Polyurethane foam for all-plastic plastic runway and preparation method thereof

A polyurethane foam and plastic track technology, applied in the field of all-plastic plastic track, can solve the problems of affecting the health of athletes, the smell of mixed track, impact absorption and vertical deformation can not be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

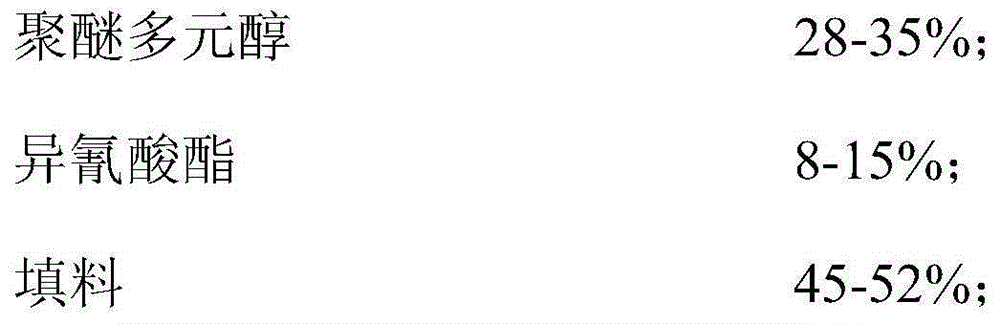

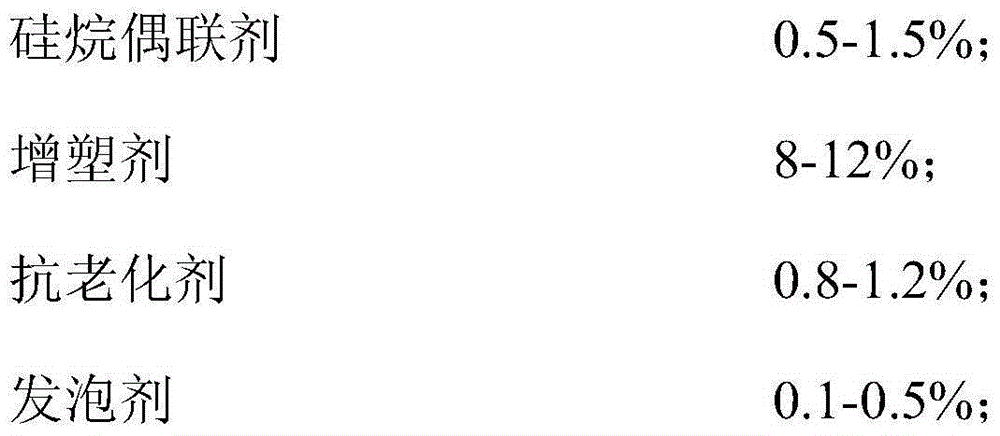

Method used

Image

Examples

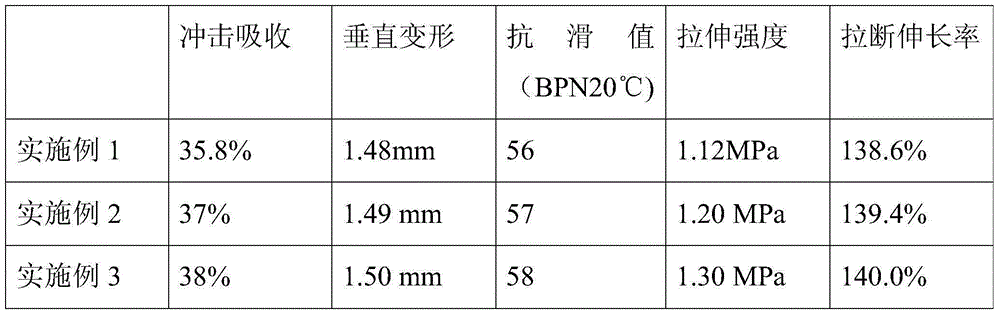

Embodiment 1

[0021] Weigh the above-mentioned 28kg polyether diol, 52kg talcum powder and 10kg plasticizer into the line for high-temperature dehydration, and then react with 8kg diphenylmethane diisocyanate at 70°C for 4 hours, and then detect the The number of isocyanates, when the number of isocyanates is 7.0, then drop 0.5kg gamma-glycidyloxypropyltrimethoxysilane into the reaction system, the number of isocyanates in the system is measured to be 5.0, and then cool down to 50- 55°C, then add 1kg of antioxidant, then cool down, filter and pack to obtain polyurethane; then add 0.5kg of foaming agent at room temperature for foaming during construction to obtain the polyurethane foam, disperse evenly after foaming, and scrape. The thickness is 5mm.

Embodiment 2

[0023] Weigh the above-mentioned 30kg polyether trihydric alcohol, 46kg quartz powder and 12kg plasticizer into the line for high-temperature dehydration, and then react with 10kg diphenylmethane diisocyanate at 65°C for 4 hours, and then detect the The number of isocyanates, when the number of isocyanates is 7.5, then add 1 kg of vinyltriethoxysilane dropwise to the reaction system, and the number of isocyanates in the system is measured to be 5.0, then cool down to 50-55 °C, and then Add 0.8kg antioxidant, then cool down and filter and pack to obtain polyurethane; then add 0.2kg foaming agent at normal temperature to foam to obtain the polyurethane foam during construction, disperse evenly after foaming and scrape, and the thickness of the coating is 5.5 mm.

Embodiment 3

[0025] Weigh the above-mentioned 35kg polyether triol, 45kg quartz powder and 8kg plasticizer into the line for high-temperature dehydration, and then react with 10kg toluene isocyanate at 65°C for 3 hours, and then detect the amount of isocyanate in the reaction system , when the number of isocyanate is 7.5, add 0.8kg of vinyltriethoxysilane dropwise to the reaction system, and the number of isocyanate in the system is measured to be 5.5, then lower the temperature to 50-55°C, and then add 1.1kg Ultraviolet absorber, then cool down, filter and package to obtain polyurethane; then add 0.1kg foaming agent at room temperature to foam to obtain the polyurethane foam during construction, disperse evenly after foaming, and scrape with a thickness of 6.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com