Ceramic flat membrane for perishable waste sewage treatment and preparation method thereof

A technology for sewage treatment and flat membrane, applied in the field of membrane materials, can solve the problems of low water flux, poor hydrophilicity, low anti-pollution performance, etc., and achieve good pore size uniformity, excellent mechanical strength, and steric hindrance. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

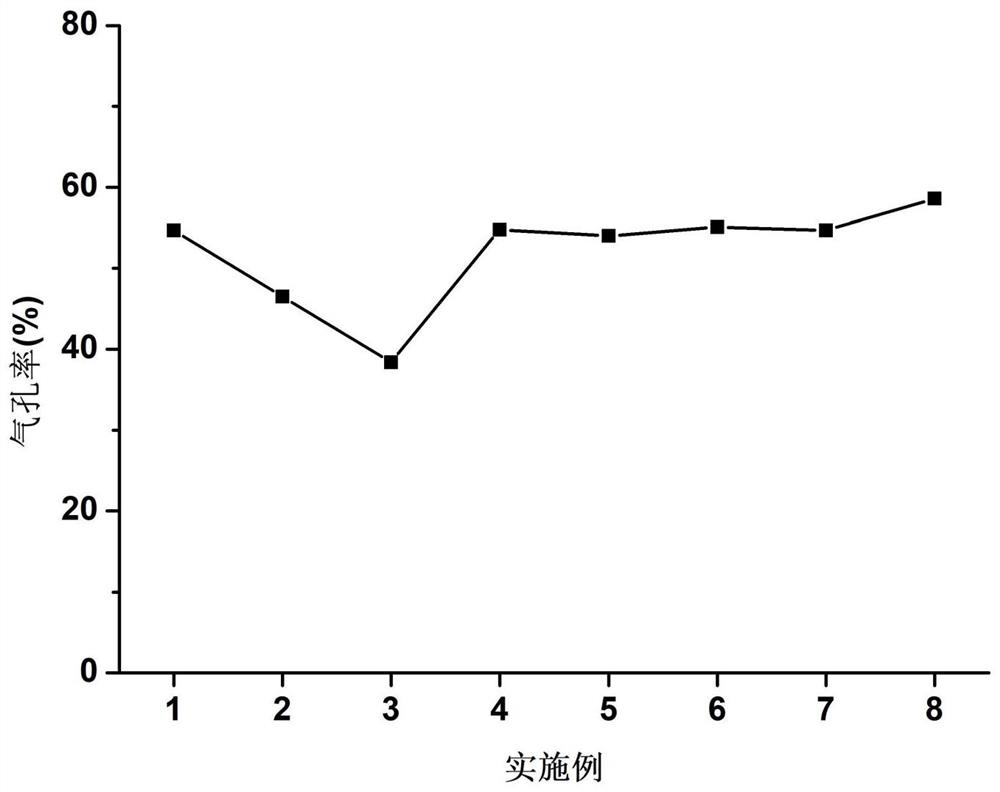

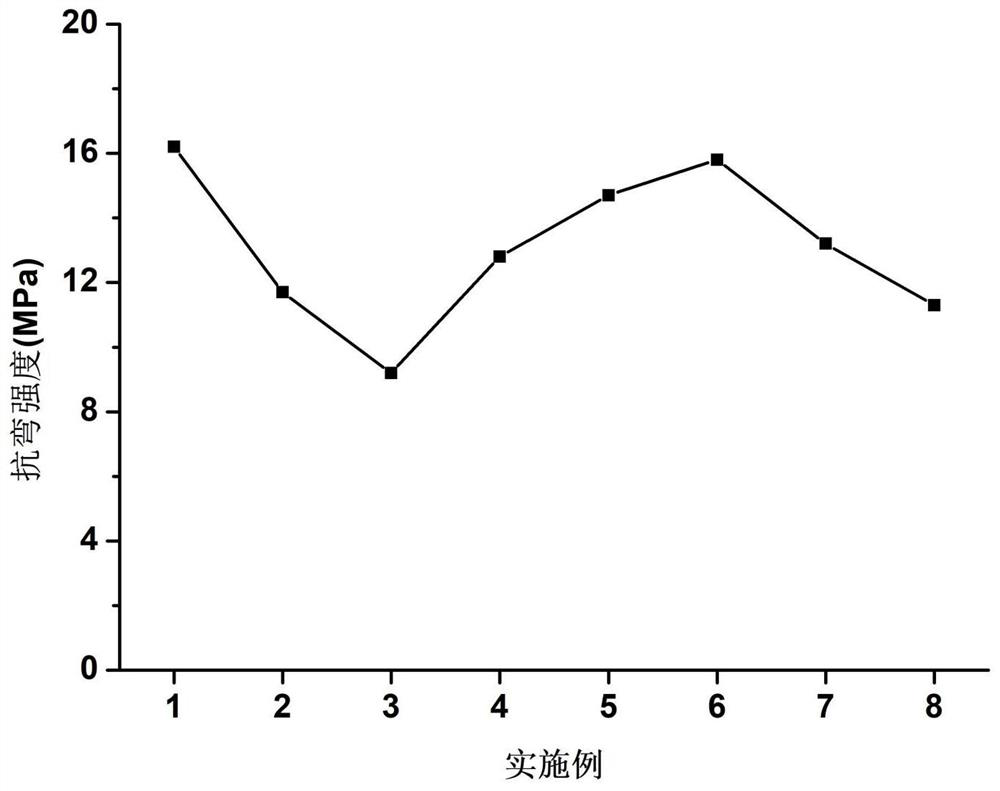

[0058] Example 1: A ceramic flat membrane for perishable waste sewage treatment:

[0059] The present embodiment provides a ceramic flat membrane for perishable waste sewage treatment, which is prepared by the following method:

[0060] 1) Preparation of support body:

[0061] Disperse 10g of sodium polyacrylate into 200g of water, add 750g of alumina, ball mill at 150r / min for 30min to obtain a mixture, then add 40g of silica sol, 120g of aluminum dihydrogen phosphate sol, and 80g of starch, ultrasonically treat for 30min, and the ultrasonic frequency is 20kW , the power density is 0.3W / cm 2 , put the mixture in an airtight container for 24 hours, cold isostatic pressing at 100MPa, vacuum drying at 60°C, heating up to 850°C at a rate of 10°C / min and holding for 20 minutes, and then heating at a rate of 5°C / min to 1150°C and kept for 10min to obtain an alumina ceramic flat membrane support;

[0062] 2) Preparation of separation membrane layer:

[0063] Mix 80g calcite powd...

Embodiment 2

[0066] Example 2: Another ceramic flat membrane for perishable waste sewage treatment:

[0067] This embodiment provides another ceramic flat membrane for perishable waste sewage treatment, the preparation method of which is basically the same as that of embodiment 1, the difference is that in this embodiment, the specific steps of the process of preparing the separation membrane layer are:

[0068] Disperse 10g of sodium polyacrylate into 450g of water, add 120g of alumina powder, 80g of calcite, 20g of silica sol, 30g of aluminum dihydrogen phosphate sol, 30g of starch, ball mill at 500r / min for 4h to obtain the separation membrane slurry, and then the support The body was immersed in the separation membrane layer slurry for 1 min, dried at room temperature, and then heated to 1250 °C for 30 min at a rate of 8 °C / min to obtain a ceramic flat membrane with a separation membrane layer supported on the surface; Sexual calcite.

Embodiment 3

[0069] Example 3: Another ceramic flat membrane for perishable waste sewage treatment:

[0070] This embodiment provides another ceramic flat membrane for perishable waste sewage treatment, the preparation method of which is basically the same as that of embodiment 1, the difference is that in this embodiment, the specific steps of the process of preparing the separation membrane layer are:

[0071] Disperse 10g of sodium polyacrylate into 450g of water, add 120g of alumina powder, 20g of silica sol, 30g of aluminum dihydrogen phosphate sol, 30g of starch, ball mill at 500r / min for 4h to obtain the separation membrane layer slurry, and then immerse the support in The separation membrane layer was placed in the slurry for 1 min, dried at room temperature, and then heated to 1250 °C for 30 min at a rate of 8 °C / min to obtain a ceramic flat membrane with a separation membrane layer supported on the surface; that is, no ethylene oxide modified calcite was added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com