Antifreezing foaming drainage agent, and preparation method and application thereof

A foam drainage agent and reaction container technology, which is applied in chemical instruments and methods, earthwork drilling, and fluid extraction, etc., can solve the problems of inability to perform drainage and gas extraction, affect normal production, and produce unstable production, and improve thermal stability. and salt tolerance, good compounding and synergistic effect, the effect of lowering freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides an antifreeze foam drainage agent.

[0030] In terms of weight percentage, the raw material composition of the antifreeze foam drainage agent is: fatty alcohol polyoxyethylene ether phosphate sodium salt 30%, α-olefin sodium sulfonate 20%, polyanionic cellulose 2.5%, coconut acid diethanolamide 1.5%, ethylene glycol 3%, potassium carbonate 1.5%, sodium chloride 1.2%, urea 0.8%, sodium acetate 0.6%, and the balance is water.

[0031] The preparation steps of the foaming agent in the present embodiment are as follows:

[0032] (1) Add fatty alcohol polyoxyethylene ether phosphate sodium salt and α-olefin sulfonate sodium into the reaction kettle successively, stir at normal temperature for 25 minutes, and the stirring speed is 300 rpm;

[0033] (2) Add polyanionic cellulose and coconut acid diethanolamide successively in above-mentioned reactor, stir 15 minutes at normal temperature, stirring speed is 300 rev / mins;

[0034] (3) Add ethylene glyc...

Embodiment 2

[0066] This embodiment provides an antifreeze foam drainage agent.

[0067] In terms of weight percentage, the raw material composition of the antifreeze foam drainage agent includes: fatty alcohol polyoxyethylene ether phosphate sodium salt 25%, α-olefin sodium sulfonate 15%, polyanionic cellulose 2%, coconut acid diethanolamide 1%, isopropanol 2%, potassium carbonate 1.2%, sodium chloride 1%, urea 0.6%, sodium acetate 0.5%, and the balance is water.

[0068] The preparation steps of antifreeze foam drainage agent in the present embodiment are as follows:

[0069] (1) Add fatty alcohol polyoxyethylene ether phosphate sodium salt and α-olefin sulfonate sodium successively into the reaction kettle, stir at normal temperature for 20 minutes, and the stirring speed is 200 rpm;

[0070] (2) Add polyanionic cellulose and coconut acid diethanolamide successively in above-mentioned reactor solution, stir 10 minutes at normal temperature, stirring speed is 200 rev / mins;

[0071] (3)...

Embodiment 3

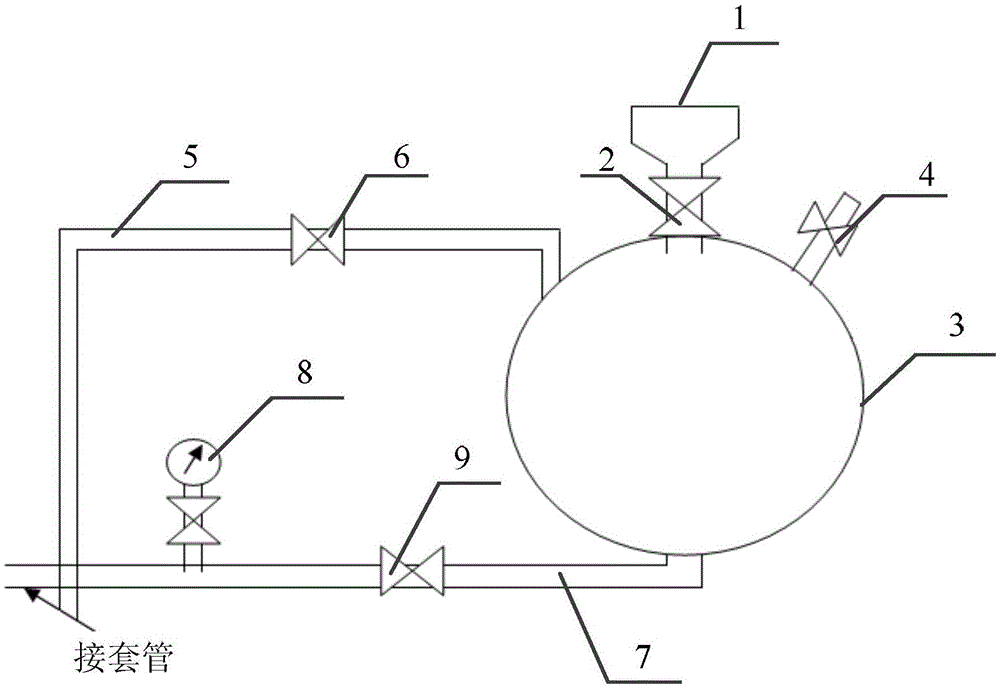

[0103] The antifreeze foam drainage agent that above-mentioned embodiment 1 and 2 provides is applied in the drainage gas recovery of natural gas well, utilizes wellhead dosing tank (such as figure 1 As shown), the liquid antifreeze foam drainage agent is added into the wellbore from the casing. After the pressure is balanced, the liquid flows to the bottom of the well by its own gravity, mixes with the fluid at the bottom of the well, and generates foam after being agitated by the air flow, thereby reducing the The back pressure at the bottom of the well is improved, the water-carrying capacity of the gas flow is improved, and the purpose of increasing natural gas production is achieved.

[0104] The construction steps of dosing (adding antifreeze foam drainage agent) to the casing of natural gas wells are as follows:

[0105] 1) Close the outlet valve (9) and balance valve (6) of the dosing tank (3), and open the emptying valve (4) to empty;

[0106] 2) Open the feeding inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com