Preparation method of microporous foamed polypropylene reflecting film

A technology of microporous foaming and microporous foaming materials, which is applied in the field of preparation of microporous foamed polypropylene reflective film, can solve the problems of low diffuse reflectivity, high specular reflectivity, glare, etc., and achieve high reflectivity , good pore size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention relates to a preparation method of a microporous foamed polypropylene reflective film, comprising step 1, step 2, step 3 and step 4,

[0021] Step 1: Place the polypropylene material in the pressure vessel A, seal the pressure vessel A, raise the temperature to the infiltration temperature, the infiltration temperature is 40℃~110℃, fill the supercritical fluid to the infiltration pressure, the infiltration pressure is 1~15MPa, Then infiltrate under the infiltration temperature and infiltration pressure, and the infiltration time is 10-600min;

[0022] Step 2: The temperature of pressure vessel B is kept at the saturation temperature, and the saturation temperature is 120°C ~ 160°C, and then go through the "unload-take-install-close-fill" procedure, and the "unload-take-install-close-fill" procedure Complete within 5 minutes, then the pressure vessel B is saturated at the saturation temperature and pressure, and the saturation time is 10-60 minutes;

[002...

Embodiment 1

[0073] Place the polypropylene plate (the Mw / Mn of the polypropylene resin is 2.6, the MFR is 1.8g / 10min, the size is 40cm×40cm×2cm) in the pressure vessel A, and the pressure vessel A is sealed, the temperature is raised to 100°C, and filled with Supercritical carbon dioxide to 12MPa, then soak for 120min;

[0074] The temperature of pressure vessel B is kept at 144°C, and then undergoes the procedure of "unloading-taking-installing-closing-filling", and the completion time of the procedure of "unloading-taking-installing-closing-filling" is 115s, and then pressure vessel B is saturated Saturated under temperature and saturation pressure, the saturation time is 30 minutes, the specific steps of the "unloading-taking-installing-closing-filling" procedure are: depressurize the pressure vessel A, take out the soaked polypropylene sheet from the pressure vessel A, And put it into the pressure vessel B, seal the pressure vessel B, fill with supercritical carbon dioxide to the satu...

Embodiment 2

[0078] The same as Example 1 except that the polypropylene raw material constituting the polypropylene sheet in Example 1 was changed (the Mw / Mn of the polypropylene resin was 13.2, and the MFR was 5.7 g / 10min).

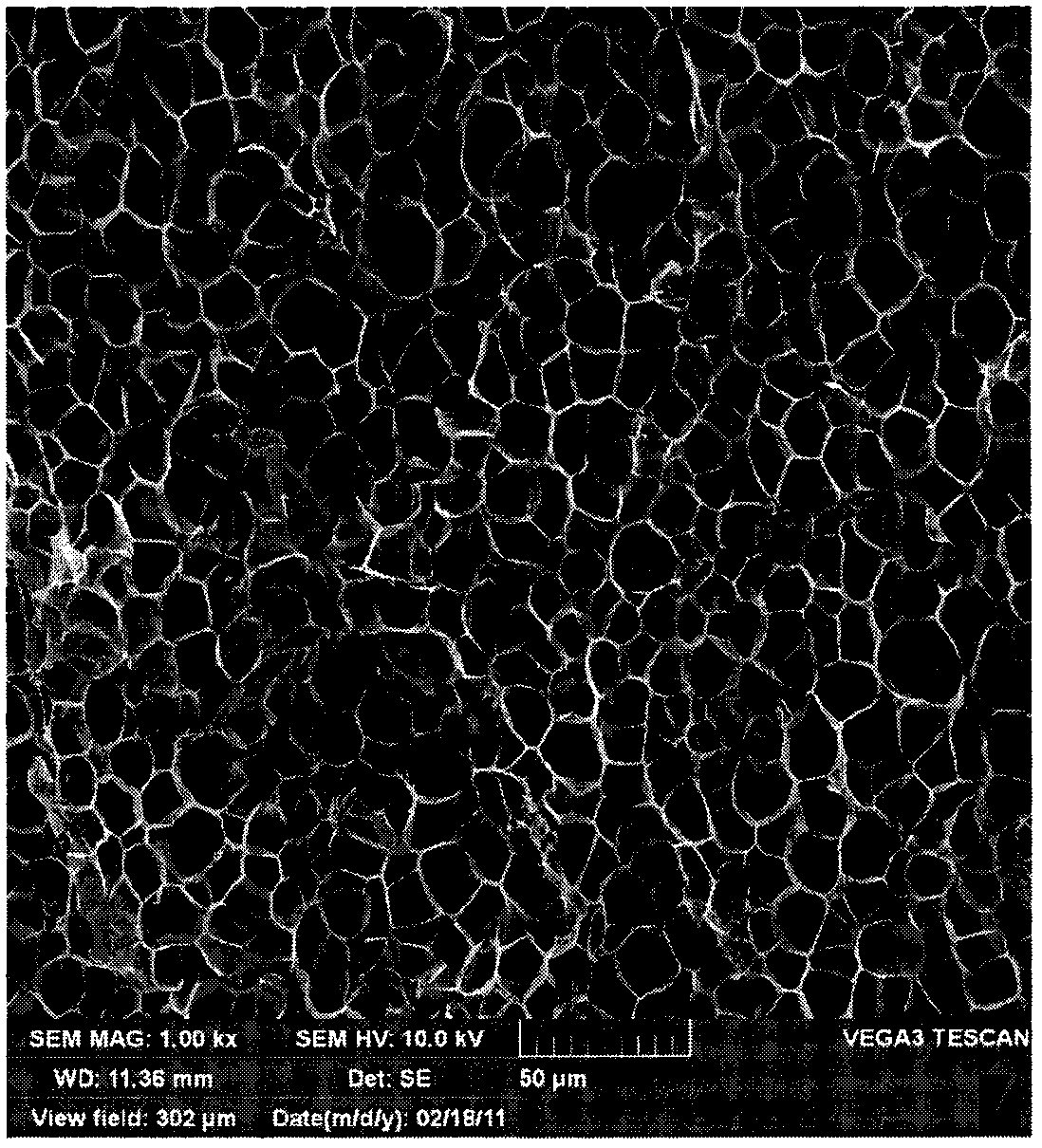

[0079] The resulting microporous foamed polypropylene reflective film has a density of 0.033g / cm 3 , and the internal cell morphology was analyzed by scanning electron microscopy, such as figure 2 As shown, the measured average pore diameter is 22 μm, the number of cells whose diameter is more than 2 times the average diameter is 1.8%, the cell uniformity is good, and the calculated cell density is 5.13×10 9 piece / cm 3 , and its reflectivity was measured to be 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com