A high-strength and low-thermal-conduction foamed ceramic, a composite plate using the foamed ceramic, and a preparation method thereof

A technology of foamed ceramics and ceramic plates, applied in ceramic products, ceramic molding machines, applications, etc., can solve the problems of loss of decorative effect, poor durability of organic coatings and calcium-silicon plates, low tensile strength, etc., and achieve air holes The uniformity of the pore size is good, the effect of controlling the abnormal increase of the pores and increasing the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

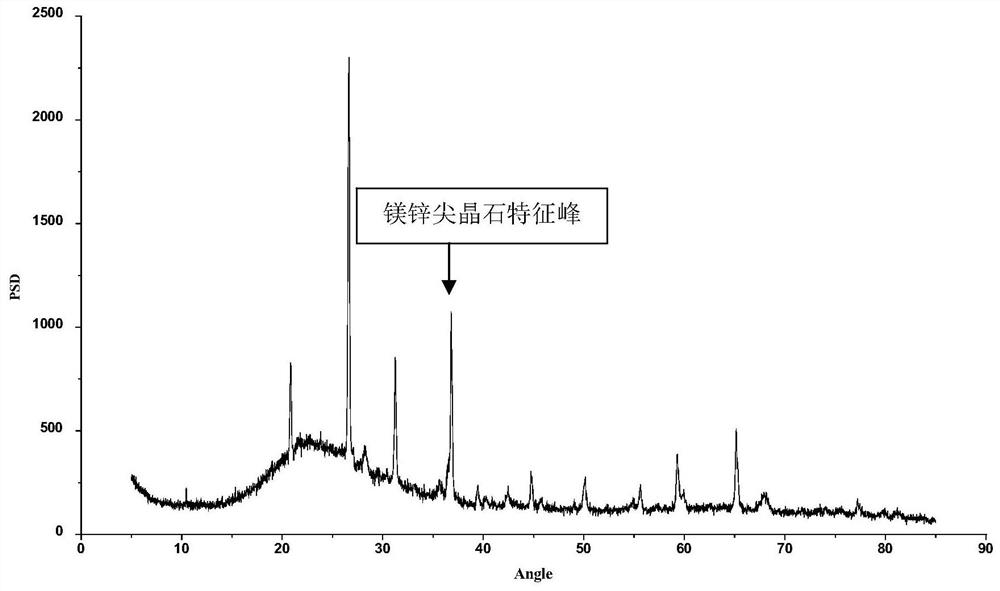

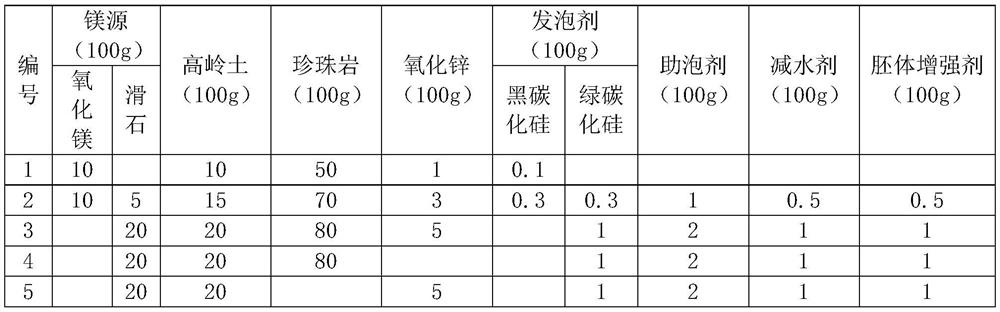

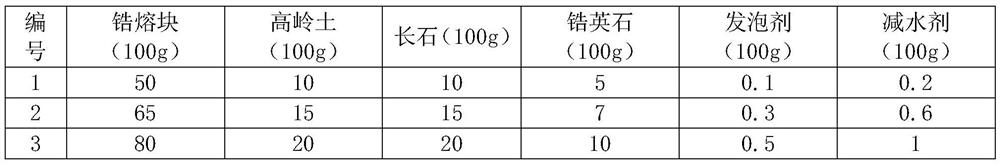

[0025] In order to clearly illustrate the technical characteristics of the present solution, the present application will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0026] As shown in the figure, in order to explain the overall concept of the application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

[0027] In addition, in the description of the present application, it should be understood that the terms "center", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal" ", "Top", "Bottom", "Inner", "Outer", "Axial", "Radial", "Circumferential" and other indicated orientations or positional relationships are based on the orientations or positional relationships shown in the drawings , is only for the convenience of describing the present application and simplifying the description, but does not indic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com