Reinforced microporous filter membrane and method and device for preparing the same

A technology of microporous filtration membrane and microporous filtration membrane, applied in the field of filter materials, can solve the problems of complicated equipment, influence of film formation quality, large floor space, etc., and achieve the effects of smooth surface, large sampling flow and small filtration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, preparation casting solution

[0032] In this embodiment, four casting solution formulations with different raw material ratios as shown in Table 1 were used to prepare casting solution 4 respectively.

[0033] Table 1: Raw material formula of casting solution (unit: g)

[0034]

[0035] The concrete preparation steps of casting solution are as follows:

[0036] 1. Take the polymer resin, additive and organic solvent raw materials by the weight of the formula raw materials shown in Table 1 respectively, and then dissolve the polymer resin and additive in the organic solvent;

[0037] 2. Form a mixed solution in step 1, place it in a constant temperature water bath for stirring, and stir evenly until a clear and transparent solution is obtained;

[0038] 3. After stopping the stirring, let the clear and transparent solution stand for a period of time for defoaming;

[0039] 4. After defoaming, the solution is matured to obtain a uniform polymer soluti...

Embodiment 2

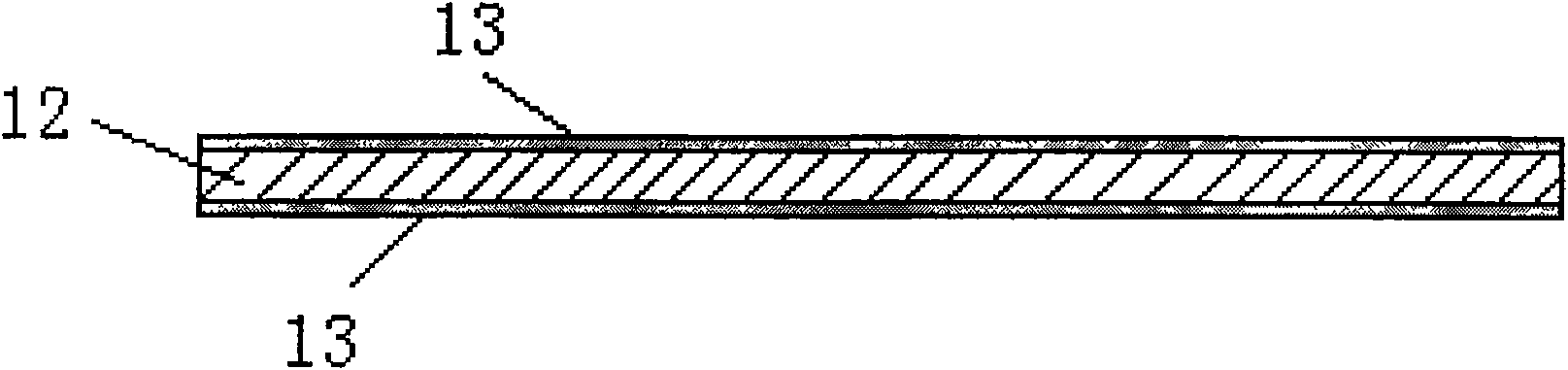

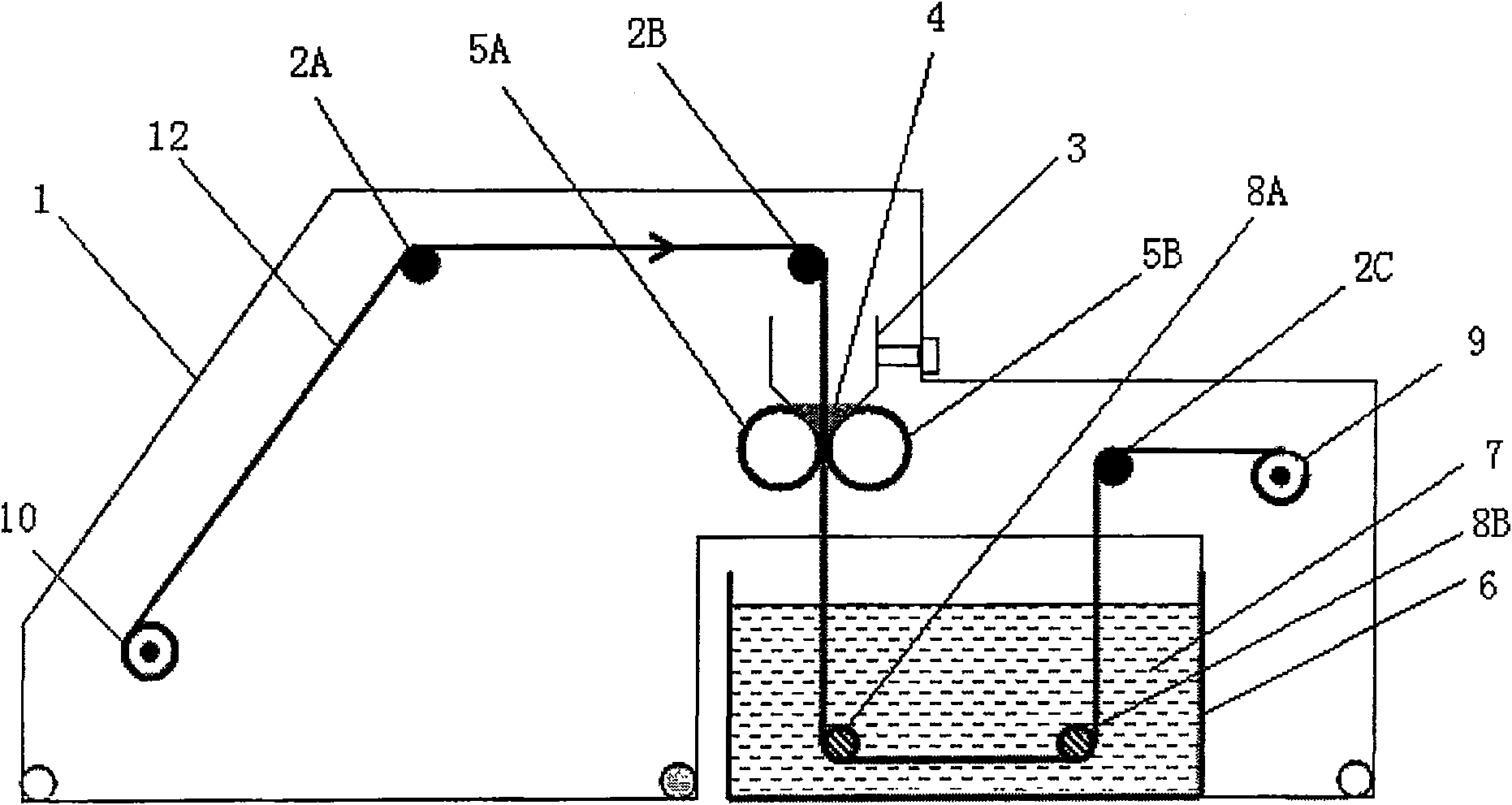

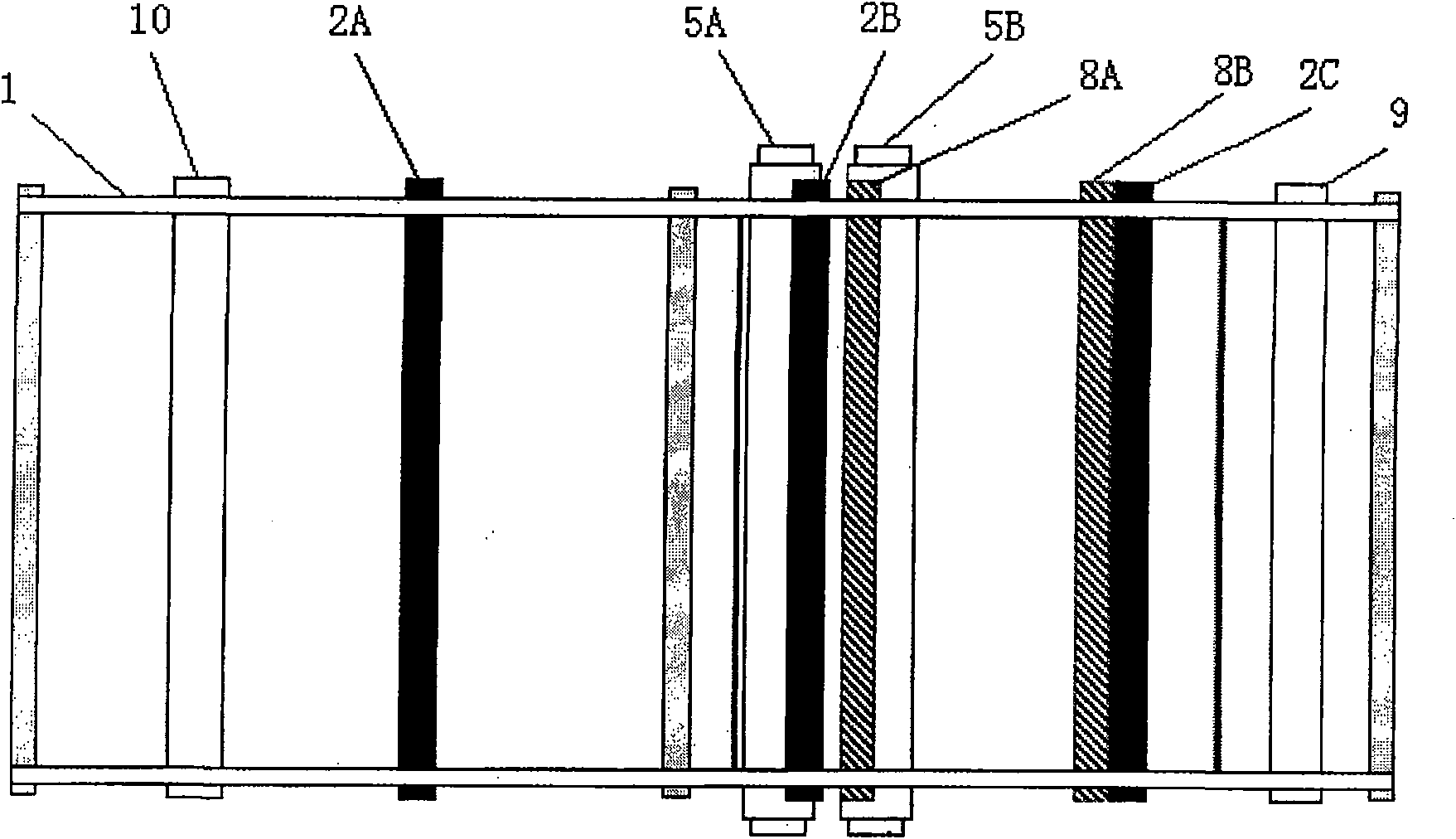

[0041] Embodiment 2, adopt device of the present invention (as figure 2 Shown) prepare the enhanced microporous filtration membrane of the present invention

[0042] First, the casting solution 4 prepared in Example 1 is injected into the film solution funnel 3, and then one end of the polyester nonwoven fabric 12 as the base is wound on the driven roller shaft 10, and the other end walks around the guide drum 2A and The guide roller 2B passes through the gap between the film liquid funnel 3 and the two film scraping rollers 5A, 5B in turn, then turns around the steering rollers 8A, 8B and the guide roller 2C, and finally wraps around the drive roller 9 . Then start the driving motor connected to one end of the driving roller shaft 9 to drive the driving roller shaft 9 to rotate, thereby pulling the polyester non-woven fabric 12 to move in the whole system.

[0043] The polyester non-woven fabric 12 continuously passes through the film liquid funnel 3 during operation, so t...

Embodiment 3

[0049] Embodiment 3: Application of the enhanced microporous filtration membrane of the present invention in sampling monitoring and filtration of α-radioactive aerosols in a high radon environment

[0050] The enhanced microporous filter membrane is used to filter aerosols in the air, including natural radon daughter aerosols and artificial radionuclide aerosols, in the monitoring of alpha radioactive aerosols in high radon environments. The aerosol collected by the enhanced microporous filter membrane is used to measure the α particle radioactivity of the aerosol in real time by the α detector located above the filter membrane. Since the filter membrane is characterized by the ability to collect most of the aerosol on the surface of the filter membrane, the energy of the alpha particles emitted by the aerosol on the filter membrane surface will remain basically unchanged (except for a small amount of absorption by the air layer. ). Usually, the energy of α particles emitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com