Paper-based filter material base paper for replacing mask melt-blown cloth and preparation method of paper-based filter material base paper

A filter material and paper-based technology, applied in paper coating, filtration separation, membrane filter, etc., can solve the problem of large pore size of plant fiber and polylactic acid fiber, fast decay of electret charge of polylactic acid fiber, polypropylene melt blown To solve the problems of low cloth output, etc., to achieve the effect of abundant raw materials, uniform filtration efficiency, and improved electrostatic adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

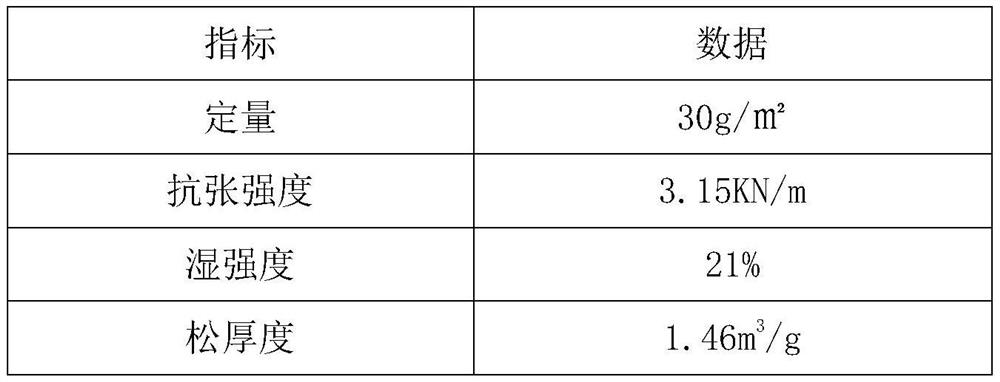

Embodiment 1

[0072] A kind of paper-based filter material raw paper that replaces mask melt-blown cloth and preparation method thereof, the steps are as follows:

[0073] (1) Mix the polylactic acid fiber accounting for 30% of the total fiber mass ratio with the softwood fiber with a beating degree of 30°SR accounting for 70% of the total fiber mass ratio, and add 0.5% of the total fiber mass as a papermaking wet strength agent polyamide Ammonia epichlorohydrin, and disperse evenly, make slurry;

[0074] (2) After diluting the slurry prepared in step (1) to a concentration of 0.025%, the paper machine is loaded, and the paper is formed by inclined wire forming to obtain a wet paper web;

[0075] (3) to the wet paper web surface that step (2) makes the negative ion fiber coating that above-mentioned making is sprayed, sprays upper surface, and spray amount is 3.5g / m in terms of solids 2 , and then according to the drying process of 30g / ㎡ sanitary napkin base paper and the subsequent paper-...

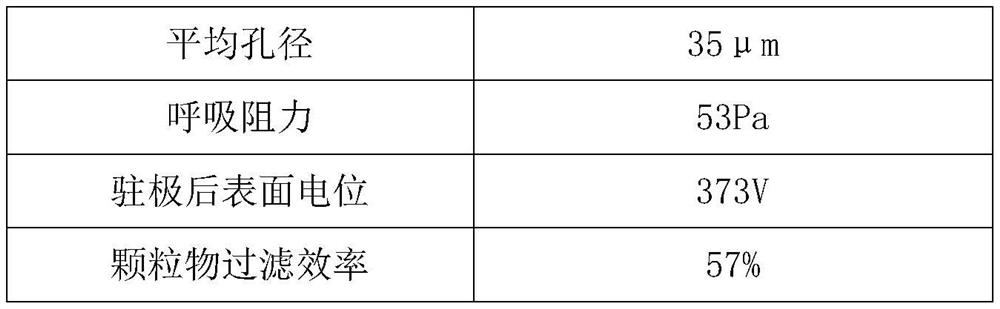

Embodiment 2

[0080] A kind of paper-based filter material raw paper that replaces mask melt-blown cloth and preparation method thereof, the steps are as follows:

[0081] (1) The polylactic acid fiber accounting for 40% of the total fiber mass ratio and the coniferous wood fiber with a beating degree of 30°SR accounting for 60% of the total fiber mass ratio are mixed, and 0.5% of the total fiber mass is added. Ammonia epichlorohydrin, and disperse evenly, make slurry;

[0082] (2) After diluting the slurry prepared in step (1) to a concentration of 0.025%, the paper machine is loaded, and the paper is formed by inclined wire forming to obtain a wet paper web;

[0083] (3) spray the negative ion fiber coating that embodiment 1 makes to the wet paper web surface that step (2) makes, spray the upper surface, and the spray amount is 3.5g / m in terms of solids 2 , and then according to the drying process of 30g / ㎡ sanitary napkin base paper and the subsequent paper-making process, the paper-base...

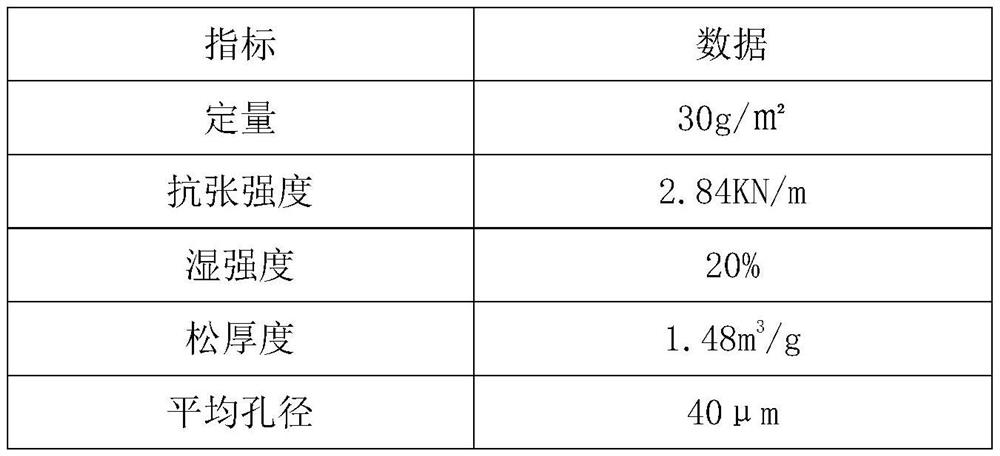

Embodiment 3

[0088]A kind of paper-based filter material raw paper that replaces mask melt-blown cloth and preparation method thereof, the steps are as follows:

[0089] (1) The polylactic acid fiber accounting for 20% of the total fiber mass ratio and the coniferous wood fiber accounting for 80% of the total fiber mass ratio with a beating degree of 30 ° SR are mixed, and 0.5% of the total fiber mass is added. Ammonia epichlorohydrin, and disperse evenly, make slurry;

[0090] (2) After diluting the slurry prepared in step (1) to a concentration of 0.025%, the paper machine is loaded, and the paper is formed by inclined wire forming to obtain a wet paper web;

[0091] (3) spray the negative ion fiber coating that embodiment 1 makes to the wet paper web surface that step (2) makes, spray the upper surface, and the spray amount is 3.5g / m in terms of solids 2 , and then according to the drying process of 30g / ㎡ sanitary napkin base paper and the subsequent paper-making process, the paper-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com