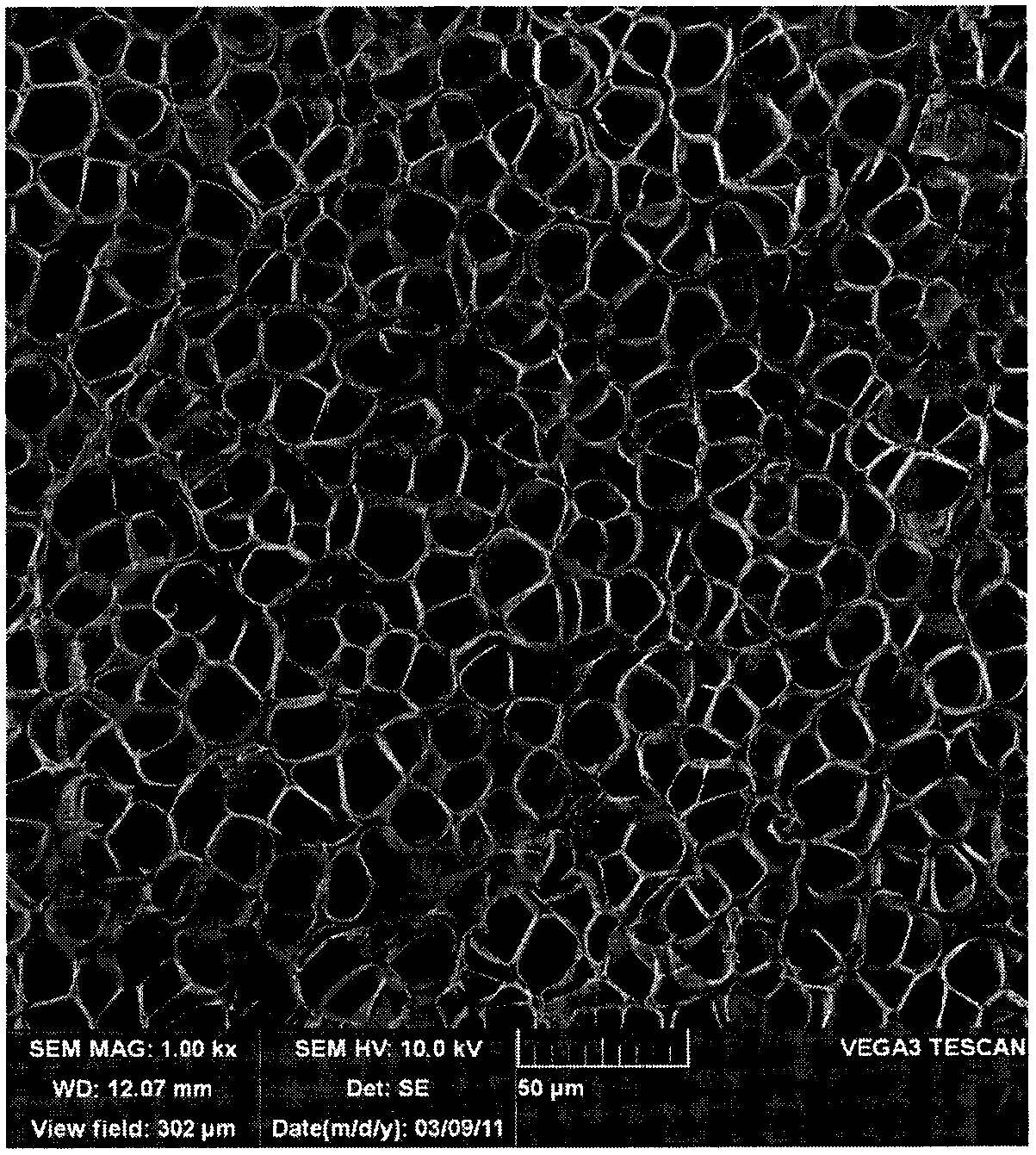

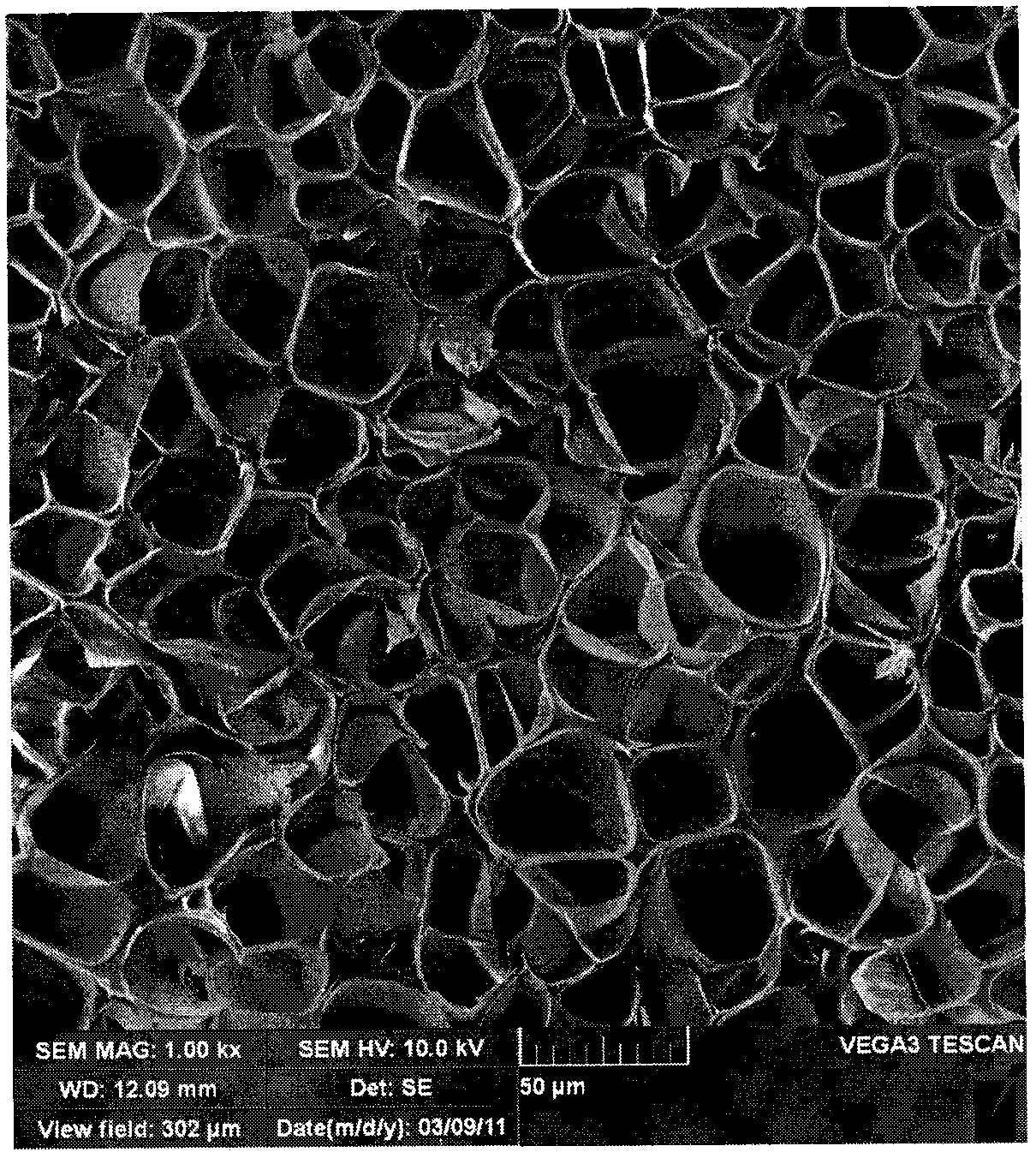

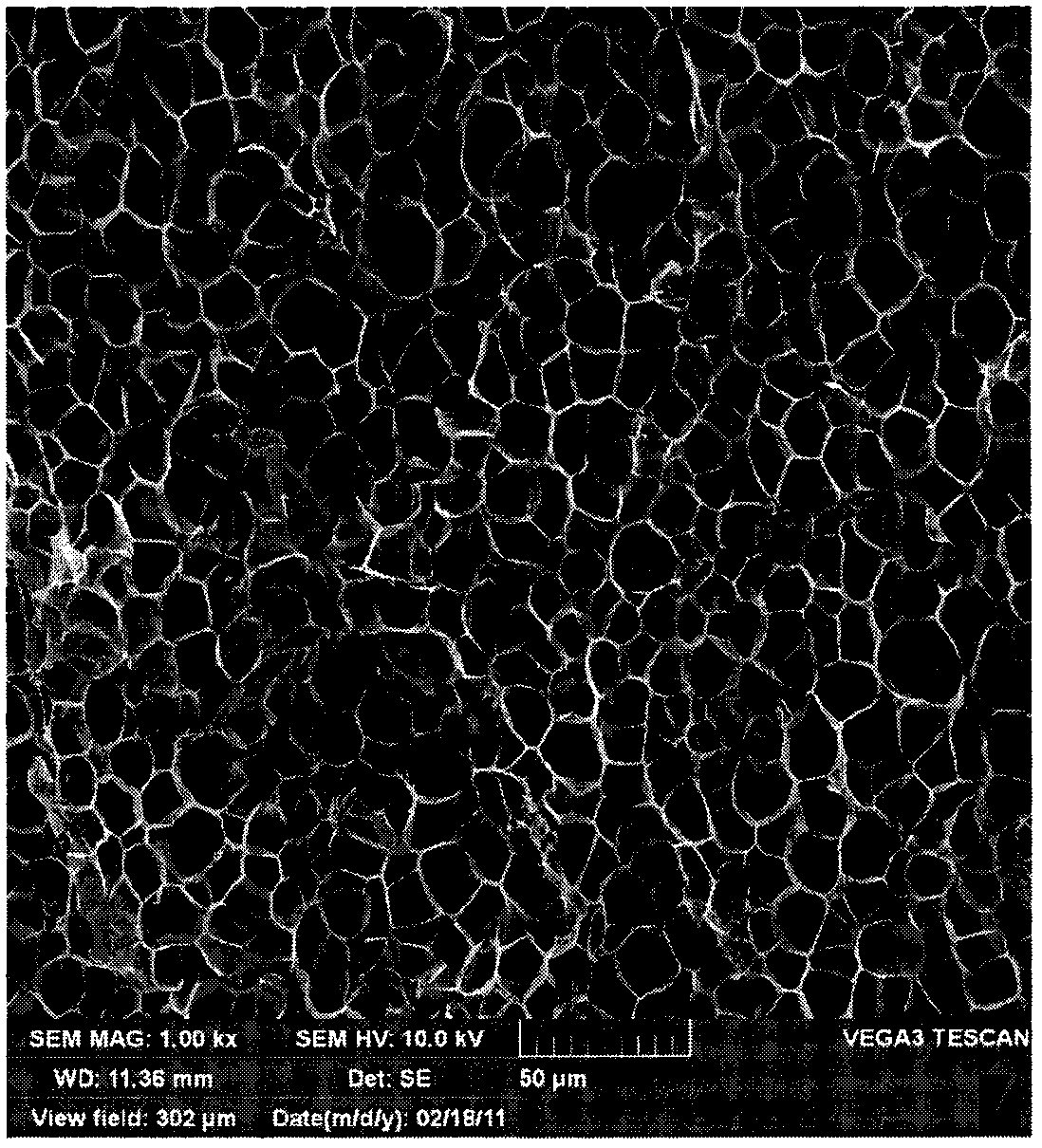

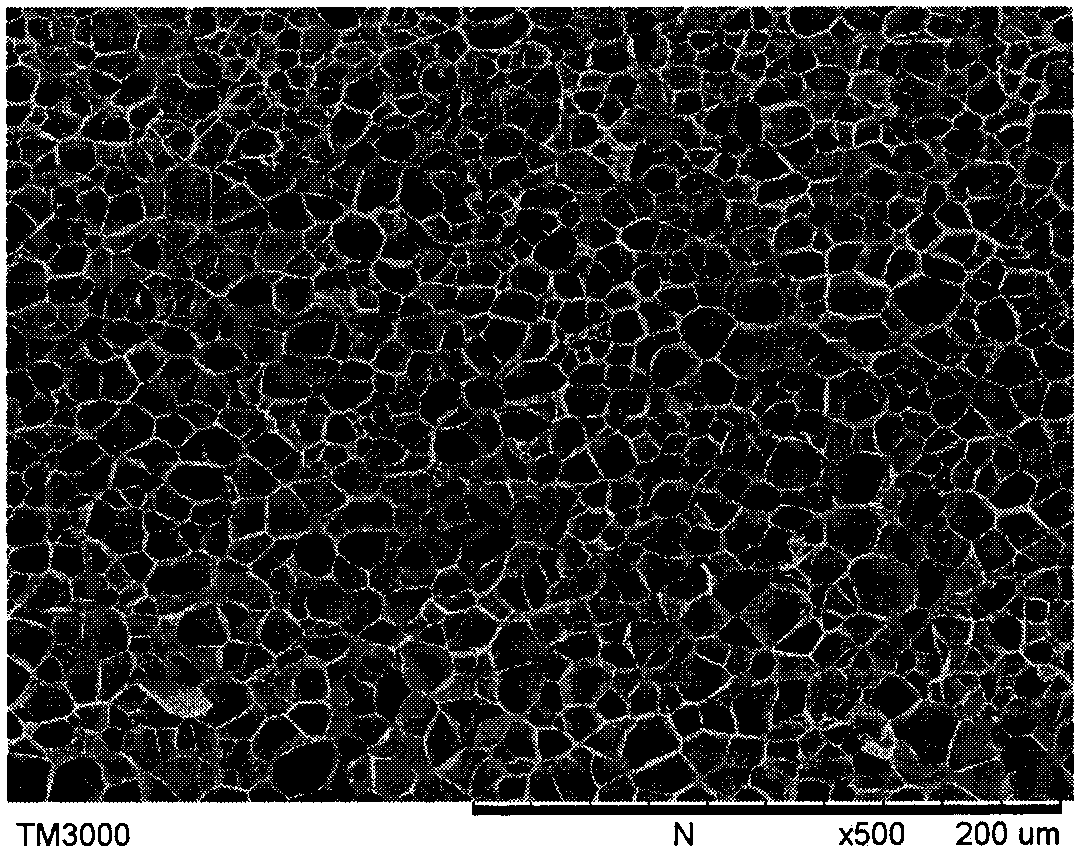

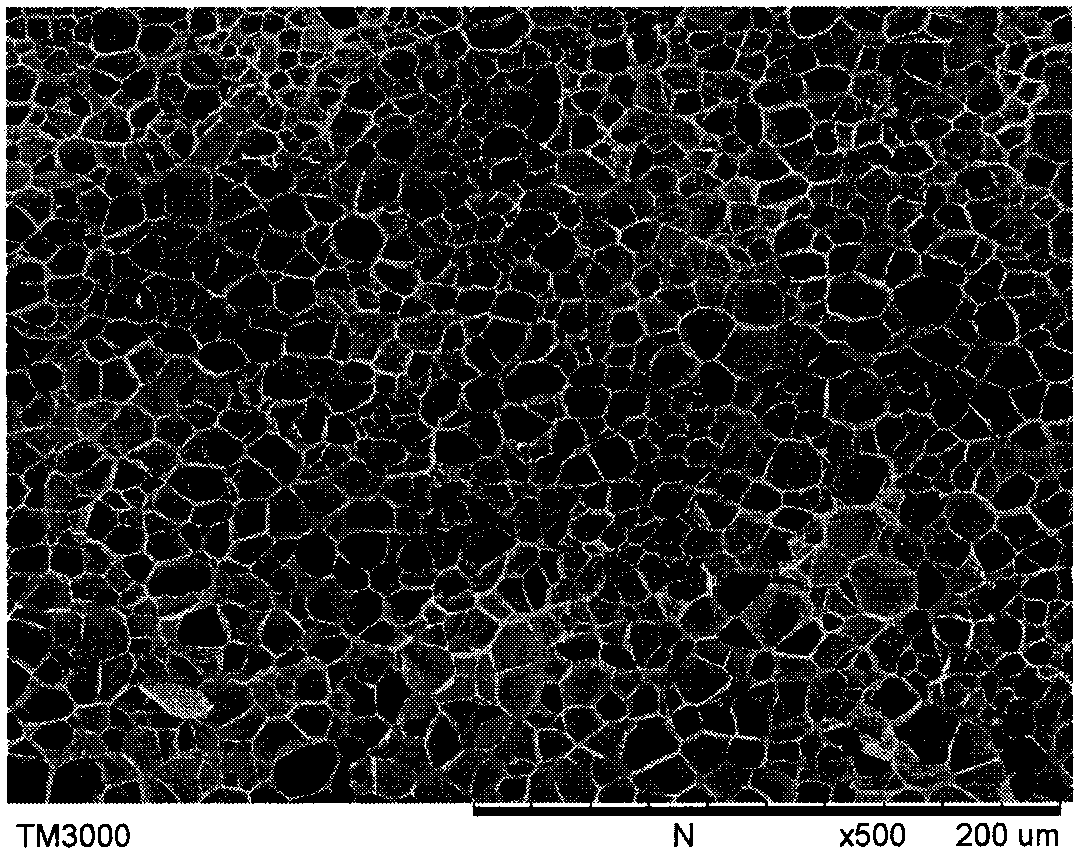

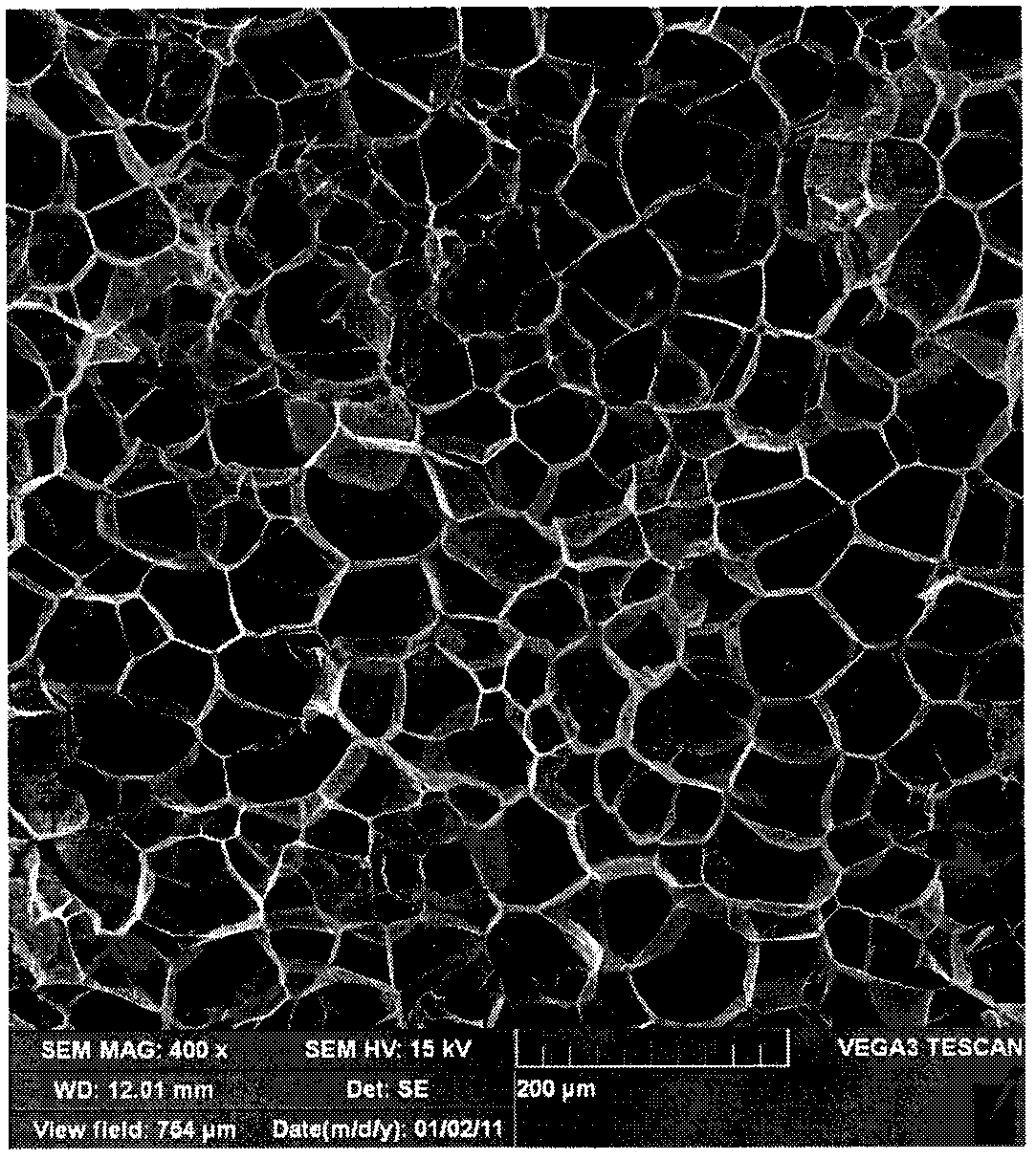

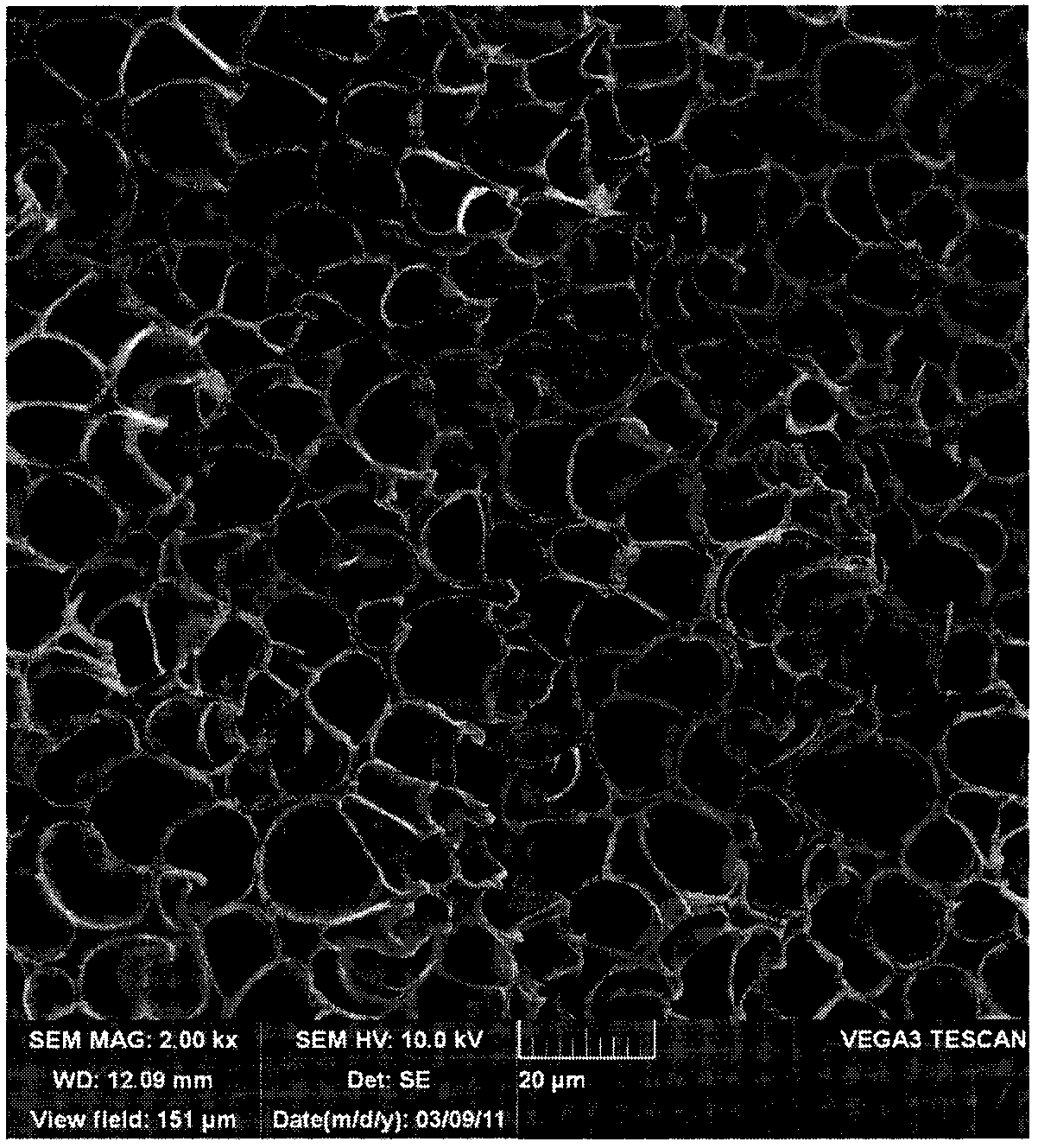

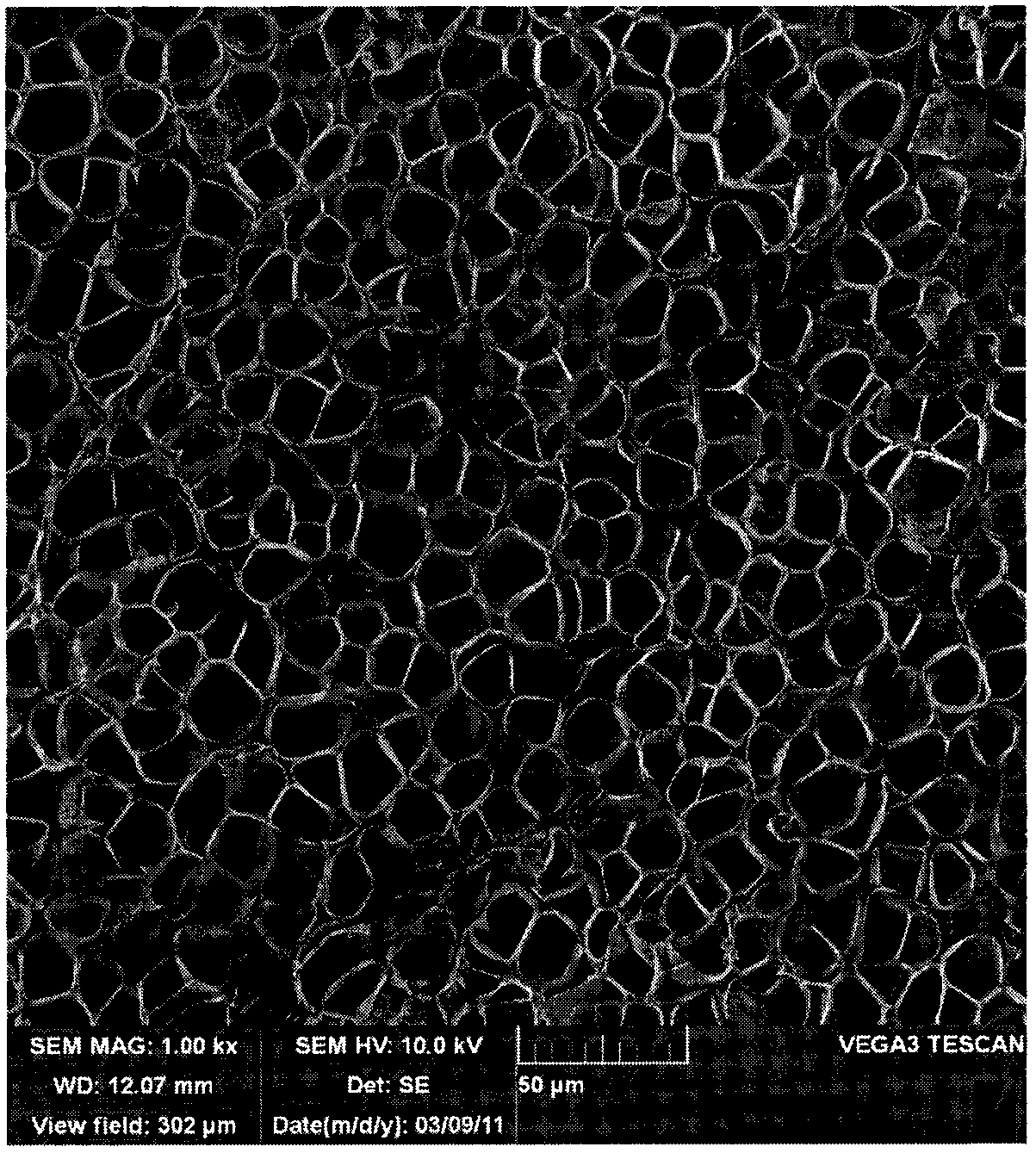

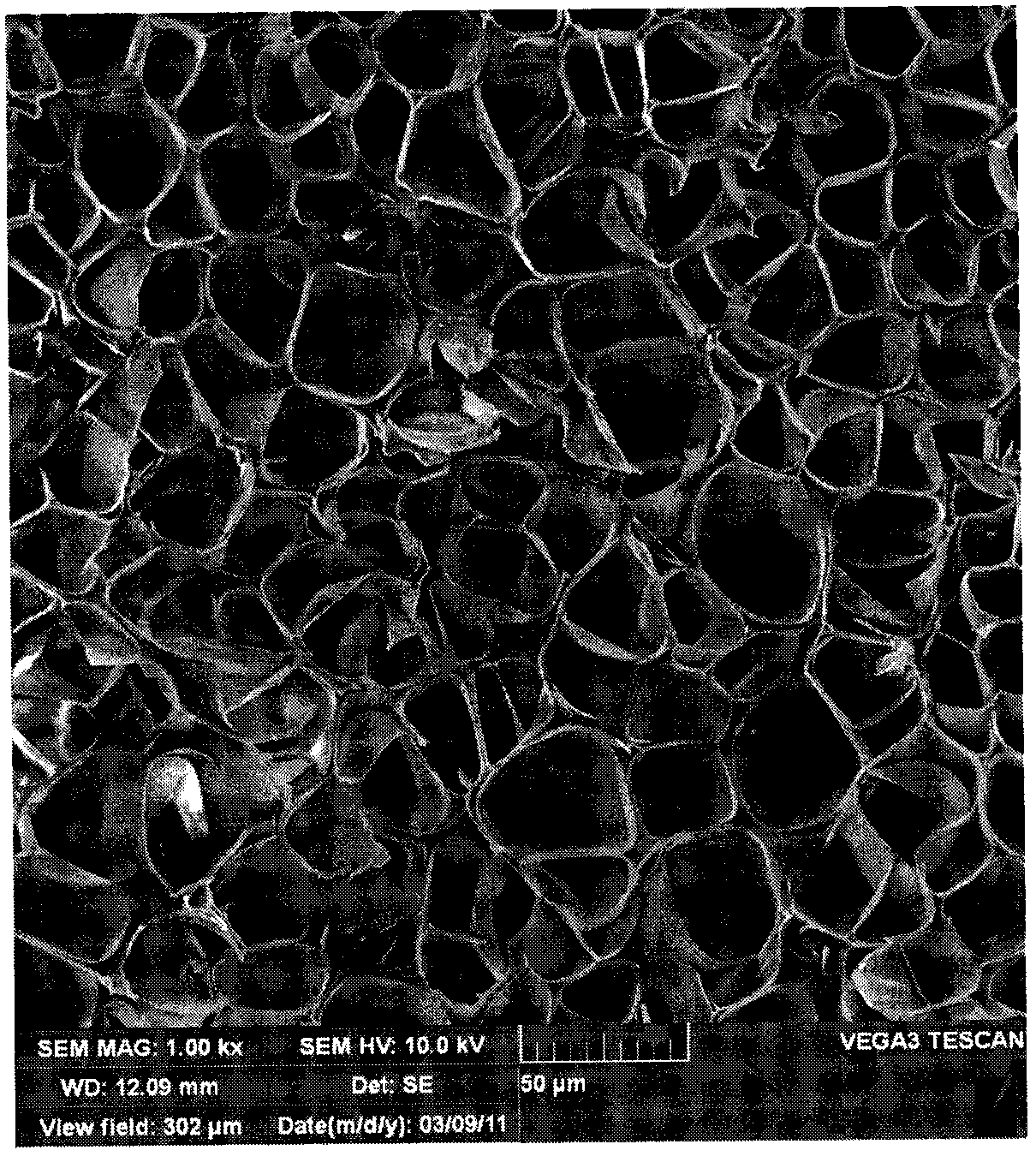

Process for producing ordered porous anodic alumina form

The present invention discloses one kind of ordered porous anode oxidized alumina template preparing process. Compared with available technology, the said process has the advantages of capacity one preparing great area highly ordered nanometer template, high template success rate and high template quality including raised nanometer pore arrangement orderliness, pore size homogeneity, depth uniformity and porosity.

Owner:DONGGUAN UNIV OF TECH

Method for preparing polyimide foam by polyether couple precuror process

The invention discloses a method to prepare polyimide foam in the course that polyether is coupled with precursor. It makes aromatic dianhydride react with monohydroxy polyether and small molecular alcohol at 60-90 deg.C, to obtain aromatic diacid diester solution, then adds in aromatic diamine and small molecular ether to fully react at 50-80 deg.C, adds in foam stabilizer and strengthener; eliminates superfluous alcohol and small molecular ether to obtain polyether-coupled monomer precursor powder; places the powder in mould, preheats and foams at 70-180 deg.C, and solidifies at high temperature of 200-450 deg.C to obtain the polyimide foam which has closed cell structure and density 0.01-0.5g / cu cm.

Owner:ZHEJIANG UNIV

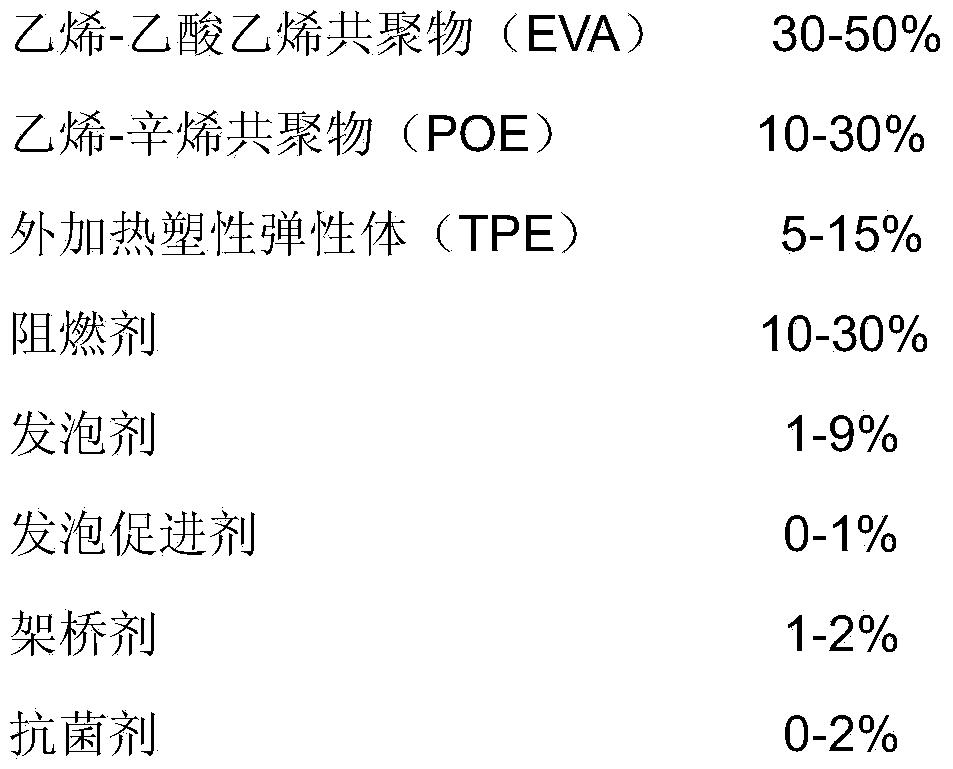

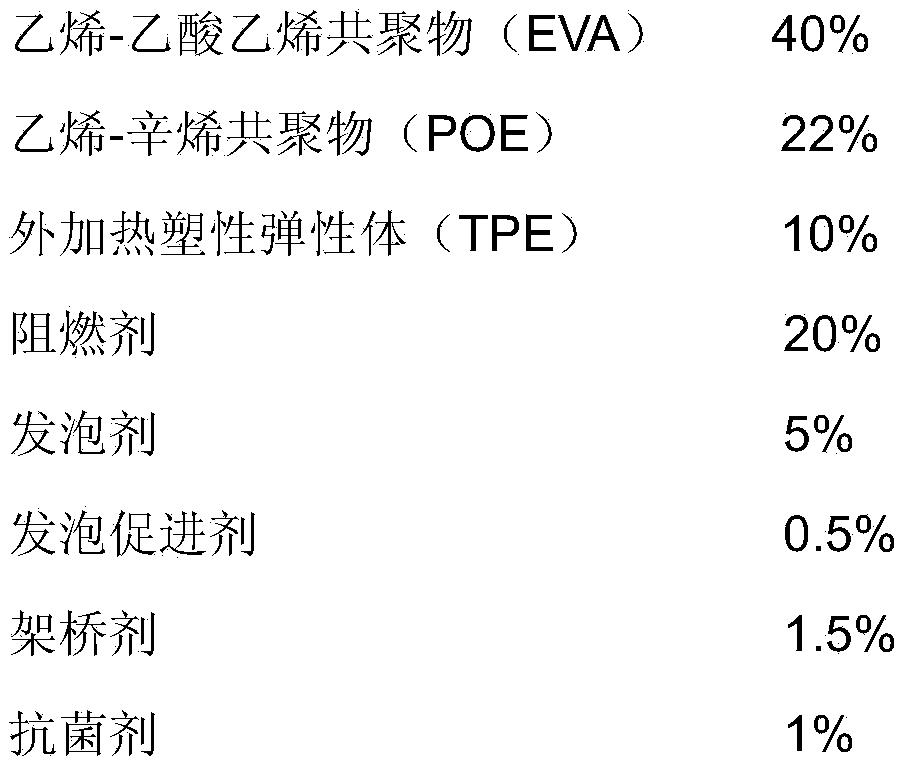

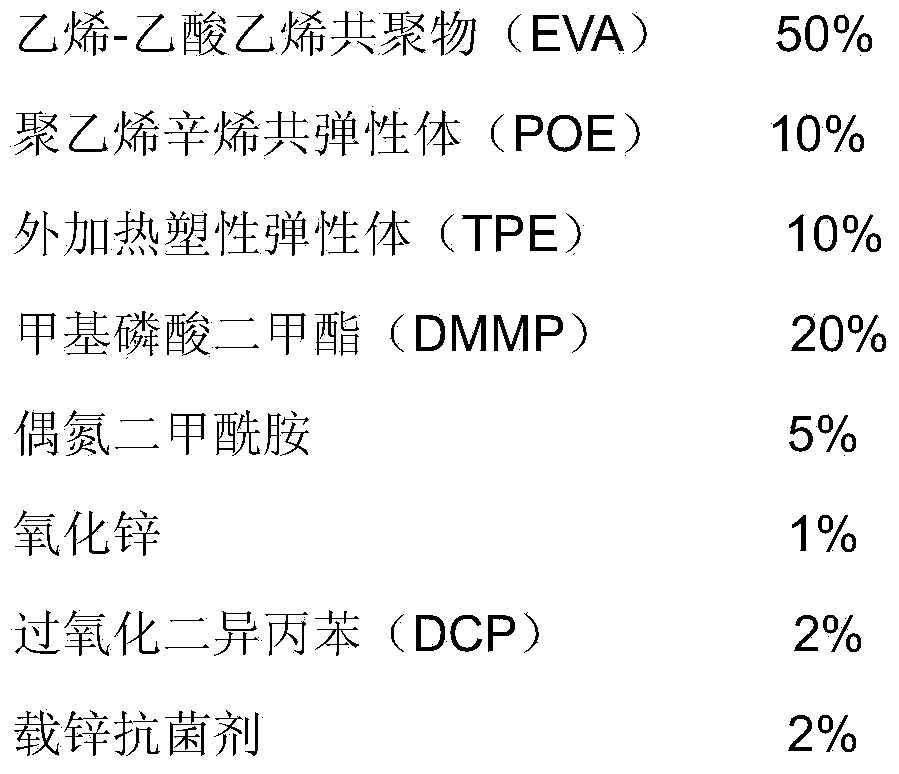

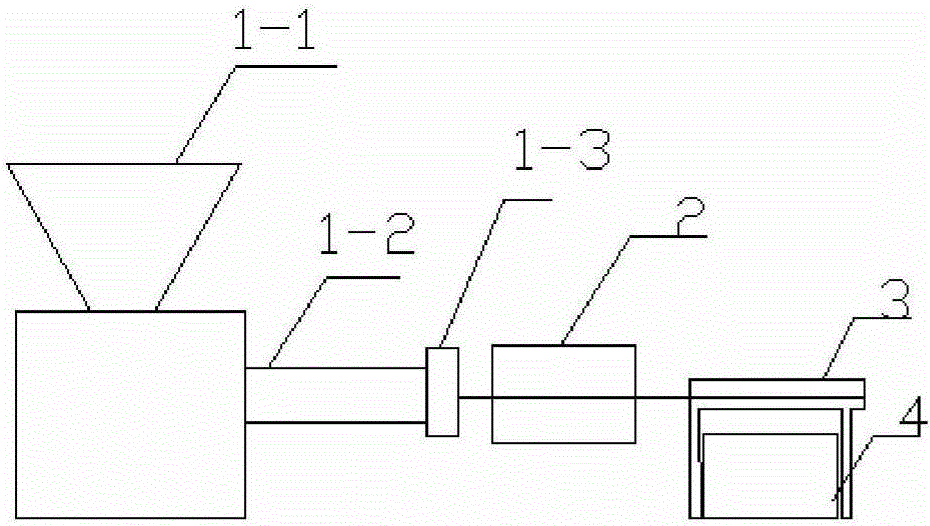

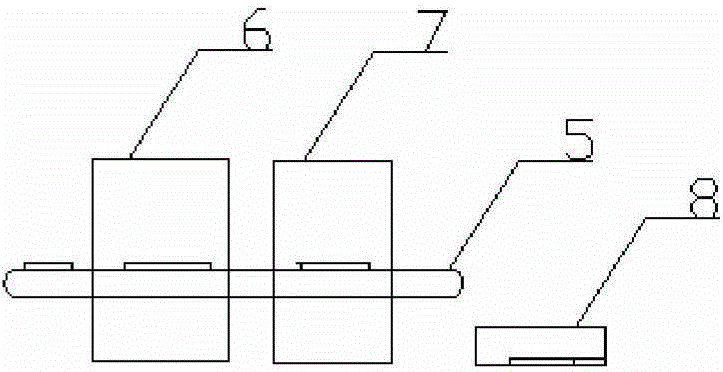

Elastic material and application thereof

The invention provides an EVA (ethylene-vinyl acetate) foamed elastic material and application thereof. The elastic material is prepared by mixing and foaming the following components in percentage by weight: 30-50% of EVA copolymer, 10-30% of ethylene-octylene copolymer, 5-15% of additional thermoplastic elastomer, 10-30% of flame retardant, 1-9% of foaming agent, 0-1% of foaming promoter, 1-2% of bridging agent and 0-2% of antimicrobial agent. The elastic material provided by the invention has shape memory function and slow-rebound performance, and can be used for pillows, mattresses, automobile mats and the like in household or medical recovery care products.

Owner:SHANGHAI YUQIANG TRADE

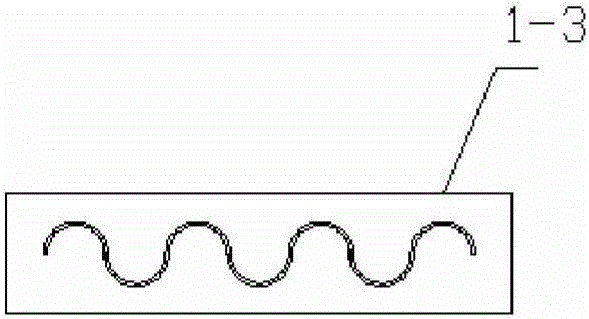

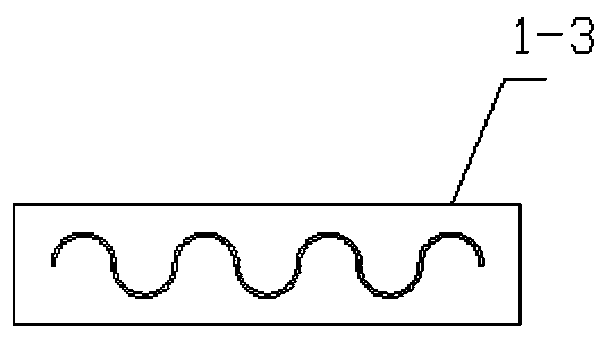

Plate-shaped corrugated membrane diaphragm having uniform aperture and preparation method thereof

The invention relates to a plate-shaped corrugated membrane diaphragm having uniform aperture and a preparation method thereof, which belong to the technical field of sewage processing. According to the invention, a plate-shaped membrane having a corrugated shape is employed, and the method comprises a high-energy radiation etching step, a PET extrusion moulding step and a marking radiation pore-forming step; the PET extrusion moulding step employs a PET extrusion form to form a heterotype diaphragm, a nuclear track membrane moulding technology step is used on the heterotype diaphragm for completing the moulding of the aperture; and the plate-shaped corrugated membrane diaphragm having uniform aperture is prepared. The plate-shaped corrugated membrane diaphragm having uniform aperture has the advantages that PET extrusion moulding and the marking radiation pore-forming technology are combined, the corrugated plate-shaped membrane is obtained through PET extrusion, diaphragm applying while operation can be effectively prevented, the hydrophilic performance of a PET material is stronger than that of PVDF, good aperture uniformity can be guaranteed by the radiation pore-forming technology, and better effect of the plate-shaped corrugated membrane can be obtained through a plurality of effects.

Owner:BEIJING ORIGIN WATER FILM TECH

Preparation method of polyvinyl alcohol microcellular foam material

InactiveCN107722332AShort saturation timeImprove foaming efficiencyMaterials preparationPVA - Polyvinyl alcohol

The invention relates to a method for preparing a polyvinyl alcohol microcellular foam material by utilizing the supercritical fluid technique. A polyvinyl alcohol composition is put in a device filled with a specific supercritical fluid at the specific soaking temperature at the soaking pressure, the heat and the pressure are preserved and maintained for a specific period of time, then the heat and the pressure are preserved and maintained for a specific period of time at the higher saturation temperature and higher saturation pressure of the supercritical fluid, the pressure is relieved at the specific decompression rate, and the polyvinyl alcohol microcellular foam material is obtained. The method is an efficient polyvinyl alcohol microcellular foam material preparation method suitablefor industrial production.

Owner:NINGBO UNIV

Preparation method for polycarbonate microcellular foaming material

The invention relates to a method for preparing a polycarbonate microcellular foaming material through a supercritical fluid technology. The method comprises the following steps: putting a polycarbonate material into a device with a specific wetting temperature and wetting pressure of a specific supercritical fluid, and preserving the heat and keeping the pressure for specific time; preserving theheat and keeping the pressure for specific time with a relatively high saturation temperature and relatively high critical fluid saturation pressure, and releasing pressure with a specific pressure releasing rate, thereby obtaining the polycarbonate microcellular foaming material. The method is a method which is suitable for industrially producing and efficiently preparing the polycarbonate microcellular foaming material.

Owner:宁波致微新材料科技有限公司

Production method of Al-Mg hydrotalcite composite polystyrene multi-component copolymerization ion exchange resin

InactiveCN106238011AImprove heat resistanceImprove stress resistanceOther chemical processesWater contaminantsResin microsphereSilanes

The invention discloses a production method of Al-Mg hydrotalcite composite polystyrene multi-component copolymerization ion exchange resin. The method comprises the concrete steps of water phase and oil phase preparation, composite resin microsphere preparation and ion exchange resin synthesis, wherein a resin microsphere framework is prepared from styrene, methyl methacrylate and vinyl trimethoxy silane through crosslinking. The polystyrene multi-component copolymerization ion exchange resin provided by the invention has the advantages that the high-temperature resistant performance is good; the chemical resistant stability is high; the application range is wide; meanwhile, the mechanical intensity is high; the pore diameter uniformity is good; the ion exchange volume is high; the adsorption performance on various organic contaminants such as N, P and dyestuff is good; the production method is applicable to organic waste water treatment.

Owner:ANHUI WANDONG CHEM

Production method of nano cellulose composite polystyrene multipolymer cation exchange resin

InactiveCN106279486AImprove heat resistanceImprove stress resistanceCation exchanger materialsResin microspherePolystyrene

The invention discloses a production method of a nano cellulose composite polystyrene multipolymer cation exchange resin. The method comprises the following steps: preparing a water phase and an oil phase, preparing composite resin microspheres and synthesizing the ion exchange resin, wherein the resin microsphere framework is prepared by crosslinking styrene, methyl methacrylate and vinyltrimethoxysilane. The polystyrene multipolymer cation exchange resin has the advantages of favorable high-temperature resistance, favorable chemical resistance stability, wide applicability, high mechanical strength, favorable pore size uniformity and high ion exchange capacity, especially has favorable adsorbability for heavy metal pollutants, and is suitable for treatment of heavy metal wastewater.

Owner:ANHUI WANDONG CHEM

Preparation method of microporous foamed polypropylene reflecting film

The invention relates to a preparation method of a microporous foamed polypropylene reflecting film. The preparation method comprises steps as follows: a polypropylene sheet material is placed in a device with specific infiltrating temperature and infiltrating pressure of specific supercritical fluid, temperature preservation and pressure maintaining are performed for specific time, then temperature preservation and pressure maintaining are performed for specific time at higher saturation temperature and under higher supercritical fluid saturation pressure, pressure is released at a specific pressure release rate, a microporous foamed polypropylene material can be obtained, and the microporous foamed polypropylene reflecting film is obtained through splitting. The method is suitable for industrial production and can be used for preparing the microporous foamed polypropylene reflecting film efficiently.

Owner:宁波致微新材料科技有限公司

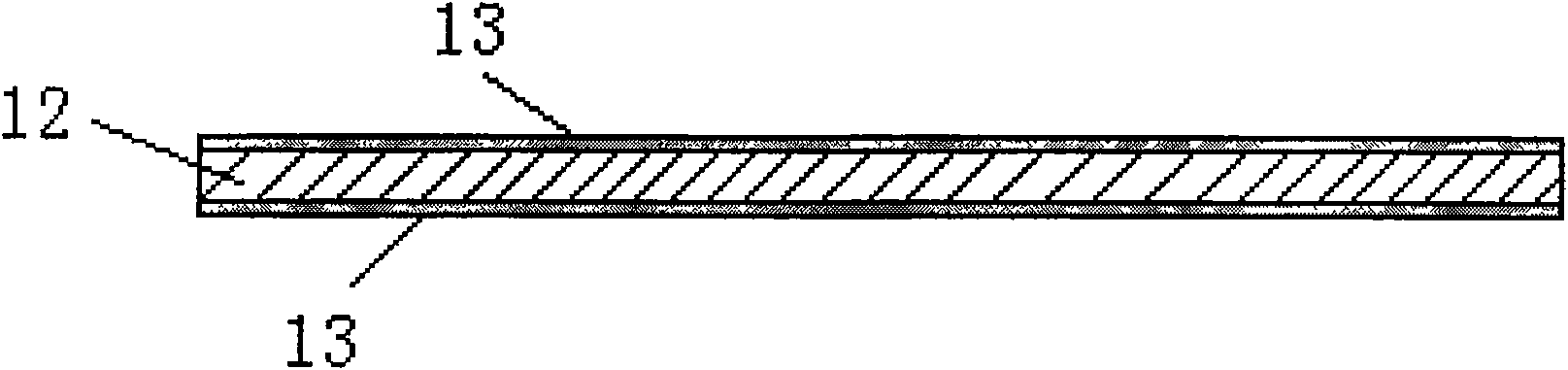

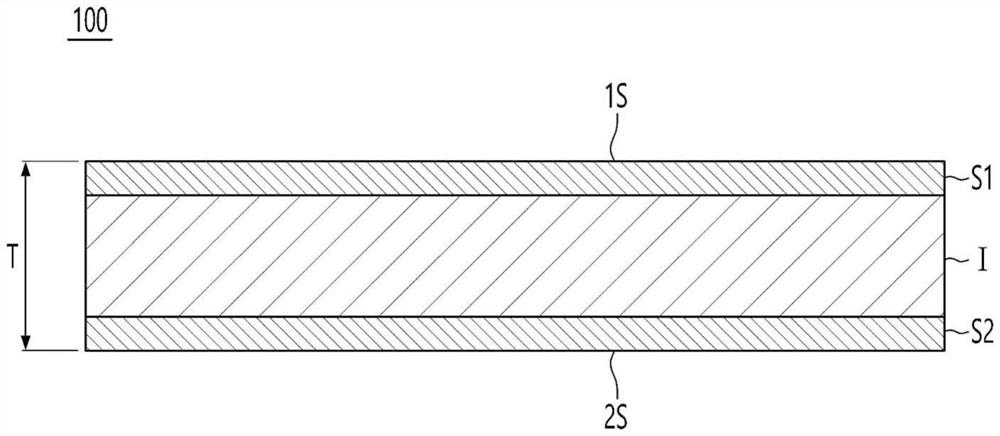

Reinforced microporous filter membrane and method and device for preparing the same

InactiveCN100586537CHigh strengthSmall filter resistanceSemi-permeable membranesPolymer sciencePolymer resin

The present invention provides an enhanced millipore filtering film and a method, device for preparing, the enhanced millipore filtering film includes a non-woven fabric as substrate, employing casting wipe way, casting film liquid is applied on the front and the back surfaces of the non-woven fabric, two layer film is formed by gelatin, characterized in that the thickness of the non-woven fabricis 30-120 micron, planar density of the non-woven fabric is 30-100g / m2, thickness of each film layer is 5-10 micron; casting film liquid in two film layer is composed by mixing a polymer resin, an organic solvent and an additive; parts by weight of the polymer resin in the casting film liquid, parts by weight of the organic solvent : parts by weight of the additive is 5-40:40-90: 0.5-50. The enhanced millipore filtering film of the invention is applied in the sampling monitor or filter of alpha radioaerosol under the high radon environment.

Owner:BEIJING RADIATION APPL RES CENT

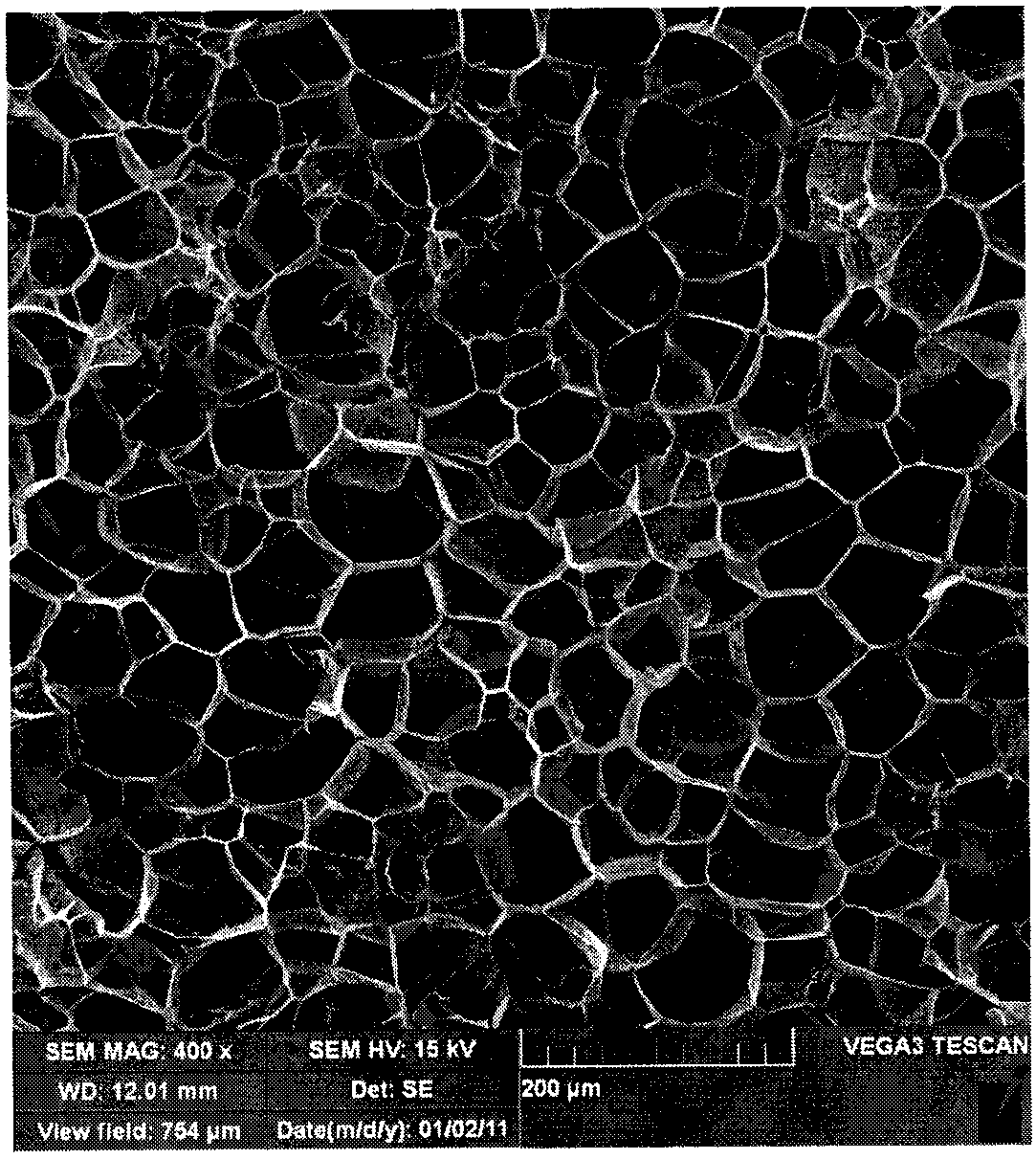

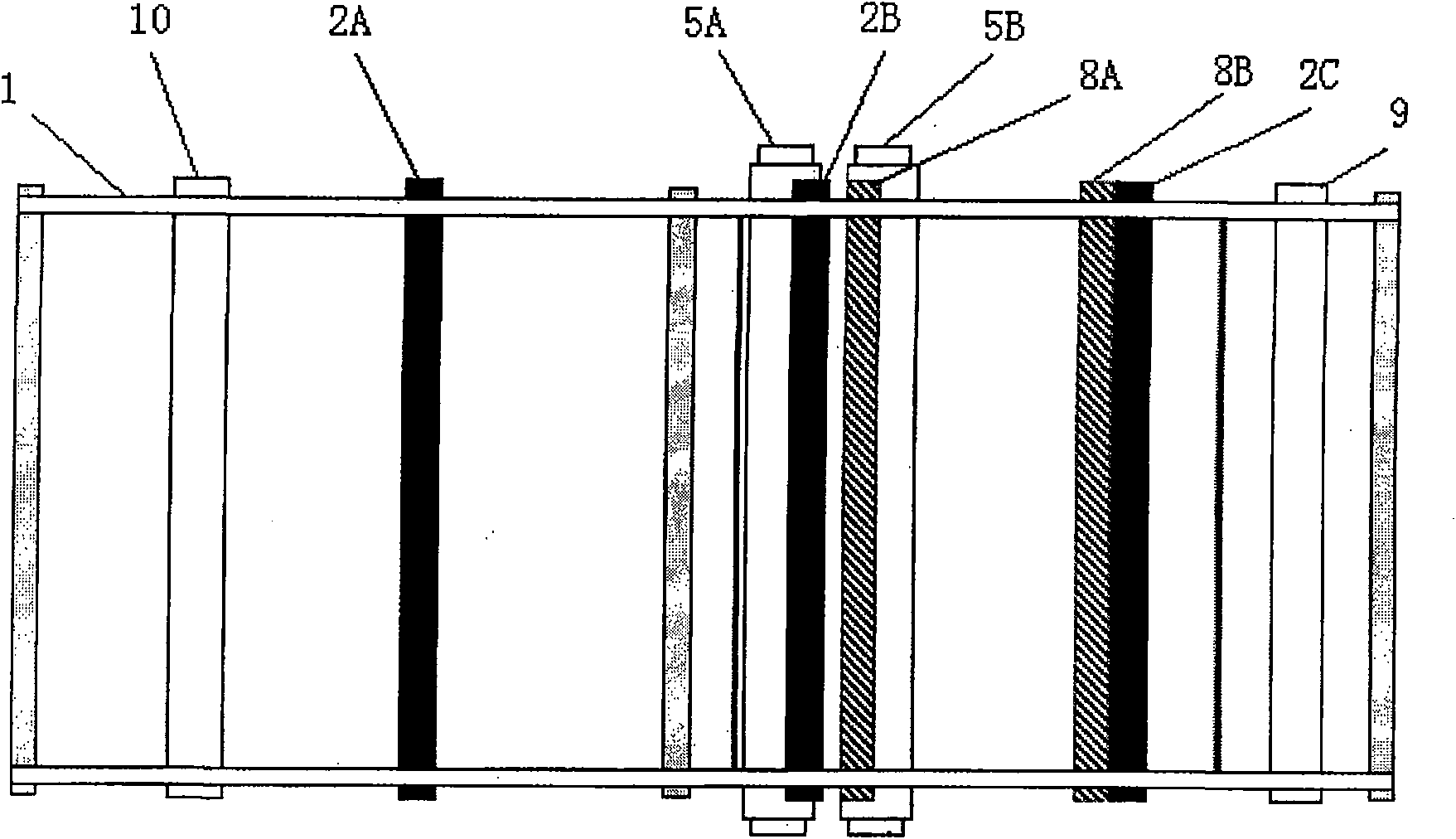

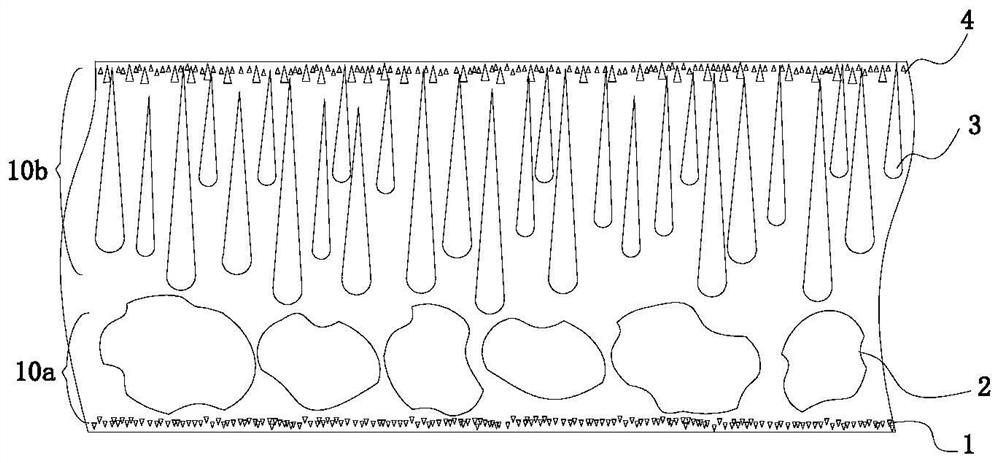

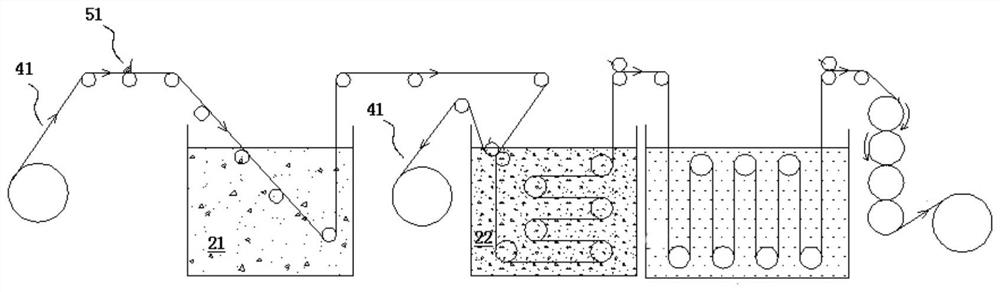

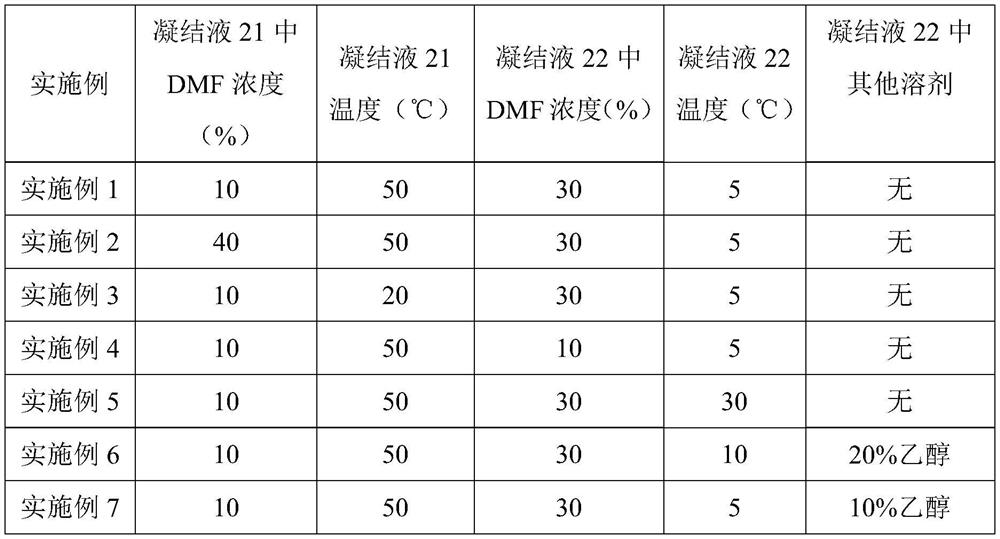

Chemical mechanical polishing pad and preparation method thereof

PendingCN114701105ASlow down the speed of two-way diffusionGood followabilityGrinding devicesLapping toolsTotal thicknessPolymer chemistry

The invention relates to a chemical mechanical polishing pad and a preparation method thereof. According to the chemical mechanical polishing pad, polyurethane resin slurry is used and smeared on a film forming base material coated with a release agent, and different hole structures are coagulated on the two sides of a coagulated film in two steps in a two-section coagulation mode. In the process of condensation and pore forming, the concentration and temperature of two sections of condensation liquid are controlled, so that pores of two different pore structures are formed in the same condensation film at the same time, the diameter of finger-shaped pores which account for at least 15% of the total thickness of the condensation film from the surface layer to the inside is not larger than 25 microns, and the finger-shaped pores formed in the second layer side are high in pore diameter uniformity, small in pore diameter and large in abradable thickness; the service life of the polishing pad is prolonged; the sponge-shaped holes are formed in the side of the first layer, the thickness of the sponge-shaped holes accounts for one third or more than one third of the total thickness of the condensation film, the followability of a to-be-polished object is good, flexible support is provided, and the surface planarization degree of the to-be-polished object is improved.

Owner:宁波赢伟泰科新材料有限公司 +1

Production method of polystyrene multi-component copolymerization ion exchange resin for removing anionic dye

InactiveCN106243262AImprove heat resistanceImprove stress resistanceWater contaminantsWater/sewage treatment by ion-exchangeResin microsphereSilanes

The invention discloses a production method of polystyrene multi-component copolymerization ion exchange resin for removing anionic dye. The method comprises the specific steps of preparation of a water phase and an oil phase, preparation of composite resin microspheres and synthesis of the ion exchange resin, wherein a resin microsphere framework is prepared by crosslinking styrene, methyl methacrylate and vinyl trimethoxy silane. The polystyrene multi-component copolymerization ion exchange resin has the good high temperature resistance and chemical stability resistance and is wide in application range, high in mechanical strength, good in pore size uniformity, high in ion exchange capacity, especially good in adsorptive property on anionic dye contaminants and suitable for treatment of wastewater containing the anionic dye.

Owner:ANHUI WANDONG CHEM

Preparation method for applying urea and polyethylene glycol blend to bioactive glass bone repair material pore-forming process

InactiveCN103787581AConducive to solidificationAvoid looseProsthesisTemperature controlBioactive glass

The invention discloses a preparation method for applying a urea and polyethylene glycol blend to a bioactive glass bone repair material pore-forming process. The preparation method comprises the following steps: mixing powdery bioactive glass, urea and polyethylene glycol according to a ratio; pressing and molding; carrying out heat treatment in a programmed temperature control box type resistance furnace at 20-850 DEG C for 240-480 minutes to prepare the inorganic amorphous-state bioactive glass bone repair material. According to the preparation method, compared with a process of independently taking the urea as a pore-forming agent, the urea and polyethylene glycol blend is used as the pore-forming agent; the calcined bioactive glass material is high in porosity and good in pore diameter uniformity and the shape of the material is not easy to deform.

Owner:邝大军

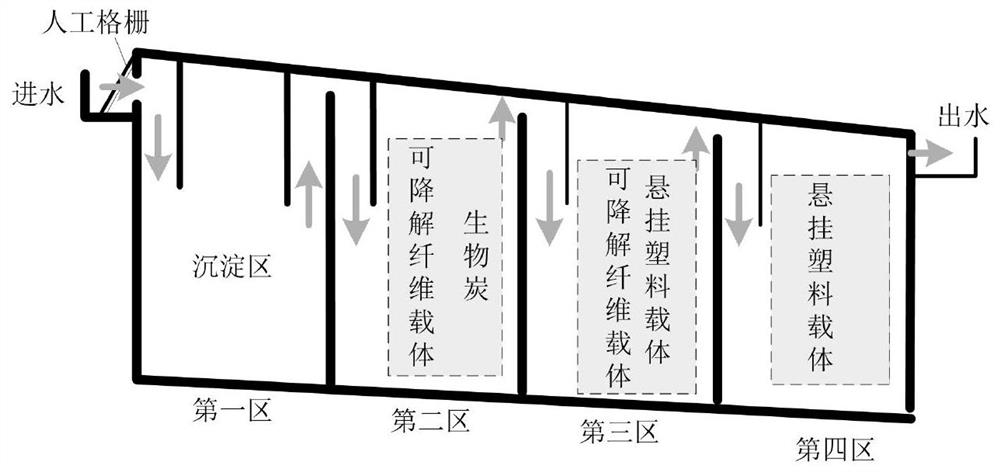

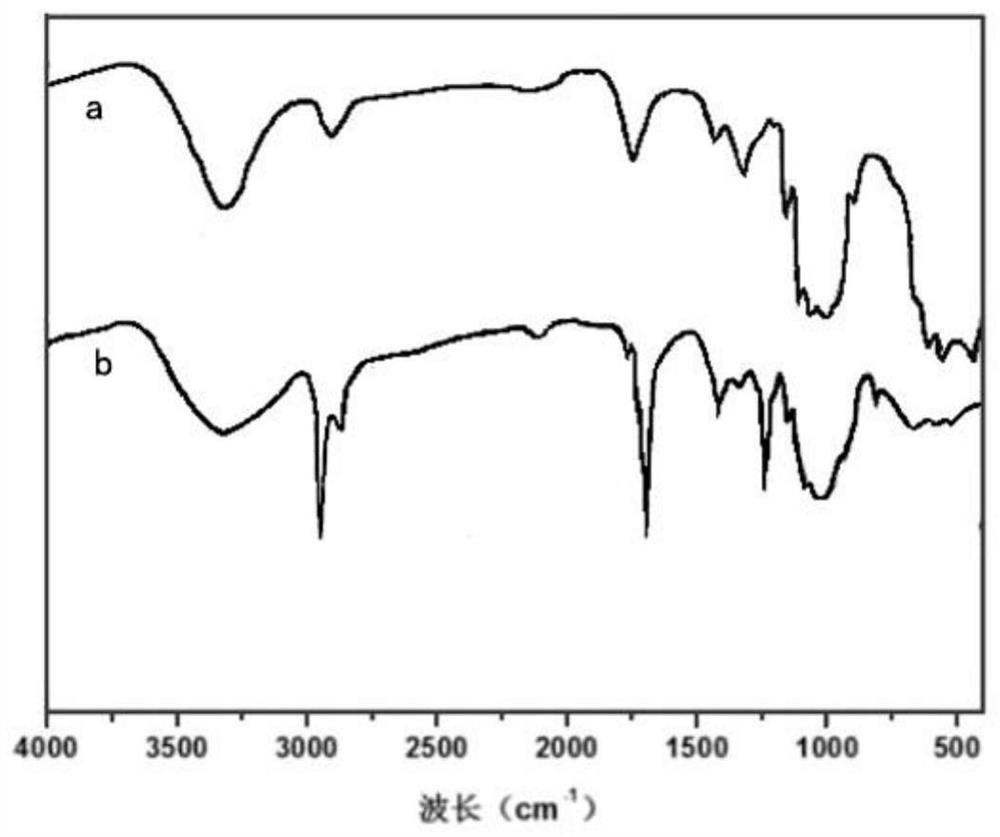

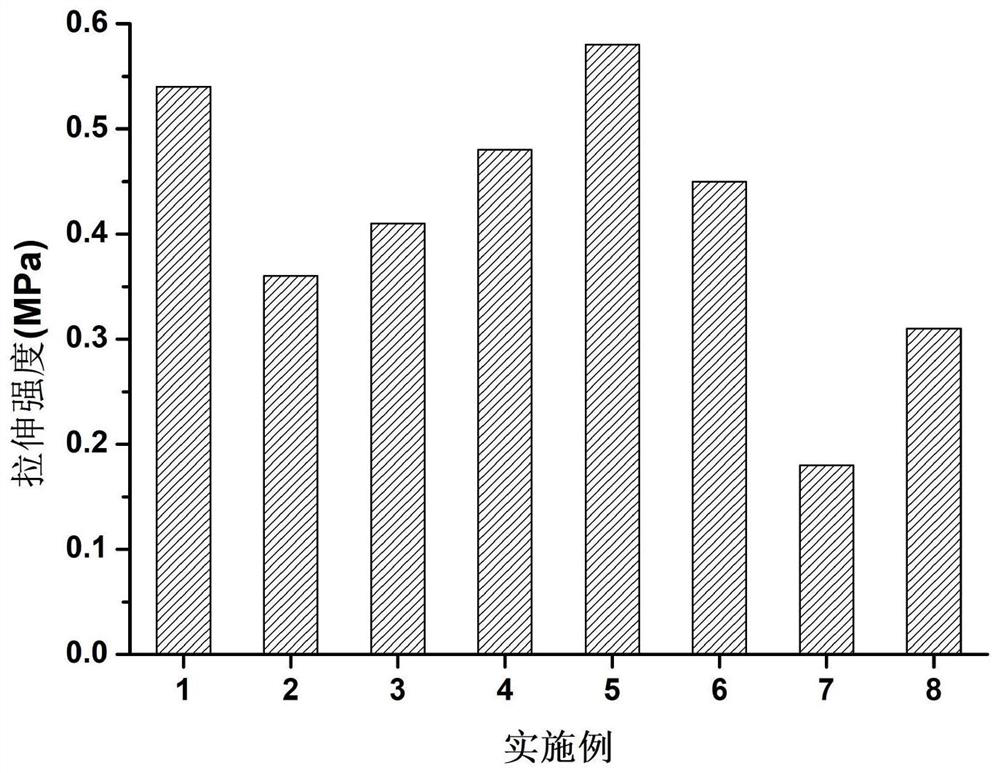

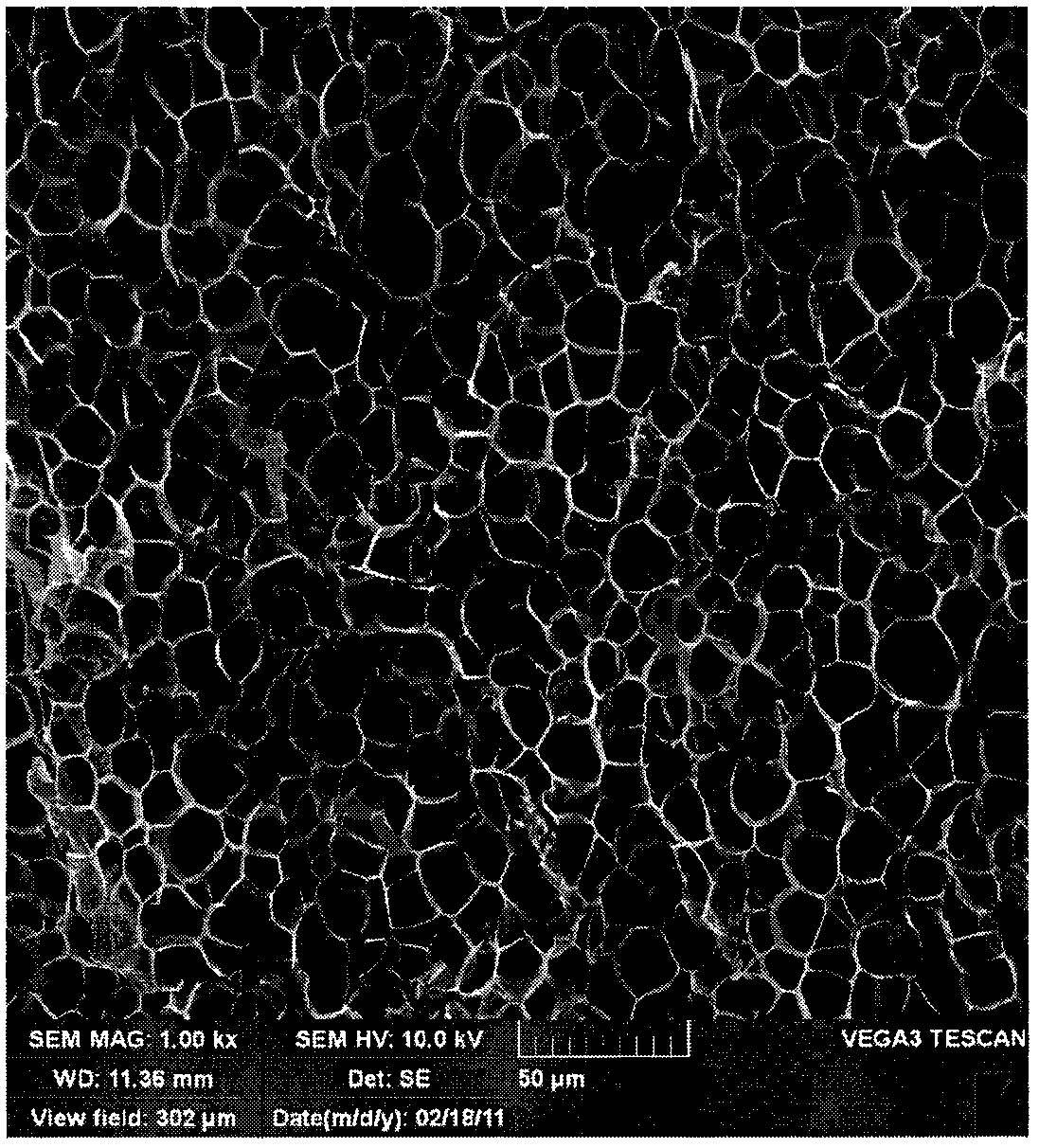

Method for treating polluted water body by synchronous nitrification and denitrification biological carrier coupling system

ActiveCN112744916AAperture small noUniformity NoneWater contaminantsTreatment with aerobic and anaerobic processesCelluloseBiofilm

The invention discloses a method for treating a polluted water body by a synchronous nitrification and denitrification biological carrier coupling system. A construction method of the synchronous nitrification and denitrification biological carrier coupling system comprises the following steps: 1) preparing a degradable cellulose carrier and biochar; 2) constructing a biological membrane device; 3) arranging the degradable cellulose carrier, the biochar and a conventional carrier in the biological membrane device, and adding functional bacteria to form the synchronous nitrification and denitrification biological carrier coupling system. The synchronous nitrification and denitrification biological carrier coupling system can quickly enrich functional microorganisms in a water body which is mainly polluted by ammonia nitrogen and nitrate nitrogen by utilizing the strong adsorption performance of a degradable cellulose carrier slow-release carbon source and biological carbon, so that an efficient denitrification effect is achieved.

Owner:ZHEJIANG OCEAN UNIV

Preparation method of polypropylene microcellular foaming material

InactiveCN107718408AShort saturation timeImprove foaming efficiencyPolypropyleneTemperature and pressure

The invention relates to a method of preparing a polypropylene microcellular foaming material by means of supercritical fluid technology. The method comprises the following steps of: putting a polypropylene material in a device with a special infiltration temperature and an infiltration pressure of a special supercritical fluid; keeping the temperature and pressure for a special time; then keepingthe temperature and the pressure for a special time at a relatively high saturation temperature and a relatively high supercritical fluid saturation pressure; and relieving the pressure at a specialpressure-relieving rate to obtain the polypropylene microcellular foaming material. The method is the method which is suitable for industrial production and prepares the polypropylene microcellular foaming material efficiently.

Owner:宁波致微新材料科技有限公司

Preparation method of micro-pore foaming polycarbonate reflecting film

The invention relates to a preparation method of a micro-pore foaming polycarbonate reflecting film. The preparation method comprises the following steps: putting a polycarbonate sheet material into adevice with specific wetting temperature and wetting pressure of specific supercritical fluid and keeping temperature and keeping pressure for specific time; then keeping temperature and keeping pressure for specific time under relatively high saturated temperature and relatively high supercritical fluid saturated pressure; releasing pressure at a specific pressure releasing speed to obtain a polycarbonate micro-pore foaming material; and splitting the polycarbonate micro-pore foaming material to obtain the micro-pore foaming polycarbonate reflecting film. The method is a method which is suitable for industrially producing and efficiently preparing the micro-pore foaming polycarbonate reflecting film.

Owner:宁波致微新材料科技有限公司

Textile fabric formaldehyde remover and preparation and application thereof

ActiveCN107142719AIncrease the areaImprove self-cleaning abilityBiochemical fibre treatmentLight resistant fibresAntifungalPorosity

The invention discloses a textile fabric formaldehyde remover and preparation and application thereof. The textile fabric formaldehyde remover is composed of, by weight part, 8-14 parts of nano modified rectorite, 2-5 parts of 1-vinyl imidazole, 1-4 parts of acetoguanamine, 0.2-0.7 part of amidinourea phosphate, 1.2-1.8 parts of antibacterial agent, 0.5-2 parts of aromatics, 0.1-0.4 part of surfactant, 3-8 parts of polyvinyl alcohol and distilled water as balance. The textile fabric formaldehyde remover, which is prepared through reasonable formula and processes, is high in specific surface area and self-cleanliness, and compared with traditional absorbent agent of activated carbon, improves the porosity by more than 55% and prolongs the service life by more than 3 times. Meanwhile, the textile fabric formaldehyde remover obtains excellent anti-static, anti-bacteria, antifungal, radiation-proof and fabric-softening effects and achieves a formaldehyde removing rate within 20 minutes up to 99.2%, thereby being efficient and rapid.

Owner:GUANGDONG QUNHAO CLOTHING

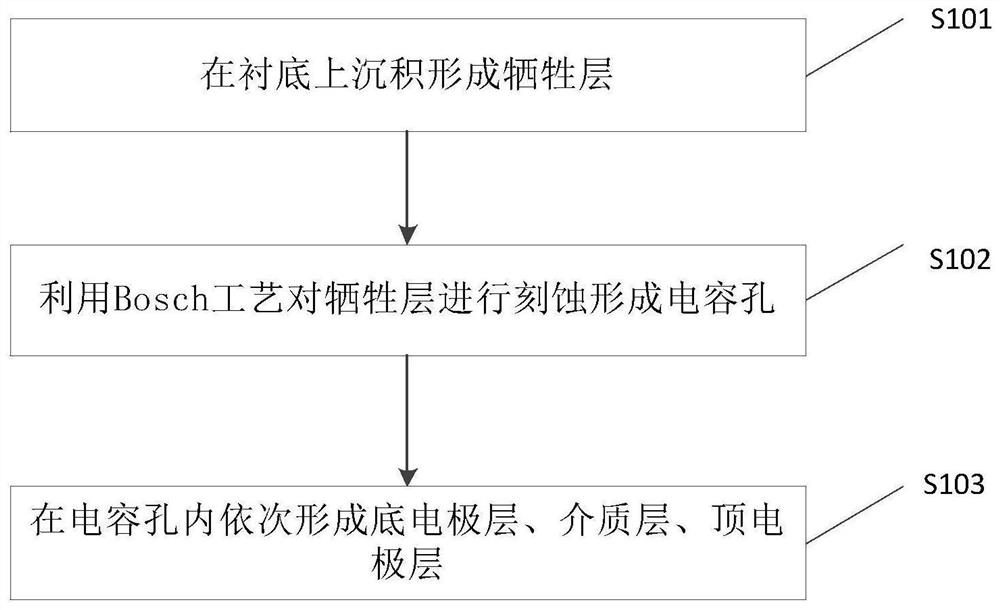

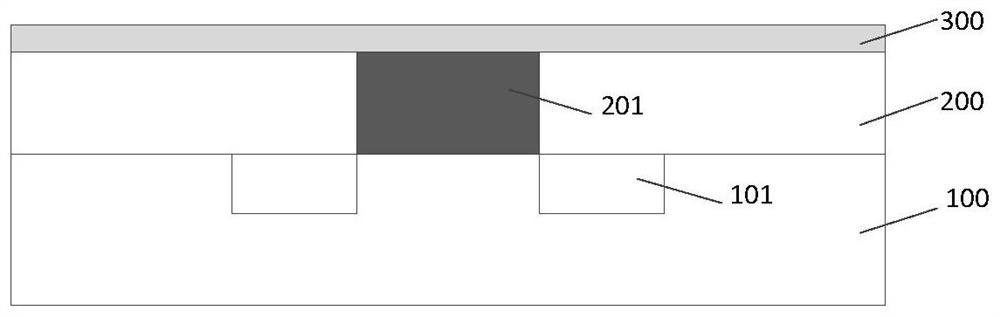

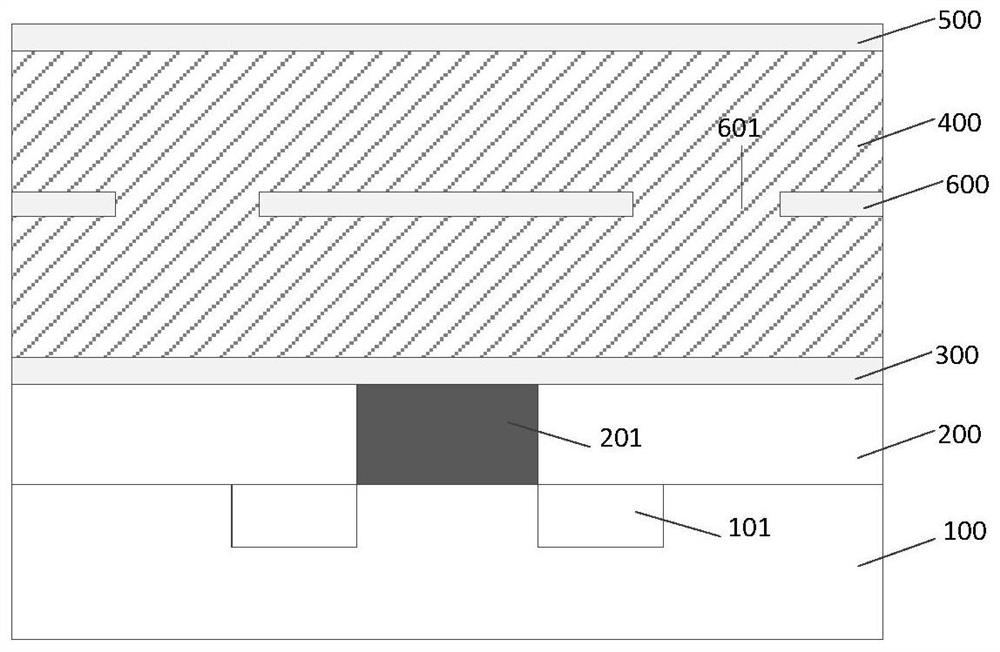

Semiconductor device and manufacturing method thereof

PendingCN113299829AImprove uniformitySimple deposition processTransistorSolid-state devicesPhysicsCapacitance

The embodiment of the invention provides a semiconductor device and a manufacturing method thereof. A sacrificial layer can be deposited on a substrate, the sacrificial layer is etched by using a Bosch process to form a capacitance hole, the side wall of the capacitance hole is in concave-convex alternate change in the longitudinal direction, and a bottom electrode layer, a dielectric layer and a top electrode layer are sequentially formed in the capacitance hole. Due to the fact that the Bosch technology can enable etching to be carried out in the depth direction, formation of the capacitor hole with the high depth-to-width ratio is facilitated, uniformity of the hole diameter of the capacitor hole is improved, the side wall can be protected in the etching process, the concave-convex alternate change characteristic on the side wall is naturally formed in the etching process, doping in the deposition technology is not needed, the deposition technology is simplified, the capacitor area is increased, and a high-performance memory device is obtained on the premise of simplifying the process.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Production method for polystyrene multi-component copolymerization ion exchange resin for treating phenolic wastewater

InactiveCN106188370AImprove heat resistanceImprove stress resistanceWater contaminantsWater/sewage treatment by ion-exchangeResin microsphereSilanes

The invention discloses a production method for polystyrene multi-component copolymerization ion exchange resin for treating phenolic wastewater. The method comprises the specific steps that a water phase and an oil phase are prepared, composite resin microspheres are prepared, and ion exchange resin is synthesized, wherein a resin microsphere framework is formed by cross-linking of styrene, methyl methacrylate and vinyl trimethoxy silane. The polystyrene multi-component copolymerization ion exchange resin has good high-temperature resistance and chemical-resistance stability, and is wide in application range, high in mechanical strength, good in aperture uniformity, high in ion exchange capacity, especially good in adsorption to phenolic pollutants and suitable for treating phenolic wastewater.

Owner:ANHUI WANDONG CHEM

Method for preparing polyimide foam by polyether couple precursor process

The invention discloses a method to prepare polyimide foam in the course that polyether is coupled with precursor. It makes aromatic dianhydride react with monohydroxy polyether and small molecular alcohol at 60-90 deg.C, to obtain aromatic diacid diester solution, then adds in aromatic diamine and small molecular ether to fully react at 50-80 deg.C, adds in foam stabilizer and strengthener; eliminates superfluous alcohol and small molecular ether to obtain polyether-coupled monomer precursor powder; places the powder in mould, preheats and foams at 70-180 deg.C, and solidifies at high temperature of 200-450 deg.C to obtain the polyimide foam which has closed cell structure and density 0.01-0.5g / cu cm.

Owner:ZHEJIANG UNIV

A kind of aromatic polyamide slurry, porous diaphragm and preparation method thereof

ActiveCN109950456BReduce moisture contentImprove securityCell component detailsPolyamidePhysical chemistry

The invention provides an aromatic polyamide slurry, which comprises the following raw materials: 15-30wt% aromatic polyamide compound, 2-15wt% reactive additives and 59-82wt% solvent, and 0.5-7wt% co-solvent can be added to the aromatic polyamide slurry, and a porous diaphragm prepared by using the aromatic polyamide slurry and a preparation method thereof are also provided. The aromatic polyamide porous diaphragm prepared by the present invention has high temperature resistance, good pore size uniformity and low moisture content, and can effectively improve the safety performance of the battery cell when applied to a lithium-ion battery while suppressing the cell capacity and degradation of cycle characteristics.

Owner:微宏先进膜公司

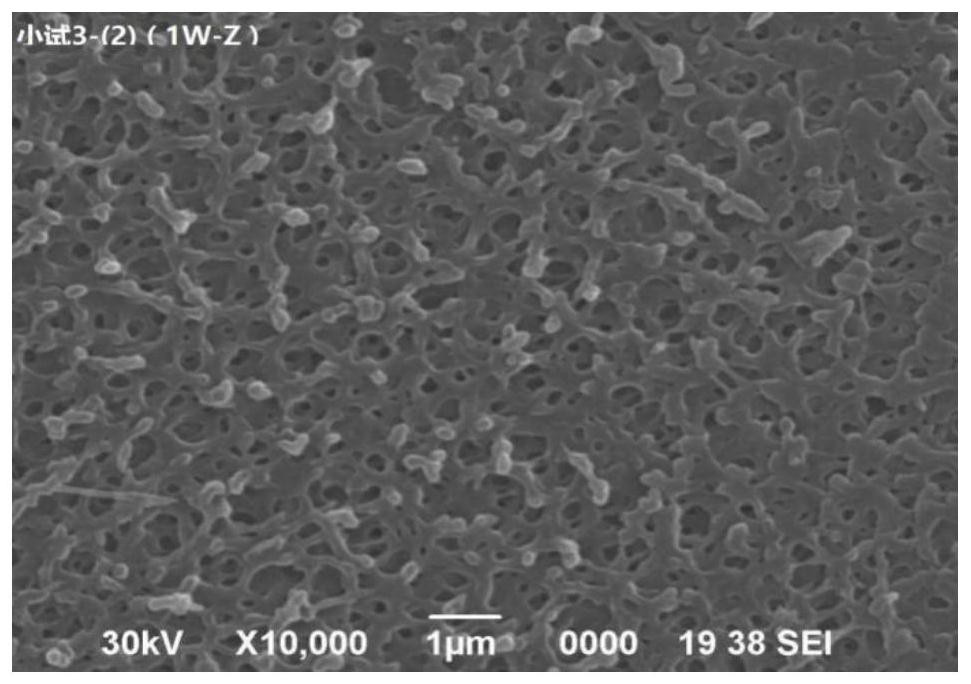

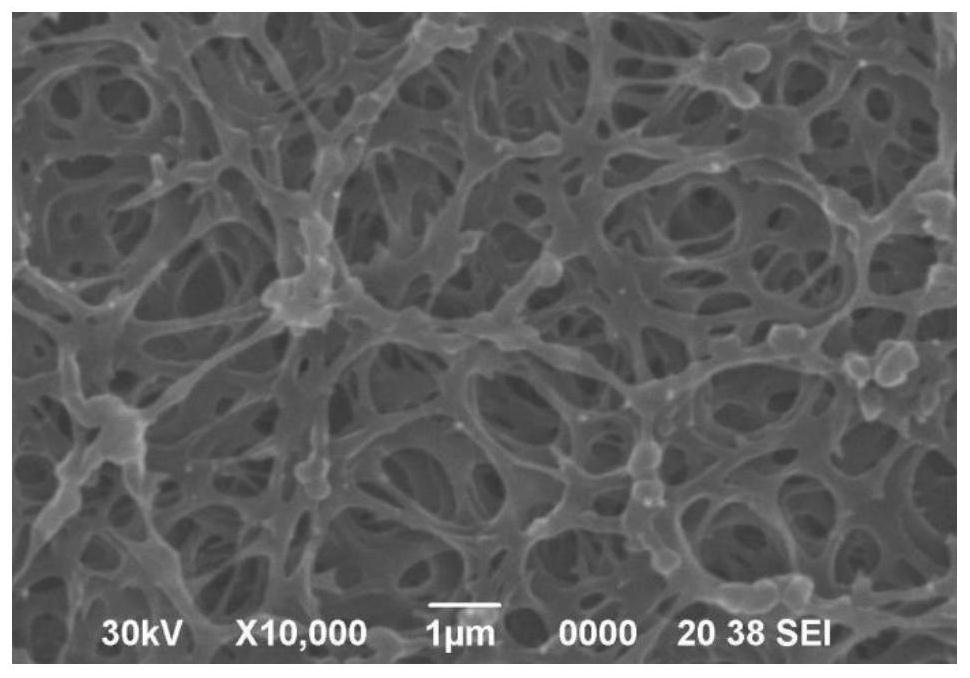

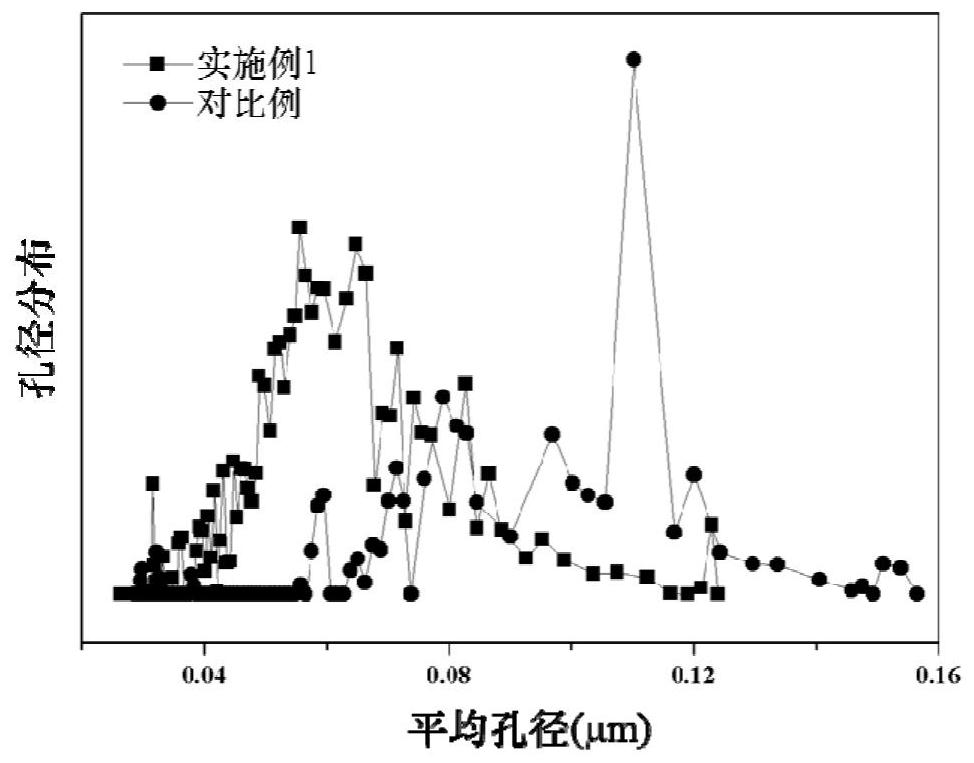

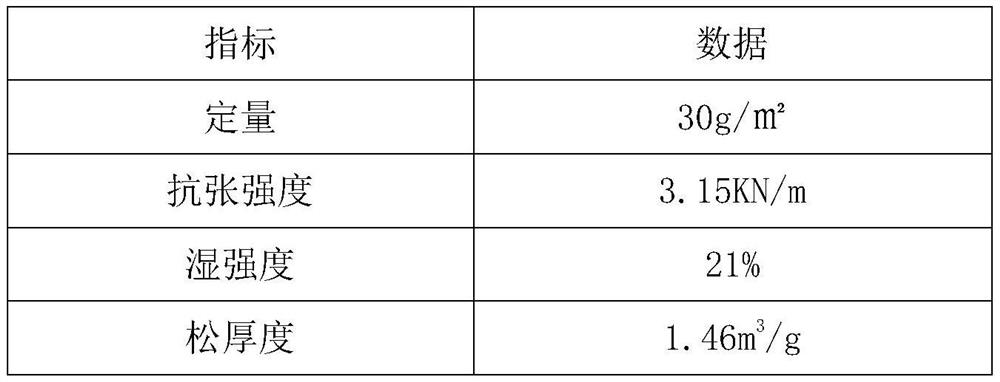

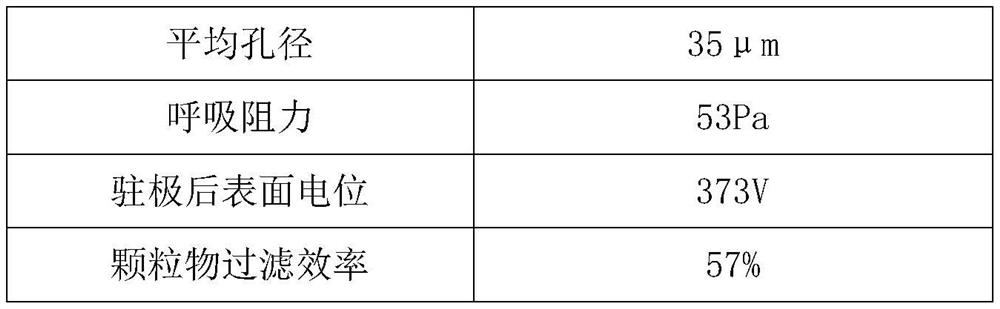

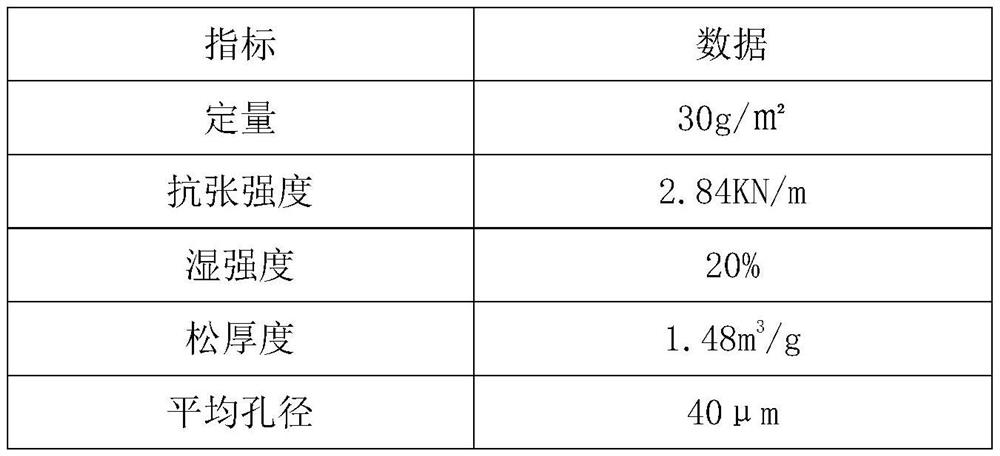

Paper-based filter material base paper for replacing mask melt-blown cloth and preparation method of paper-based filter material base paper

ActiveCN111691232ASolve the problem of large gap and low filtration efficiencyStable chargingNatural cellulose pulp/paperOrganic non-cellulose fibresPolymer sciencePlant fibre

The invention relates to paper-based filter material base paper for replacing mask melt-blown cloth and a preparation method of the paper-based filter material base paper. The paper-based filter material base paper for replacing the mask melt-blown cloth is characterized in that the physical properties are as follows: the quantification is 20-40 g / m<2>, and the tensile strength is 2 KN / m-4 KN / m; the wet strength is 15%-30%; the bulk is 1.3 to 1.8 m<3> / g; the average pore diameter is 30 [mu]m to 55 [mu]m; the respiratory resistance ranges from 30 Pa to 170 Pa; the surface potential after electret is 300 V-600 V, and the particulate matter filtering efficiency is 50%-80%. Plant fibers and polylactic acid fibers are used as filter materials for replacing polypropylene melt-blown cloth for thefirst time, and an anion fiber coating containing the nanofibers is sprayed to solve the problems that after plant fibers and polylactic acid fibers form paper, gaps are large, and the filter efficiency is low.

Owner:QILU UNIV OF TECH +1

A kind of manufacturing method of foamed aluminum alloy

Owner:有研金属复材技术有限公司

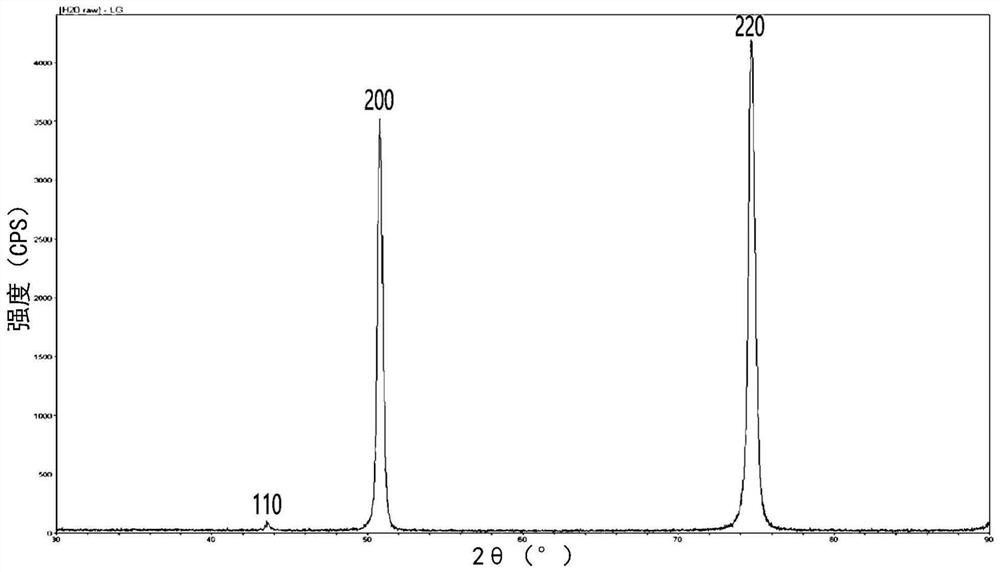

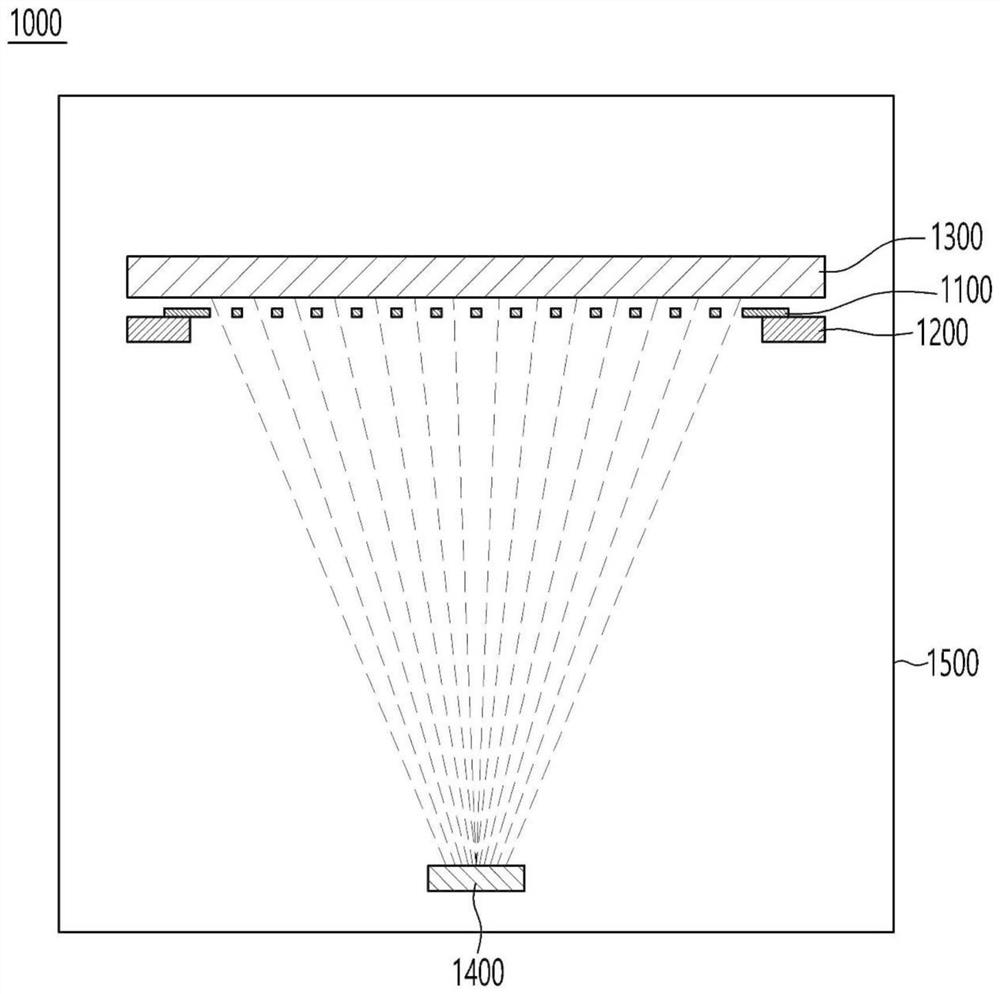

Deposition mask for OLED pixel deposition

PendingCN114657507AReduce aperture deviationGood pore size uniformitySolid-state devicesVacuum evaporation coatingCrystal planeMaterials science

Owner:LG INNOTEK CO LTD

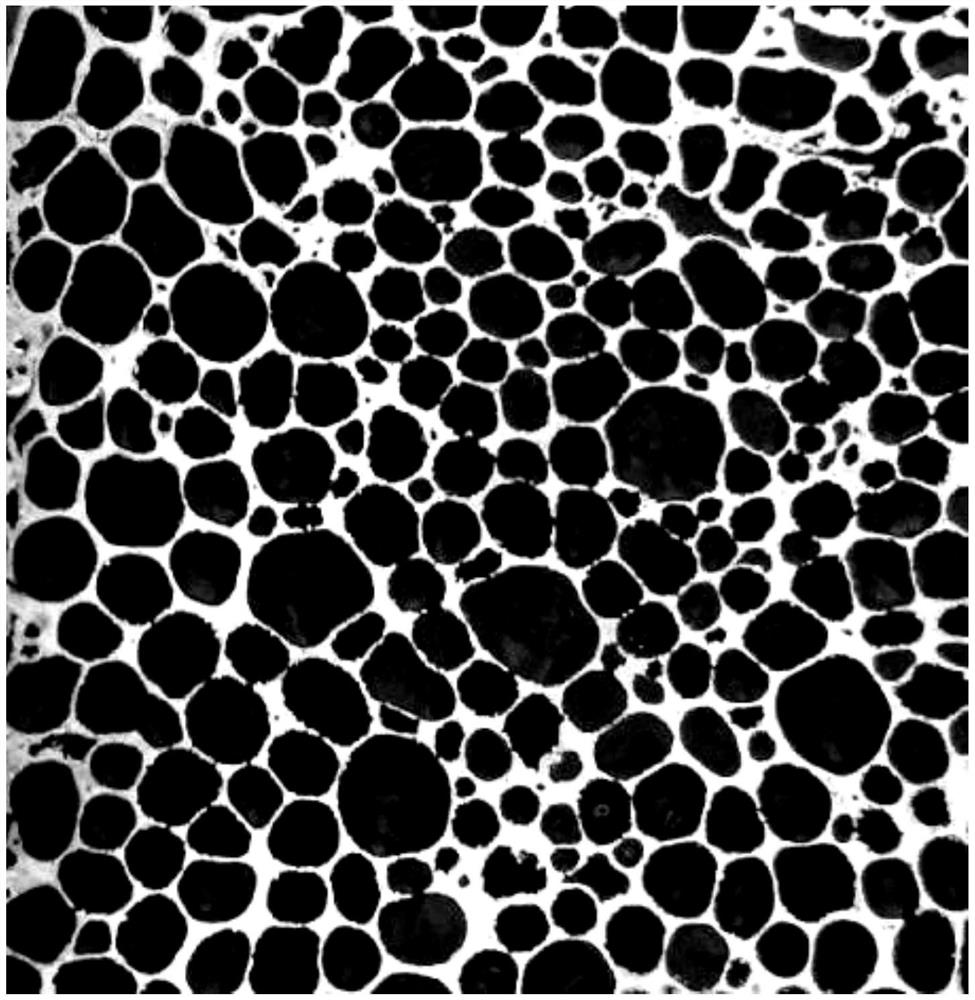

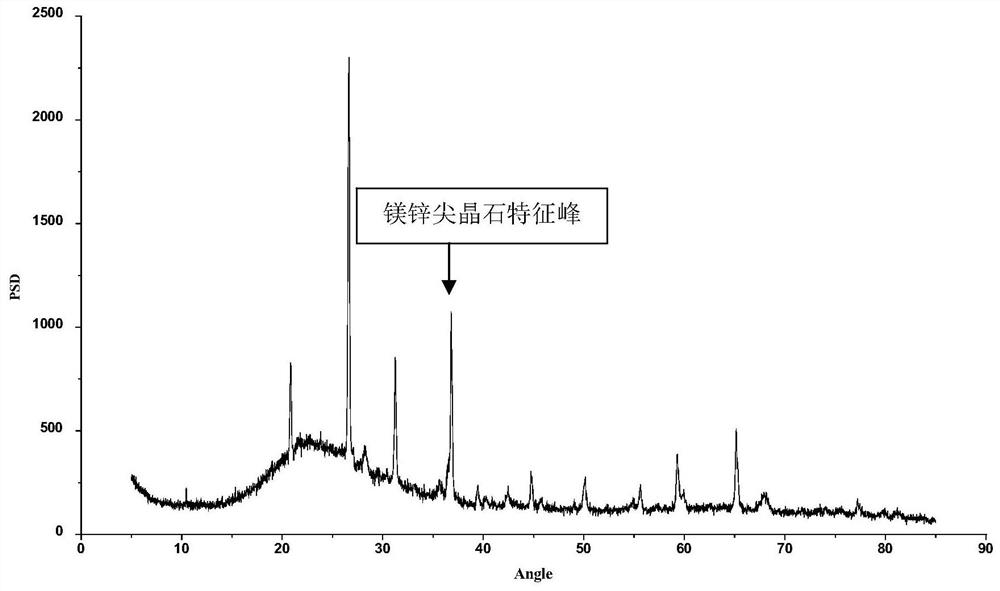

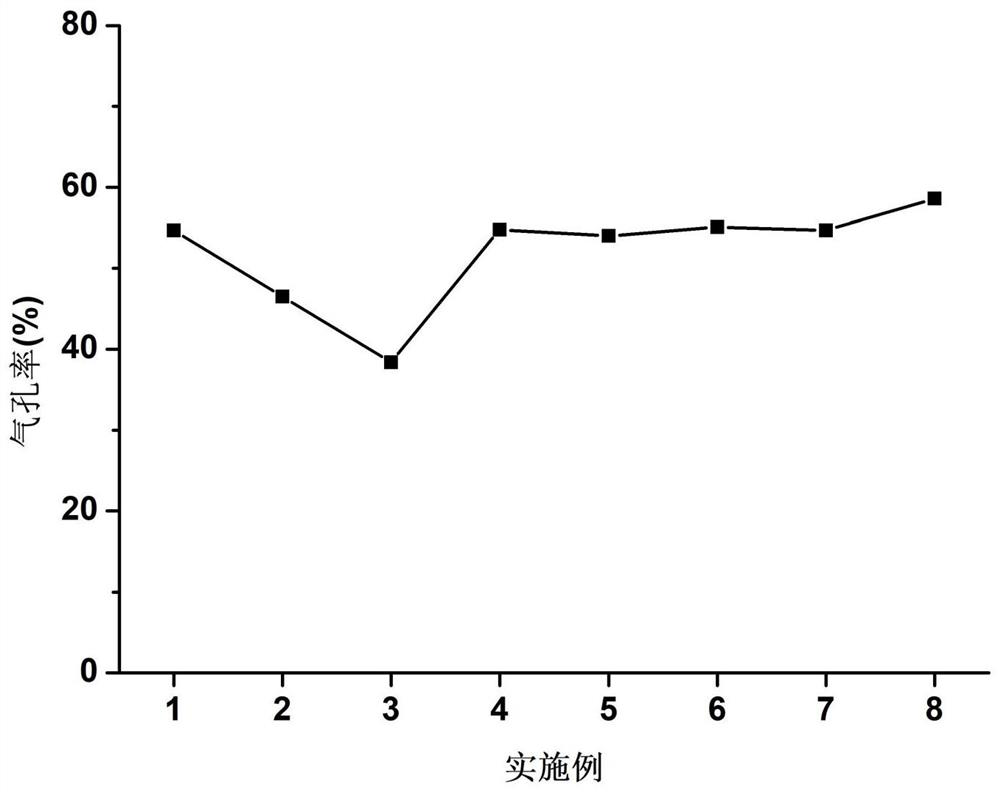

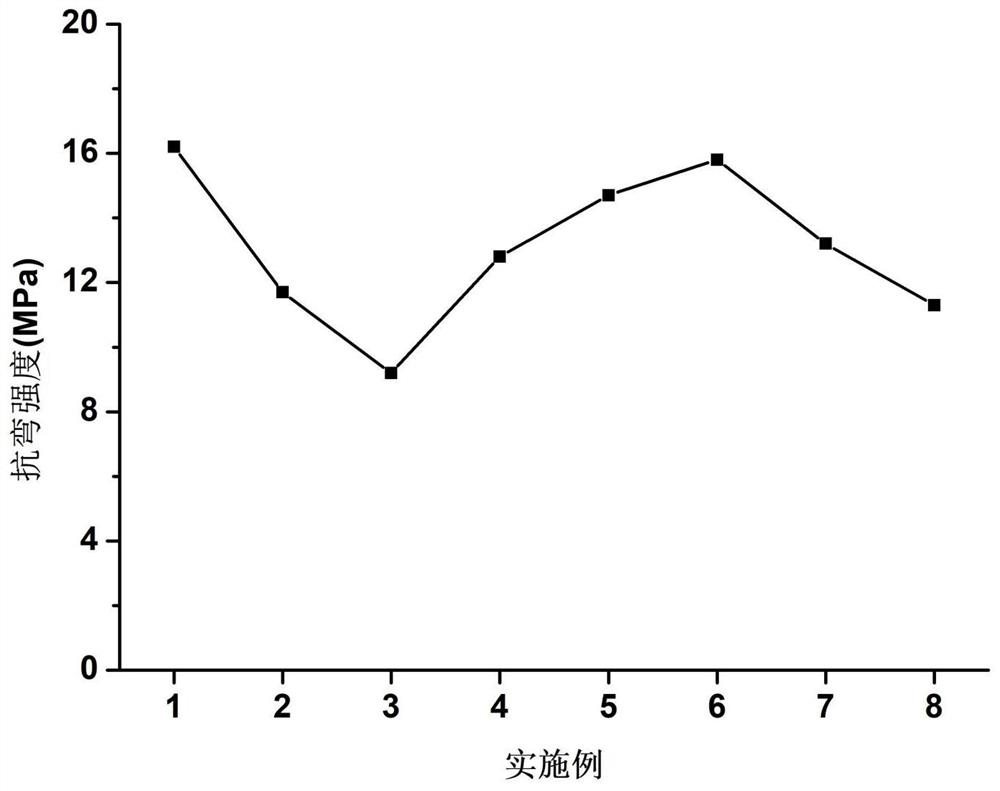

A high-strength and low-thermal-conduction foamed ceramic, a composite plate using the foamed ceramic, and a preparation method thereof

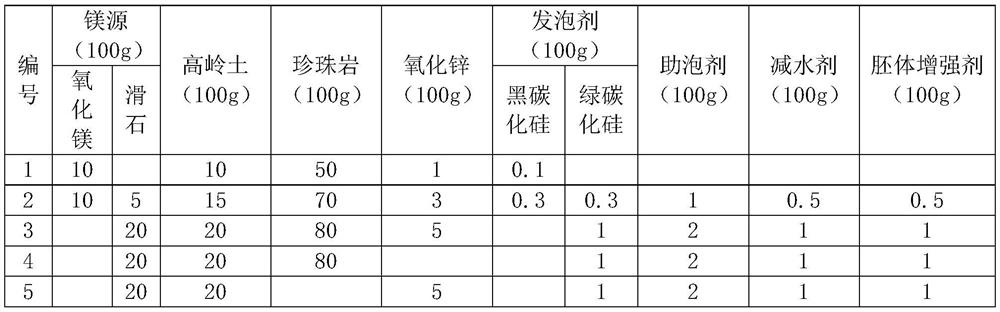

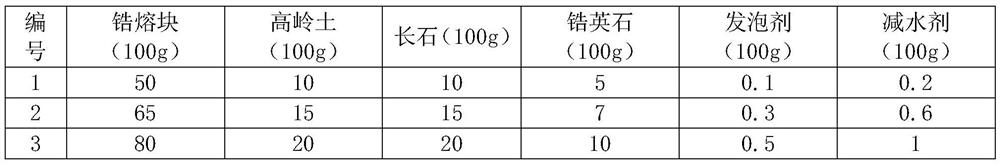

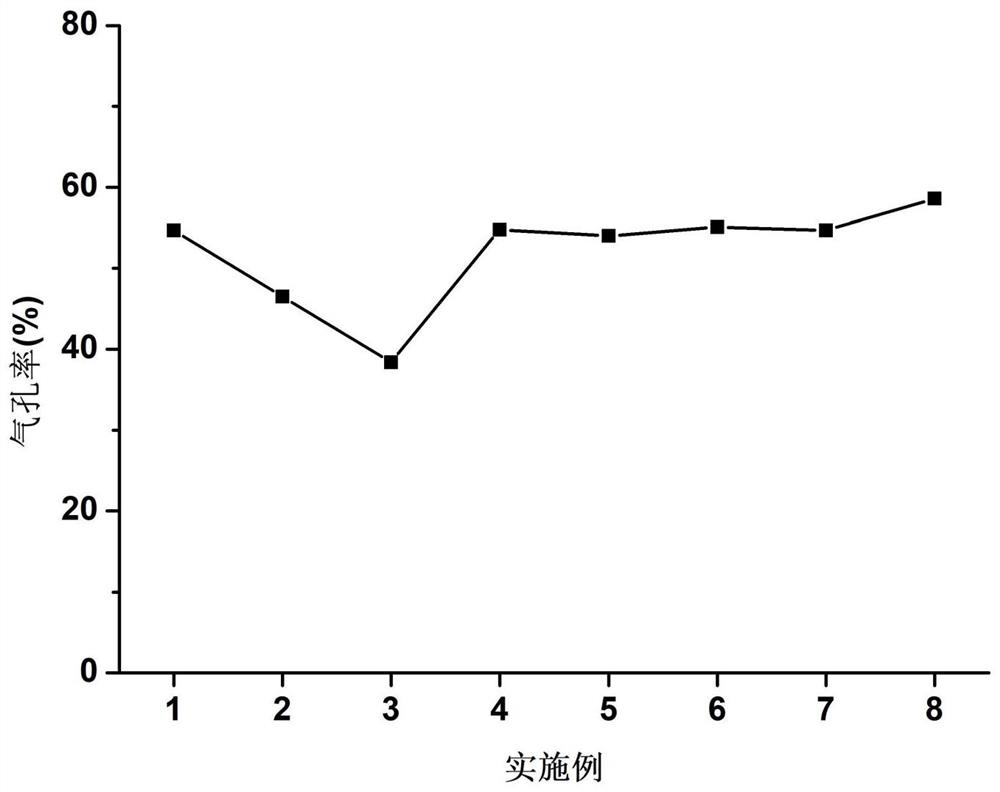

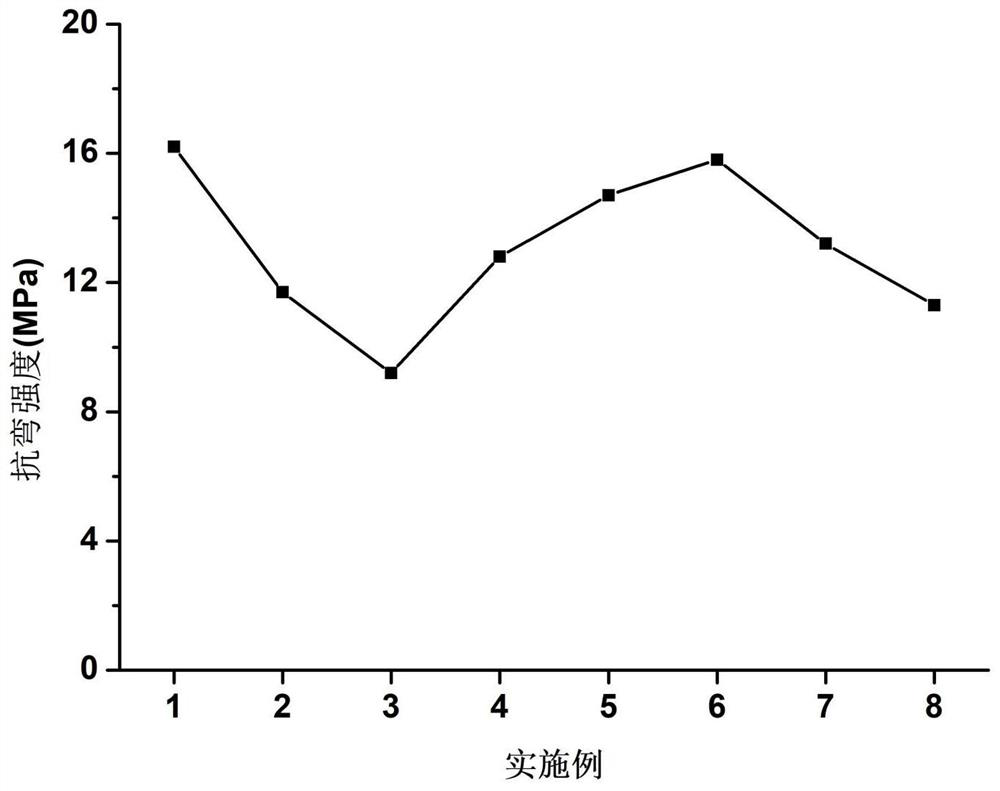

ActiveCN111153710BSmall sizeGood pore size uniformityCeramic shaping apparatusCeramicwareFoaming agentPtru catalyst

A high-strength and low-thermal-conduction foamed ceramic, a composite board using the foamed ceramic, and a preparation method thereof. The synthetic raw materials of the foamed ceramic include the following materials: magnesium source, aluminum source, silicon source, zinc source, foaming agent, The foamed ceramic contains magnesium-zinc spinel generated in situ. In this application, the zinc source is used as a catalyst. During the heating process, enstatite and magnesium-zinc spinel solid solutions are first formed. As the temperature increases, enstatite gradually dissolves, and the amount of magnesium-zinc spinel solid solutions gradually increases; During the high-temperature foaming process, the in-situ synthesized magnesium-zinc spinel solid solution crystallites have a pinning effect in the melt, which can reduce the rate of melt viscosity drop, effectively control the abnormal increase of pores, and obtain good uniformity of the pores. , Small-sized foamed ceramics.

Owner:山东晟世达科技有限公司

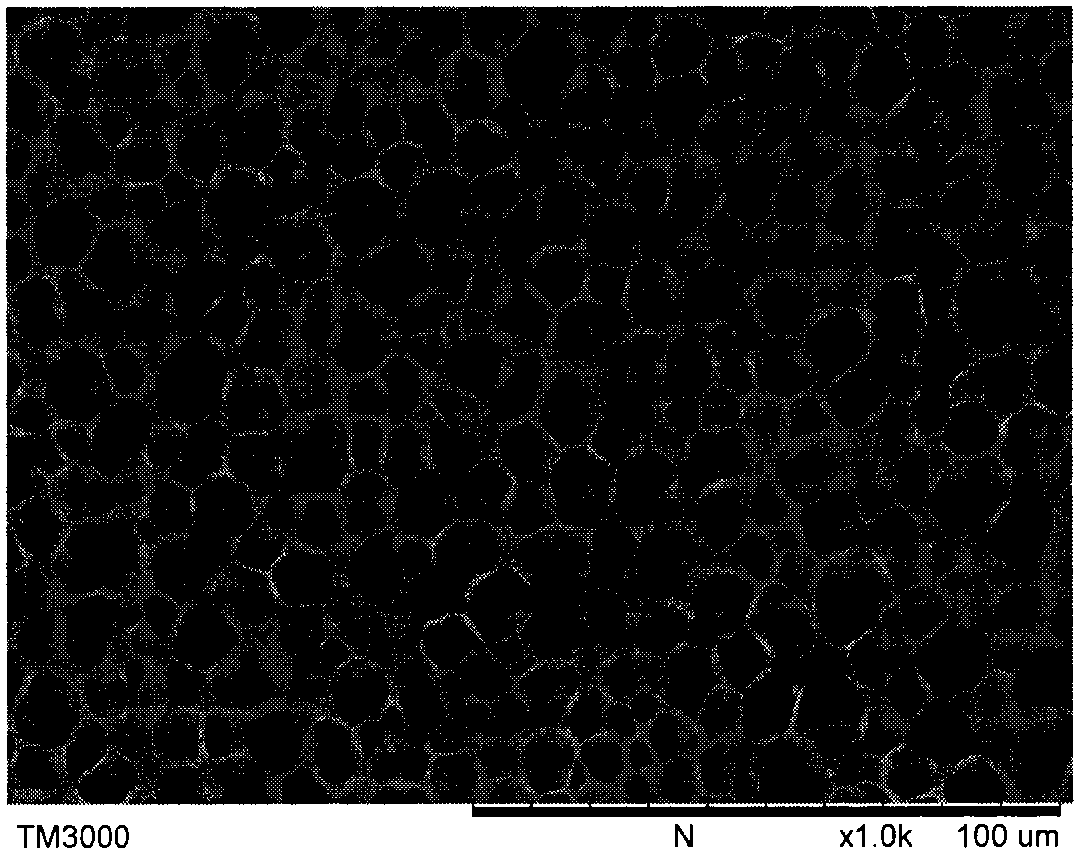

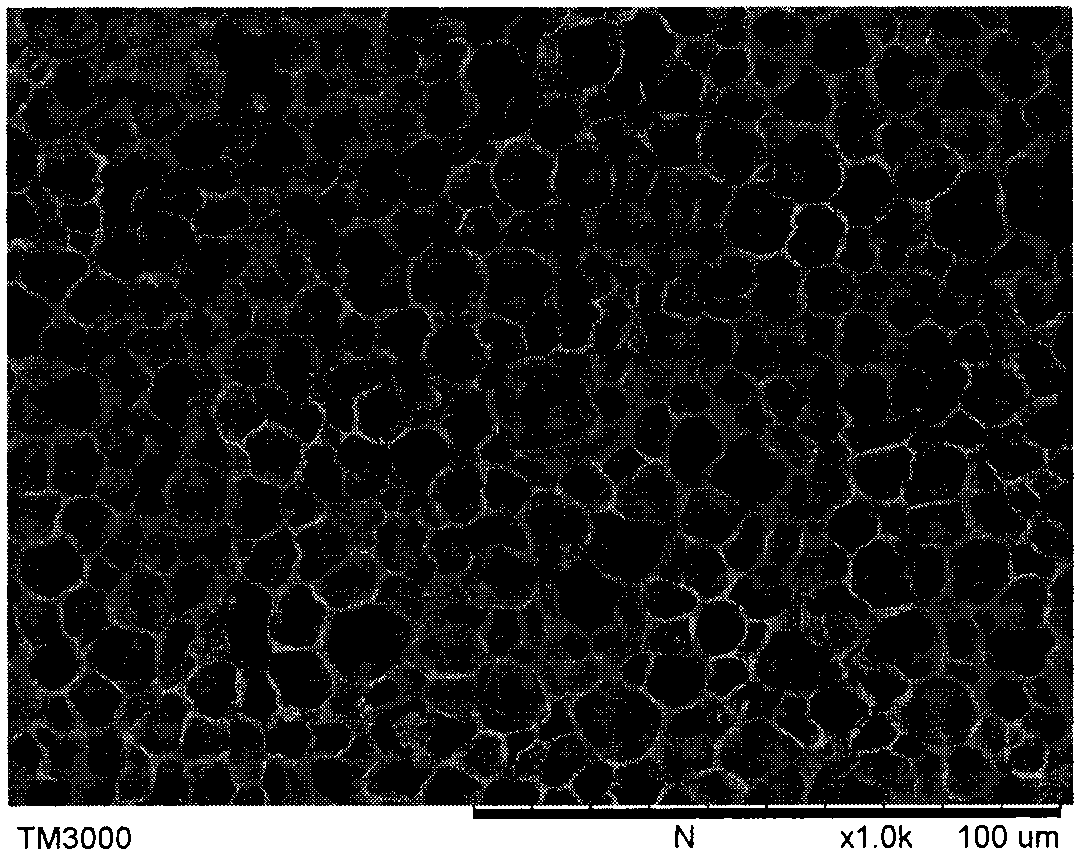

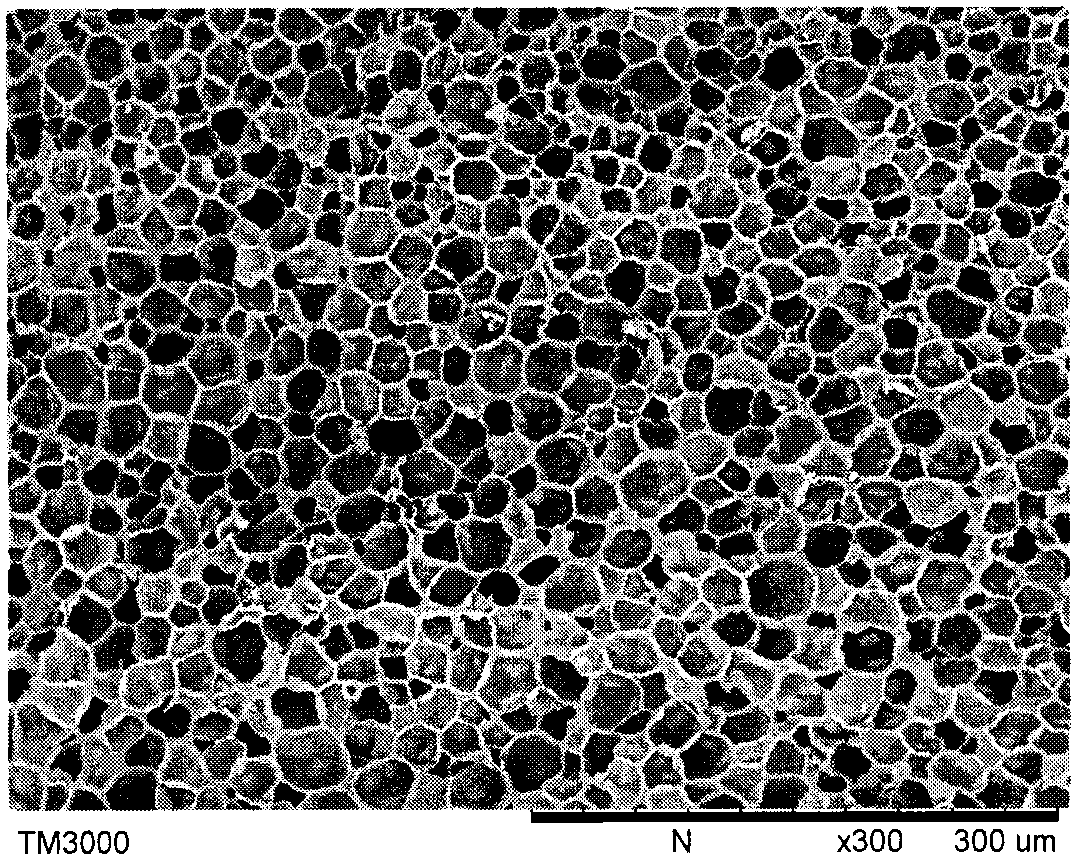

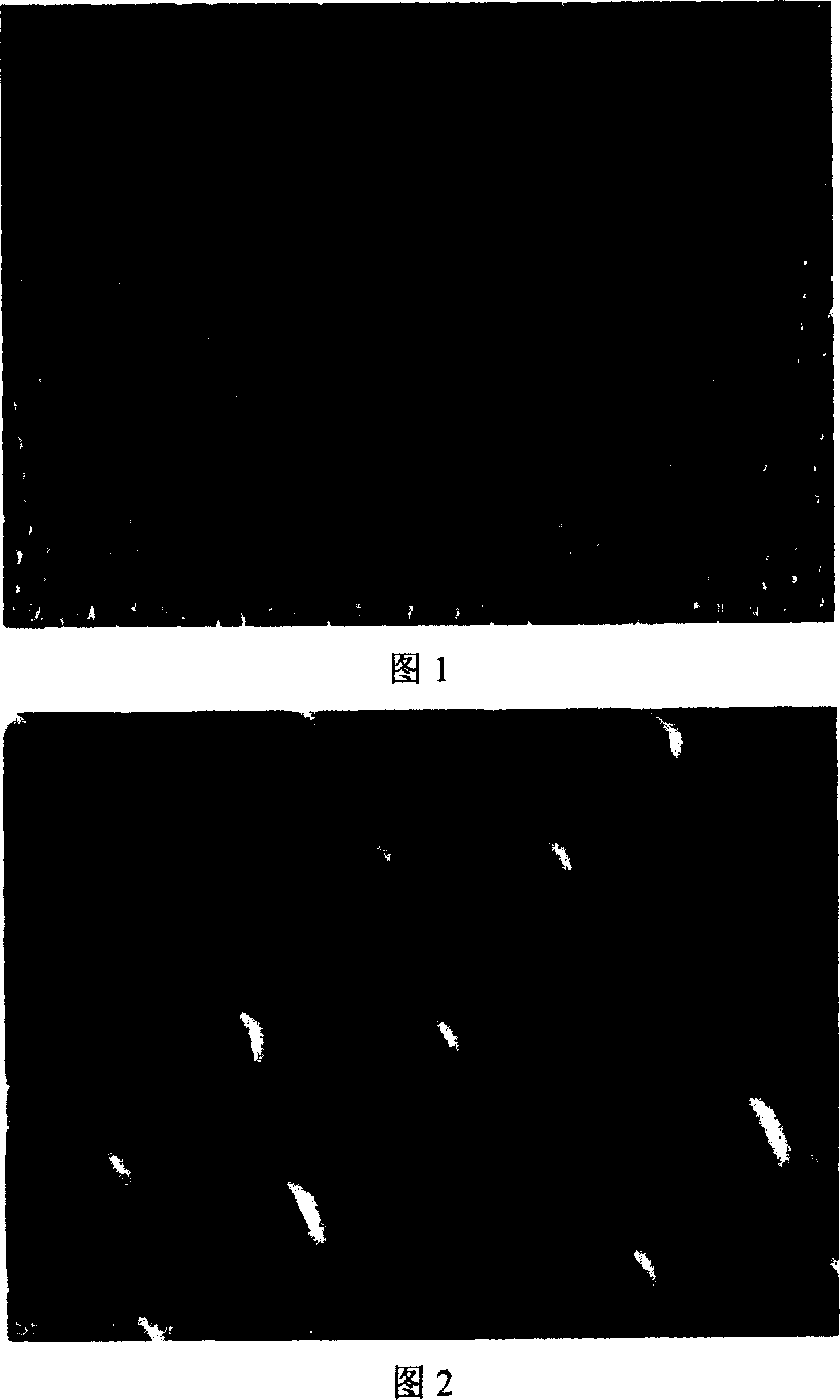

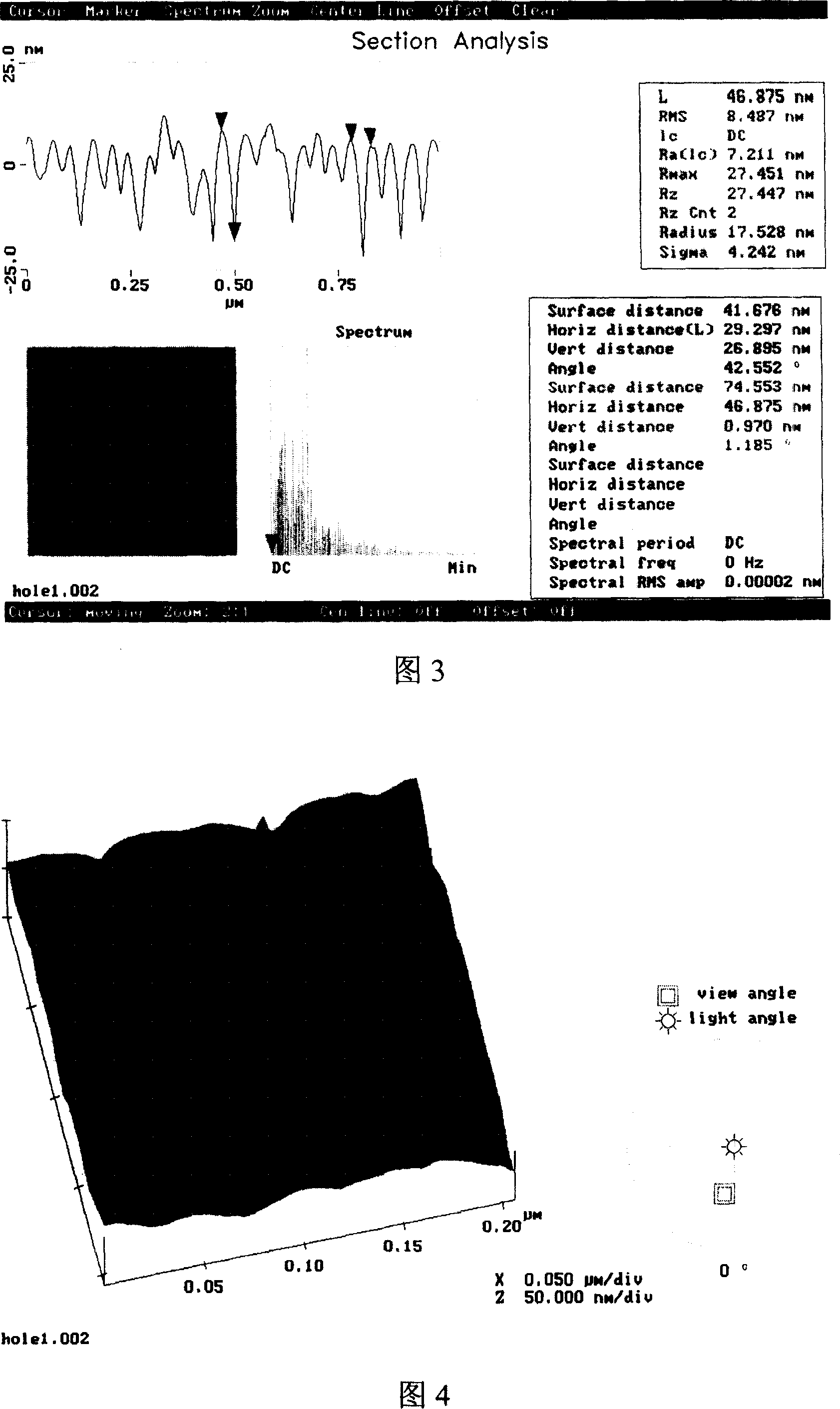

Process for producing ordered porous anodic alumina form

The present invention discloses one kind of ordered porous anode oxidized alumina template preparing process. Compared with available technology, the said process has the advantages of capacity one preparing great area highly ordered nanometer template, high template success rate and high template quality including raised nanometer pore arrangement orderliness, pore size homogeneity, depth uniformity and porosity.

Owner:DONGGUAN UNIV OF TECH

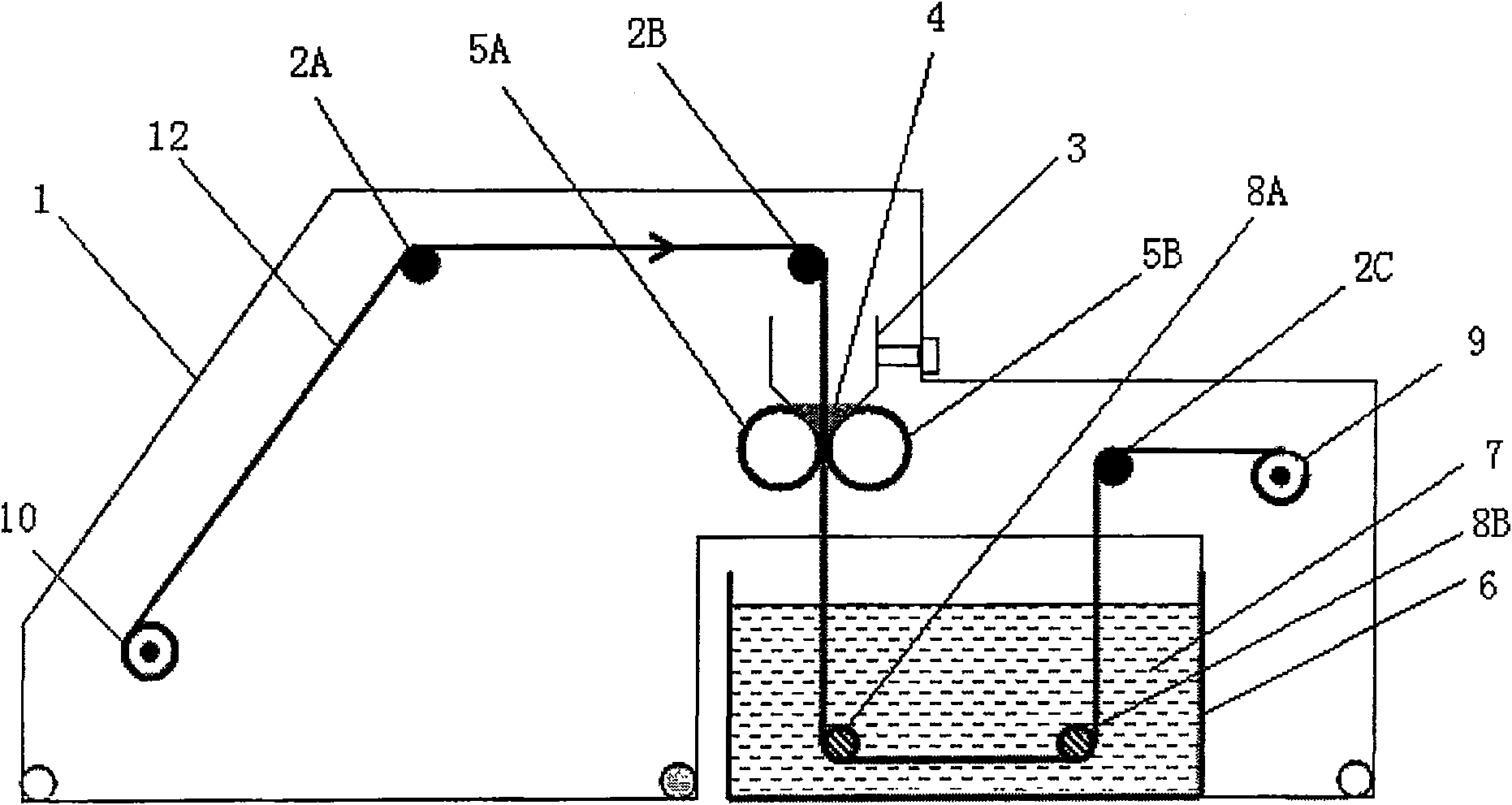

A plate-shaped corrugated membrane diaphragm with uniform pore size and its preparation method

ActiveCN106512748BAvoid fitImprove hydrophilic abilitySemi-permeable membranesSewageSewage treatment

The invention relates to a plate-shaped corrugated membrane diaphragm having uniform aperture and a preparation method thereof, which belong to the technical field of sewage processing. According to the invention, a plate-shaped membrane having a corrugated shape is employed, and the method comprises a high-energy radiation etching step, a PET extrusion moulding step and a marking radiation pore-forming step; the PET extrusion moulding step employs a PET extrusion form to form a heterotype diaphragm, a nuclear track membrane moulding technology step is used on the heterotype diaphragm for completing the moulding of the aperture; and the plate-shaped corrugated membrane diaphragm having uniform aperture is prepared. The plate-shaped corrugated membrane diaphragm having uniform aperture has the advantages that PET extrusion moulding and the marking radiation pore-forming technology are combined, the corrugated plate-shaped membrane is obtained through PET extrusion, diaphragm applying while operation can be effectively prevented, the hydrophilic performance of a PET material is stronger than that of PVDF, good aperture uniformity can be guaranteed by the radiation pore-forming technology, and better effect of the plate-shaped corrugated membrane can be obtained through a plurality of effects.

Owner:BEIJING ORIGIN WATER FILM TECH

Ceramic flat sheet membrane for perishable garbage sewage treatment and preparation method thereof

ActiveCN113198333AHigh porositySmall filter resistanceMembranesSemi-permeable membranesStyrene oxideOxide ceramic

The invention belongs to the technical field of inorganic membrane materials, and particularly relates to a ceramic flat sheet membrane for perishable garbage sewage treatment and a preparation method thereof. The invention provides the ceramic flat sheet membrane for perishable garbage sewage treatment. The ceramic flat sheet membrane comprises an aluminum oxide ceramic flat sheet membrane support body, a separation membrane layer and a polymer membrane layer, wherein the outer surface of the ceramic flat sheet membrane support body is coated with the separation membrane layer; the support body comprises aluminum oxide powder, a binding agent, a dispersing agent and a pore forming agent; the separation membrane layer comprises aluminum oxide powder, styrene oxide modified calcite powder, a binding agent, a dispersing agent and a pore forming agent; and the polymer film layer is perfluoropolyether carboxylic acid cross-linked dehydroabietylamine. The ceramic flat sheet membrane is good in surface hydrophilicity, high in water flux, high in mechanical strength, good in filtering performance, excellent in anti-pollution performance and long in service life.

Owner:HANGZHOU NAXI ECOLOGICAL TECH CO LTD

Ceramic flat membrane for perishable waste sewage treatment and preparation method thereof

ActiveCN113198333BHigh porositySmall filter resistanceMembranesSemi-permeable membranesEthylene oxideCarboxylic acid

The invention belongs to the technical field of inorganic membrane materials, and in particular relates to a ceramic flat membrane for perishable waste sewage treatment and a preparation method thereof. The invention provides a ceramic flat membrane for perishable waste sewage treatment, comprising an alumina ceramic flat membrane support body, a separation membrane layer and a polymer membrane layer coated on the outer surface of the ceramic flat membrane support body; Aluminum powder, binder, dispersant, and pore-forming agent; the separation membrane layer includes alumina powder, styrene oxide modified calcite powder, binder, dispersant, and pore-forming agent; the polymer membrane layer is perfluorinated Polyether carboxylic acid cross-linked dehydroabietic amine; the surface of ceramic flat membrane has good hydrophilicity, high water flux, high mechanical strength, good filtration performance, excellent anti-pollution performance and long service life.

Owner:HANGZHOU NAXI ECOLOGICAL TECH CO LTD

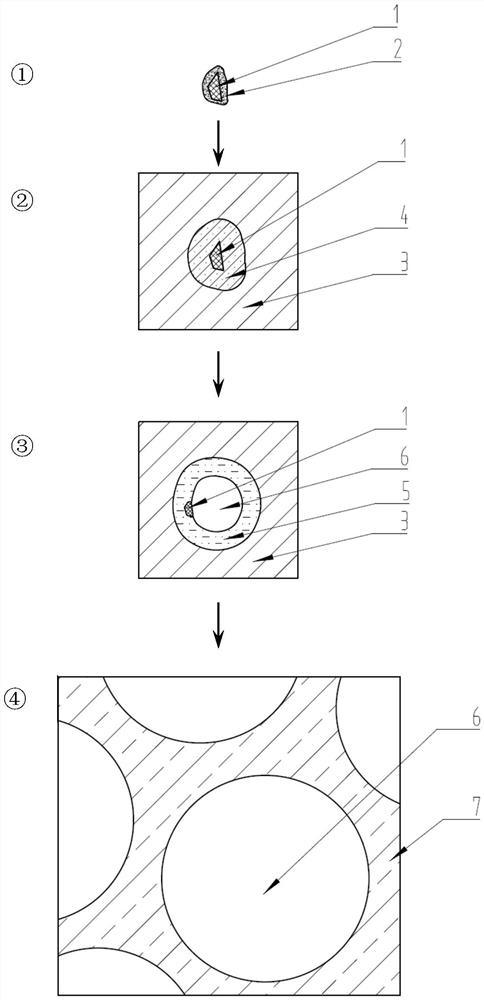

A method for preparing a stent with interconnected apertures

A making method of an aperture connected support comprises the following steps: spraying expansion material powder particles to the aperture connected support, and expanding. The controllable adjustment of the size of the apertures of the support is realized through the making method, and the aperture connected support made in the invention has good uniformity. Porous metal materials prepared by adopting the above porous support made in the invention have the advantages of uniform distribution, arbitrary adjustment of the porosity, and wide uses.

Owner:CHONGQING RUNZE PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com