Elastic material and application thereof

An elastic material and weight percentage technology, applied in the field of elastic materials, can solve the problems of insufficient elasticity, tear resistance and peel resistance of EVA cross-linked foam materials, and achieve improved pore size uniformity, hardness and tensile strength. Reduced, small aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

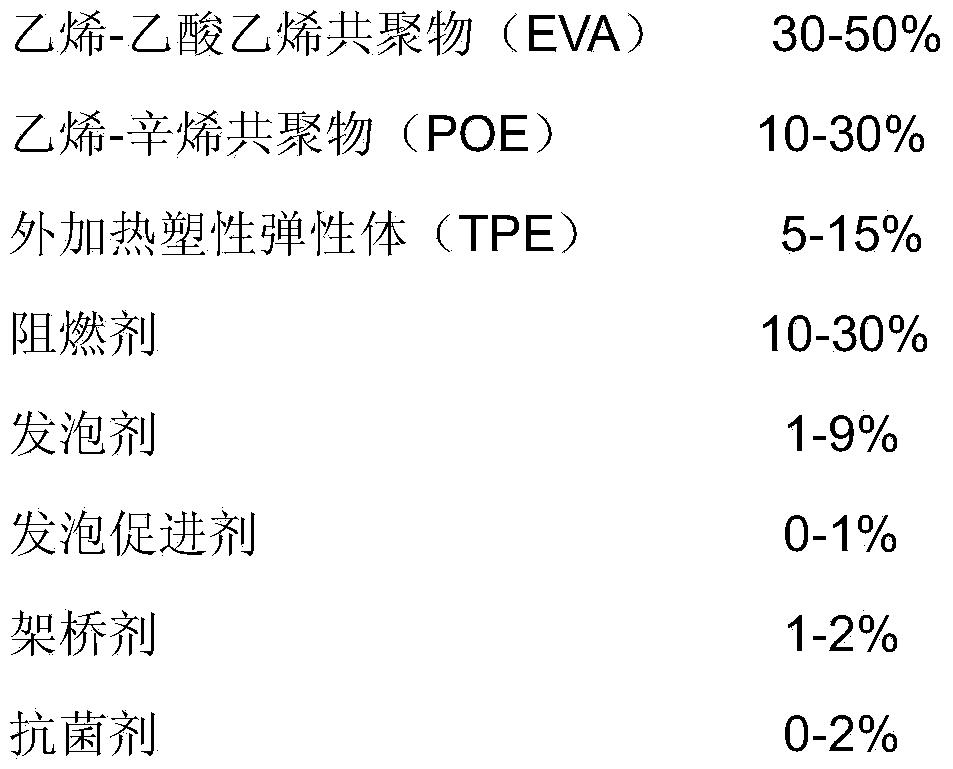

[0028] An elastic material is foamed after mixing the following components and the weight percentages of each component:

[0029]

[0030] The above components are kneaded at a mixing temperature of about 100°C, then molded and foamed in a vulcanizer at a foaming temperature of about 180°C, finally cooled and shaped, and then sampled.

Embodiment 2

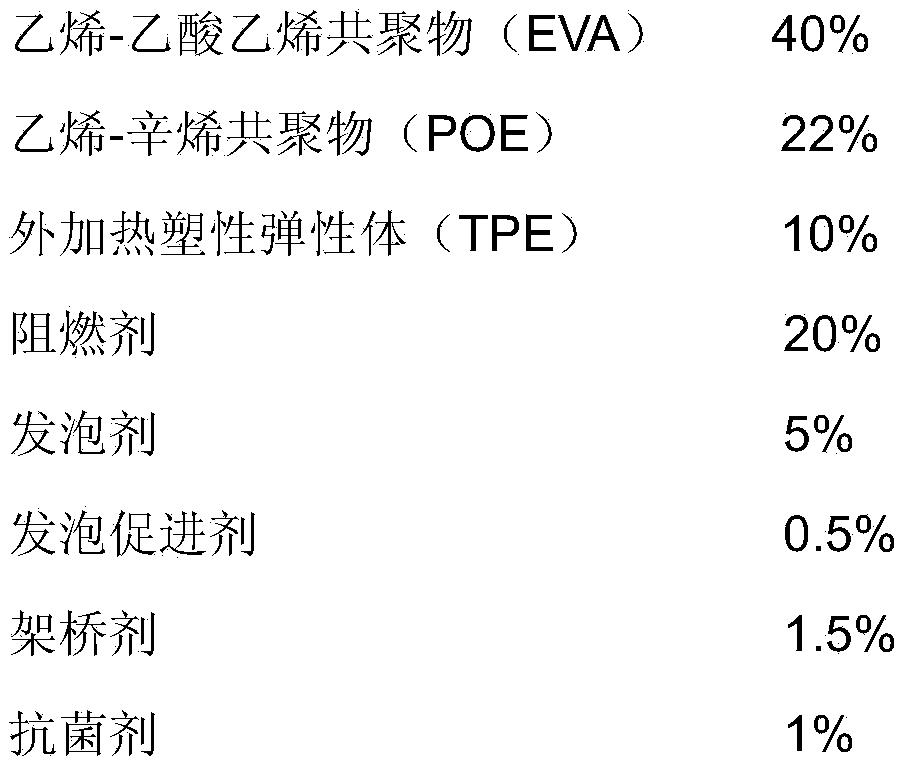

[0032] An elastic material is foamed after mixing the following components and the weight percentages of each component:

[0033]

[0034] The above components are kneaded at a mixing temperature of about 100°C, then molded and foamed in a vulcanizer at a foaming temperature of about 180°C, finally cooled and shaped, and then sampled.

Embodiment 3

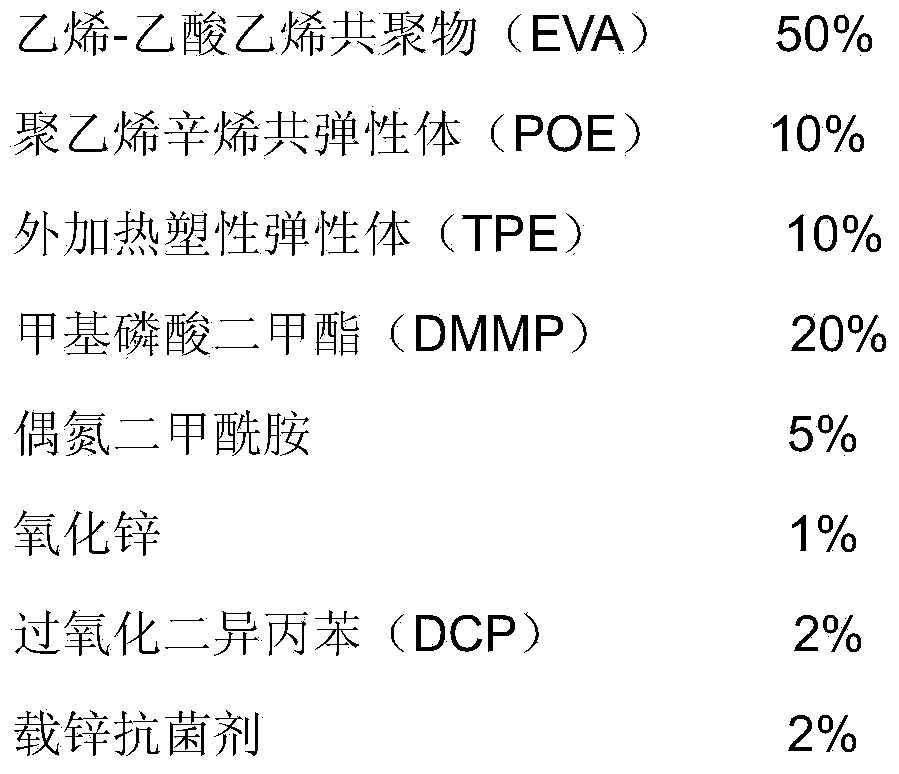

[0036] An elastic material is foamed after mixing the following components and the weight percentages of each component:

[0037]

[0038] The above components are kneaded at a mixing temperature of about 100°C, then molded and foamed in a vulcanizer at a foaming temperature of about 180°C, finally cooled and shaped, and then sampled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com