Light high-strength polylactic acid foam material and method for preparing same

A technology of foam materials and polylactic acid, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of low PLA melt strength, high PLA foam density, and limitations on PLA applications, and achieve isolation Precise control of thermal properties, high foaming efficiency, and precise control of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

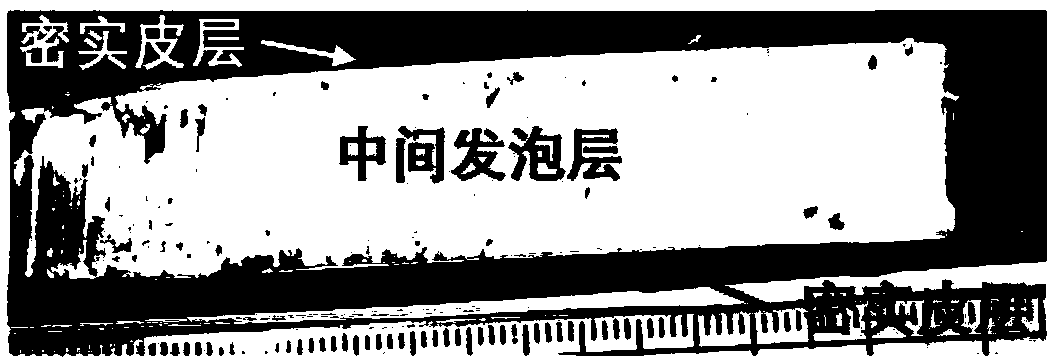

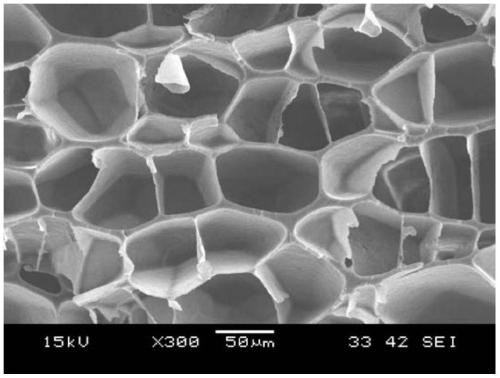

[0066] A kind of method for preparing lightweight high-strength polylactic acid foam material, raw material is PLA, and its density is 1.24g / cm 3 (@23°C), the melt flow index is 10g / 10min; the modified filler is 100 mesh solid powder PTFE; the nucleating agent is 3000 mesh talc powder; the foaming agent used is supercritical carbon dioxide with a purity of 99.9%.

[0067] The method comprises the steps of:

[0068] (1) PLA, PTFE, and talcum powder were blended in a ratio of 96:1:3 by mass percentage to obtain a PLA-based compound;

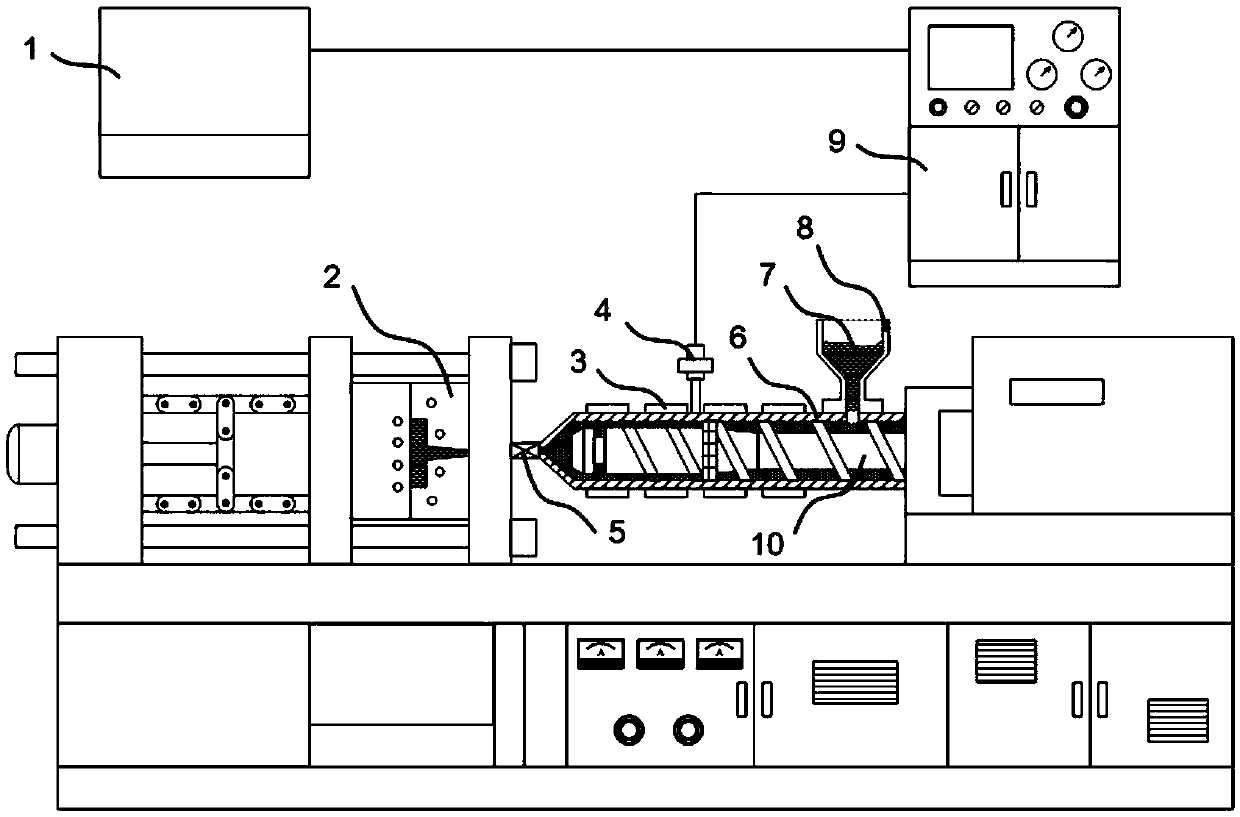

[0069] (2) Add the PLA-based compound obtained in step (1) into a microcellular foaming injection molding machine, and under the double action of the shearing of the screw of the injection molding machine and the heating of the barrel, the PLA-based compound is gradually plasticized and melted, and plasticized The temperature of the PLA-based composite melt after melting is 220°C, and the pressure of the PLA-based composite melt during the plastic...

Embodiment 2

[0076] A kind of method for preparing lightweight high-strength polylactic acid foam material, raw material is PLA, and its density is 1.24g / cm 3 (@23℃), the melt flow index is 60g / 10min; the modified filler is 1000 mesh solid powder PTFE; the nucleating agent is 10000 mesh montmorillonite powder; the foaming agent used is supercritical carbon dioxide with a purity of 99.9% .

[0077] The method comprises the steps of:

[0078] (1) PLA, PTFE, and montmorillonite were blended in a ratio of 77:8:15 by mass percentage to obtain a PLA-based composite;

[0079] (2) Add the PLA-based compound obtained in step (1) into a microcellular foaming injection molding machine, and under the double action of the shearing of the screw of the injection molding machine and the heating of the barrel, the PLA-based compound is gradually plasticized and melted, and plasticized The temperature of the PLA-based composite melt after melting is 170°C, and the pressure of the PLA-based composite melt ...

Embodiment 3

[0086] A kind of method for preparing lightweight high-strength polylactic acid foam material, raw material is PLA, and its density is 1.24g / cm 3 (@23°C), the melt flow index is 40g / 10min; the modified filler is 10,000 mesh solid powder PTFE; the nucleating agent is 5,000 mesh calcium carbonate powder; the foaming agent used is supercritical nitrogen with a purity of 99.9%.

[0087] The method comprises the steps of:

[0088] (1) PLA, PTFE, and calcium carbonate powder are blended in a ratio of 82:15:3 by mass percentage to obtain a PLA-based composite;

[0089] (2) Add the PLA-based compound obtained in step (1) into a microcellular foaming injection molding machine, and under the double action of the shearing of the screw of the injection molding machine and the heating of the barrel, the PLA-based compound is gradually plasticized and melted, and plasticized The temperature of the PLA-based composite melt after melting is 210°C, and the pressure of the PLA-based composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com