Liquid foaming backfilling material for toilet and preparation method thereof

A toilet and liquid technology, applied in the field of foamed cement, can solve the problems of complicated toilet backfill construction, and achieve the effects of strong flowability, high surface strength and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare raw materials according to the ratio of parts by mass: 280 parts of ordinary Portland cement of grade 32.5, 1 part of animal cement foaming agent, 3 parts of calcium formate, 1 part of water-repellent calcium stearate, and 1.5 parts of water-retaining agent hydroxyethyl cellulose 1 part, 1 part of polypropylene fiber, 0.8 part of thickener organic bentonite, 200 parts of water.

[0033] The steps of foaming backfilling at the backfilling site are: (1) First pour water into the container of the mixer in proportion.

[0034] (2) After adding the animal cement foaming agent in the formula into the container, stirring and foaming at a rotating speed of 300-400r / min until the volume of the foam is 450% of the volume of the added water.

[0035] (3) Mix calcium formate, hydroxyethyl cellulose, acrylic fiber, calcium stearate, and thickeners evenly and add them to the container. After stirring evenly, put in cement for stirring. After stirring evenly, a Toilet liquid ...

Embodiment example 2

[0037] Prepare raw materials according to the ratio of parts by mass: 300 parts of ordinary portland cement of grade 32.5, 1.5 parts of plant cement foaming agent, 4 parts of calcium formate, 4 parts of water-repellent WACKER water-repellent rubber powder, water-retaining agent hydroxyethyl cellulose 1 part, 1 part of polypropylene fiber, 1.0 part of thickener diatomaceous earth, 220 parts of water.

[0038] The steps of foaming backfilling at the backfilling site are: (1) First pour water into the container of the mixer in proportion.

[0039] (2) After adding the plant cement foaming agent in the formula into the container, stirring and foaming at a rotating speed of 300-400r / min until the volume of the foaming is 450% of the volume of the added water.

[0040] (3) Mix calcium formate, water-repellent WACKER water-repellent rubber powder, water-retaining agent hydroxyethyl cellulose, polypropylene fiber, and thickener diatomaceous earth, mix them evenly, add them into the co...

Embodiment example 3

[0042]Prepare raw materials according to the ratio of parts by mass: 300 parts of ordinary Portland cement of grade 42.5, 1.2 parts of liquid foaming aid, 4 parts of calcium formate, 3 parts of water-repellent agent, 2 parts of water-retaining agent, 0.8 part of polypropylene fiber, 1 part of thickening agent, 230 parts of water: the liquid foaming aid is selected from animal cement foaming agent and vegetable cement foaming agent according to the compound foaming agent in any proportion. The water retaining agent is hydroxyethyl cellulose. The water-repellent agent is WACKER water-repellent rubber powder. The thickener is sodium bentonite.

[0043] The steps of foaming backfilling at the backfilling site are: (1) First pour water into the container of the mixer in proportion.

[0044] (2) After adding the liquid foaming aid in the formula into the container, stirring and foaming at a rotating speed of 300-400 r / min until the volume of foaming is 450% of the volume of the ad...

PUM

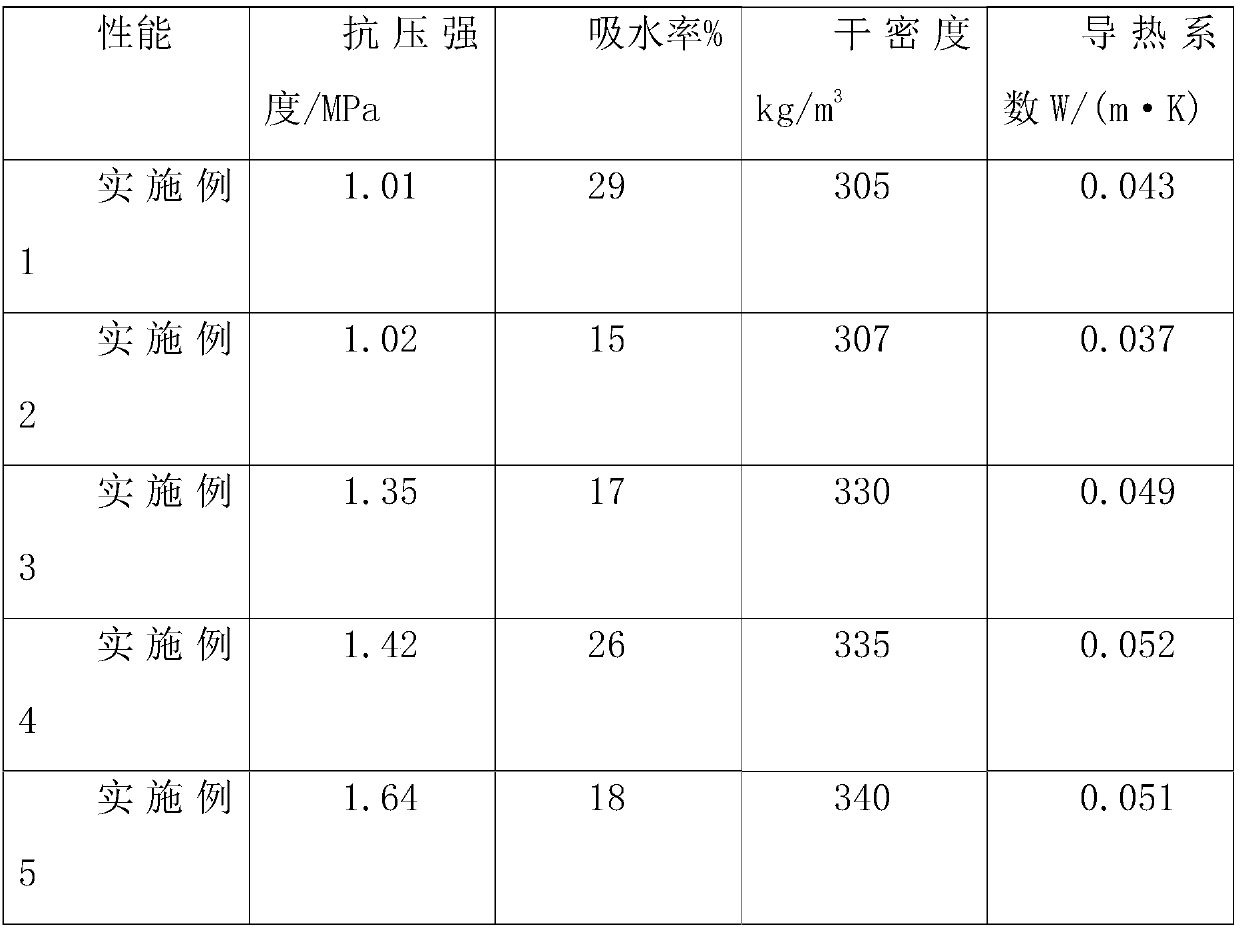

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com