Process for producing ordered porous anodic alumina form

An alumina template, porous anode technology, applied in anodizing and other directions, can solve problems such as unavailability, long nano-holes, etc., to achieve the effect of improving porosity, stable properties, and improving area scale and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

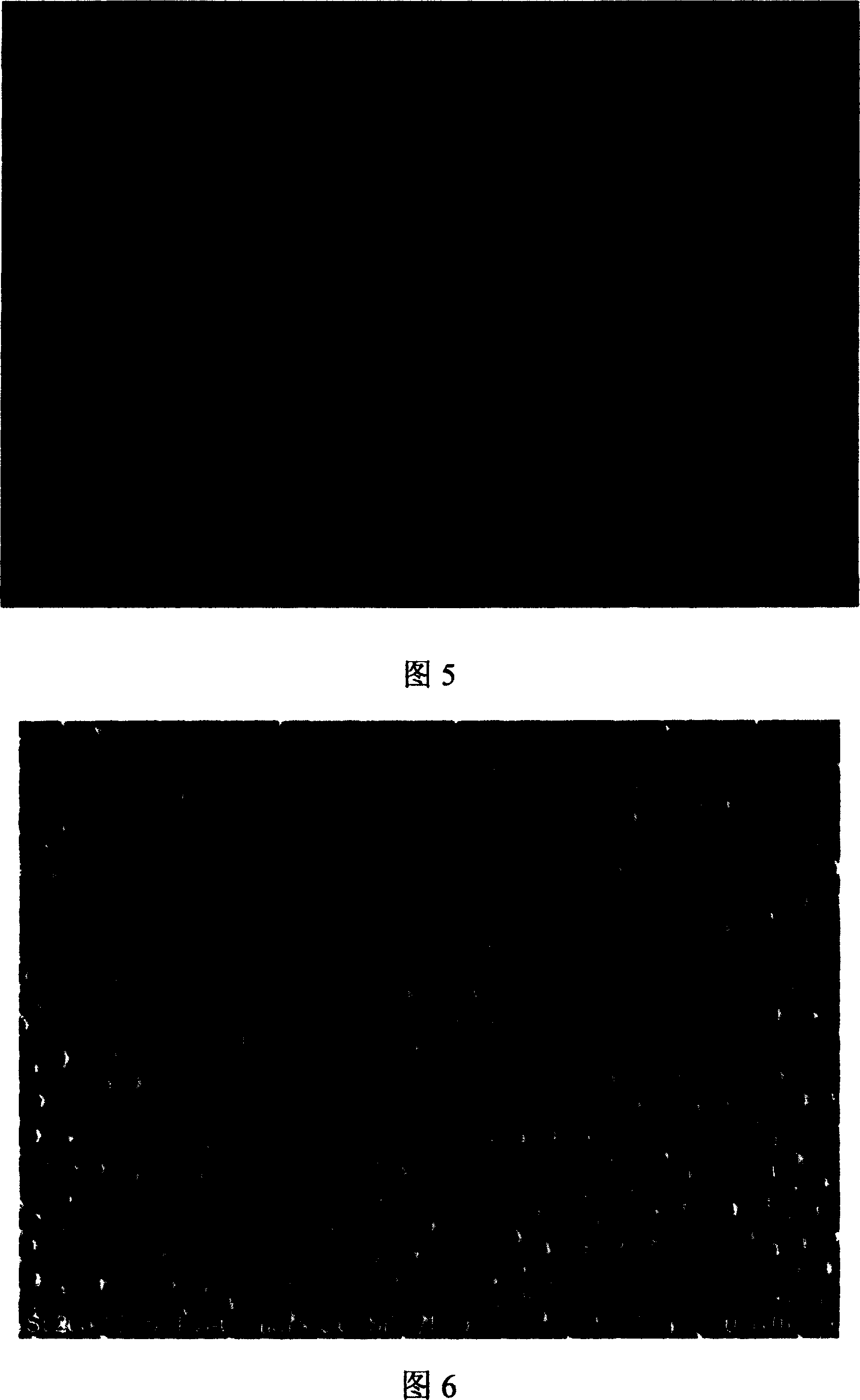

[0024] 1. Polish the aluminum sheet with a mixture of 70% perchloric acid and absolute ethanol (volume ratio 1:4) at 5°C for 10 minutes, and the voltage is 20V;

[0025] 2. After the aluminum sheet is washed with secondary water, it is first oxidized in 1.0mol / L sulfuric acid at a voltage of 20V for 2 hours, and a stainless steel plate is used as the counter electrode;

[0026] 3. Wash the aluminum sheet with a mixed solution of 6% phosphoric acid and 1.8% chromic acid at 60°C for half an hour to remove the oxide film;

[0027] 4. After the aluminum sheet is washed with secondary water, it is anodized for 5 hours with the same voltage as in step 2;

[0028] 5. Use saturated stannous oxide to peel off the aluminum matrix, use 5% phosphoric acid to expand the pores for 15 minutes, and finally store in secondary water.

Embodiment 2

[0030] 1. Polish the aluminum sheet with a mixture of 70% perchloric acid and absolute ethanol (volume ratio 1:4) at 0°C for 10 minutes at a voltage of 20V;

[0031] 2. After the aluminum sheet is washed with secondary water, it is first oxidized in 0.3mol / L oxalic acid at a voltage of 40V for 2 hours, and a stainless steel plate is used as the counter electrode;

[0032] 3. Wash the aluminum sheet with a mixed solution of 6% phosphoric acid and 1.8% chromic acid at 60°C for half an hour to remove the oxide film;

[0033] 4. After the aluminum sheet is washed with secondary water, it is anodized with the same voltage as in step 2 for 8 hours;

[0034] 5. Use saturated stannous oxide to peel off the aluminum matrix, use 5% phosphoric acid to expand the pores for 20 minutes, and finally store in secondary water.

Embodiment 3

[0036] 1. Polish the aluminum sheet with a mixture of 70% perchloric acid and absolute ethanol (volume ratio 1:4) at 3°C for 10 minutes at a voltage of 20V;

[0037] 2. After the aluminum sheet is washed with secondary water, it is first oxidized in 0.6mol / L phosphoric acid at a voltage of 110V for 1.5 hours, and a stainless steel plate is used as the counter electrode;

[0038] 3. Wash the aluminum sheet with a mixed solution of 6% phosphoric acid and 1.8% chromic acid at 60°C for half an hour to remove the oxide film;

[0039] 4. After the aluminum sheet is washed with secondary water, it is anodized with the same voltage as in step 2 for 8 hours;

[0040] 5. Use saturated stannous oxide to peel off the aluminum matrix, use 5% sulfuric acid to expand the pores for 10 minutes, and finally store in secondary water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com