A kind of manufacturing method of foamed aluminum alloy

A foamed aluminum alloy and a manufacturing method, which are applied in the field of porous metal materials and can solve the problems of many pore wall defects, uneven pore size, poor pore shape of the foamed aluminum alloy, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

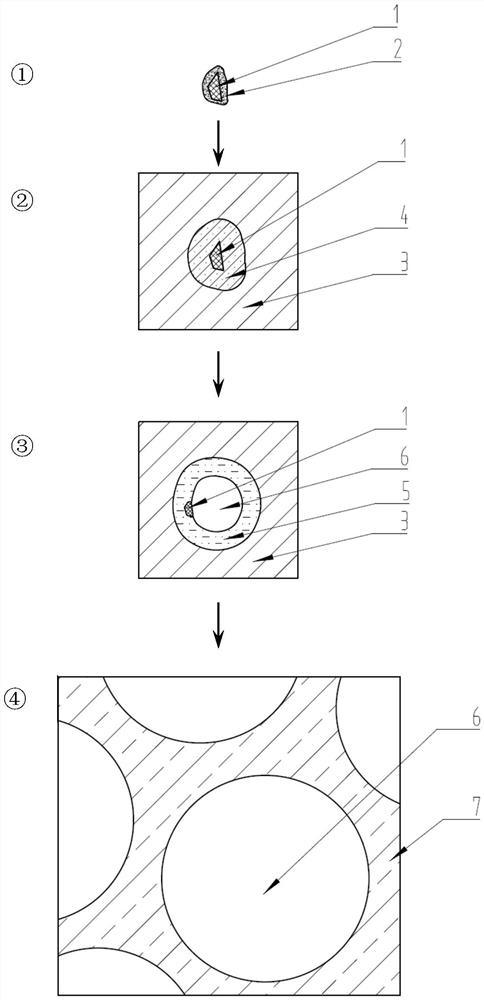

Method used

Image

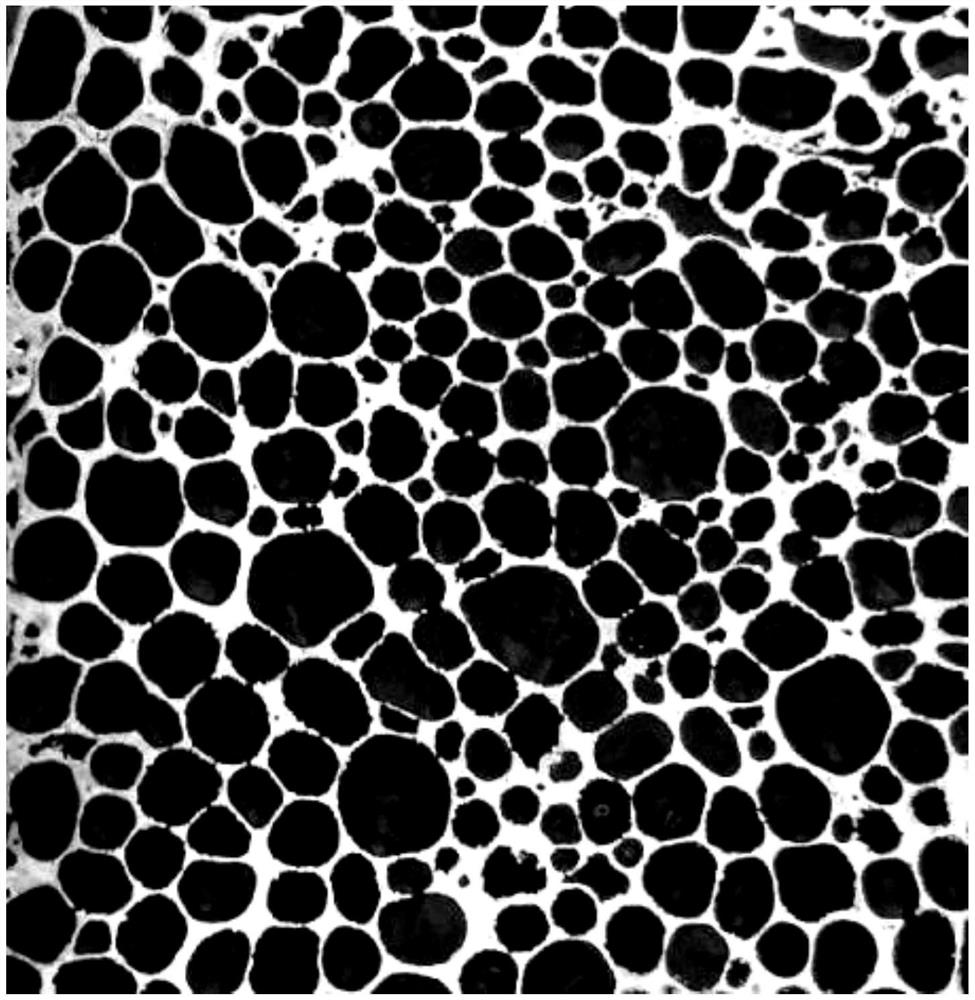

Examples

Embodiment 1

[0047] The process of preparing the foamed aluminum alloy whose alloy composition is Al-6Mg is as follows:

[0048] (1) Use TiH with an average particle size of 30 μm 2 Powder, the surface of the powder is covered with a layer of Mg metal layer by mechanical grinding method to make TiH 2 +Mg composite particles, the total weight of the powder after coating is increased by 3 times, which is equivalent to the average thickness of the Mg metal layer between 13 and 15 μm;

[0049] (2) Weigh 920g of 150 purpose pure aluminum powder (purity is 99.7%), TiH 2 +Mg composite particles 80g, making TiH 2 The mass fractions of , Mg and Al are respectively 2.0wt%, 6.0wt% and 92wt%, all of which are loaded into the mixing tank, mixed on the mixer for 8 hours, and mixed powder is made;

[0050] (3) Put the mixed powder into a steel mold and place it in a hot press, first heat the hot press to 470°C, keep it warm for 30 minutes and then press it with a pressure of 50MPa. After hot pressing,...

Embodiment 2

[0054] The process of preparing the foamed aluminum alloy whose alloy composition is Al-6Cu is as follows:

[0055] (1) Use TiH with an average particle size of 30 μm 2 Powder, the surface of the powder is covered with a layer of Cu metal layer by electroless plating method to make TiH 2 +Cu composite particles, the total weight of the powder after coating is increased by 6 times, which is equivalent to the average thickness of the Cu metal layer between 6 and 8 μm;

[0056] (2) Weigh 930g of 150 purpose pure aluminum powder (purity is 99.7%), TiH 2 +Cu composite particles 70g, making TiH 2 The mass fractions of , Cu and Al are respectively 1.0wt%, 6.0wt% and 93wt%, all of which are loaded into the mixing tank, mixed on the mixer for 8 hours, and mixed powder is made;

[0057] (3) Put the mixed powder into a steel mold and place it in a hot press. First heat the hot press to 560°C, keep it warm for 30 minutes and then press it with a pressure of 50 MPa. After hot pressing, ...

Embodiment 3

[0061] The process for preparing the foamed aluminum alloy whose alloy composition is Al-20Zn is as follows:

[0062] (1) Use TiH with an average particle size of 15 μm 2 The powder is coated with a layer of Zn metal layer on the surface of the powder by electroless plating method to make TiH 2 +Zn composite particles, the total weight of the powder after coating is increased by 10 times, which is equivalent to the average thickness of the Zn metal layer between 6 and 7 μm;

[0063] (2) Weigh 780g of 150 purpose pure aluminum powder (purity is 99.7%), TiH 2 +Zn composite particles 220g, making TiH 2 The mass fractions of , Zn and Al are respectively 2wt%, 20wt% and 78wt%, all of which are packed into a mixing tank, and mixed on a mixer for 24 hours to make a mixed powder;

[0064] (3) Put the mixed powder into a steel mold and place it in a hot press, first heat the hot press to 420°C, keep it warm for 30 minutes and then press it with a pressure of 50 MPa. After hot pressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com